April 2024

|

Search the FOA website

FOA Home Page

Contact

Us

|

Sign

up for the FOA eMail Newsletter

Privacy Policy

Links To Sections

News

Technical

Worth

Reading Q&A

Training/FiberU

Resoures

Safety

About

|

INDEX

Newsletter Sections Click

on any link to jump to that section

Features

April 1 - A Day For Jokes

AI To Write International Standards

Drone Guided By Fiber Optics

Technology Burnout

AI Generated Spam

Data Centers, AI, Crypto Overload Power Grid

FOA Support For STEM Education

All FOA Certification Credentials Are Online

Links To Resources On Broadband

News

FTTH Award Goes To FOA Instructor

Ian Gordon Fudge

CFOTs Are Everywhere - Even Mt. Fuji

Getting Trained & Certified In India

New FTTH Textbook in Serbian Language

Broadband Communities Summit

Technical

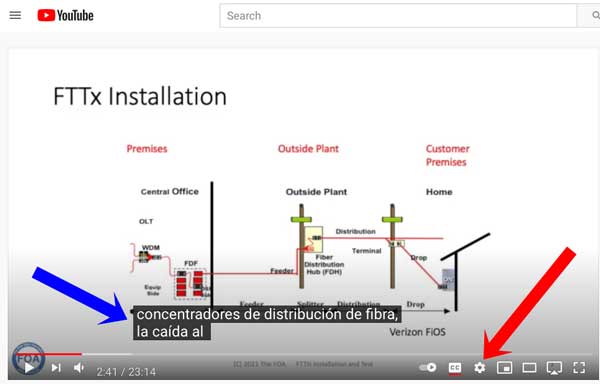

Introduction To Fiber Project Softwaare

Fiber To The Shore

Best Example Of Worst Install?

Spike Markers For Underground Cables

NECA/FOA Standard Withdrawn

Information From A Cable Scrap

Managing Projects - Gantt Charts

FOA Color Code Guides

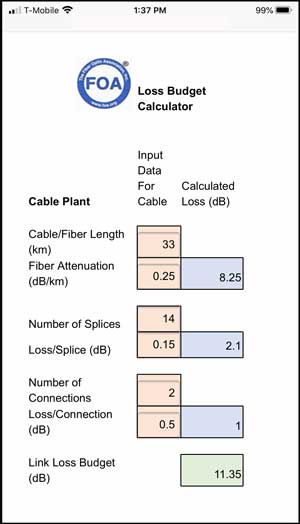

FOA Online Loss Budget Calculator

Worth

Reading Lots of interesting

articles

Q&A

Interesting questions from our readers

Training/FiberU

Types Of Work Done By Fiber Techs

FOA-Approved School News

Fiber U

MiniCourses

Resources

New FOA Technical Resources

Safety

About the FOA

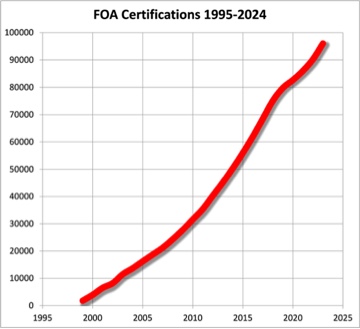

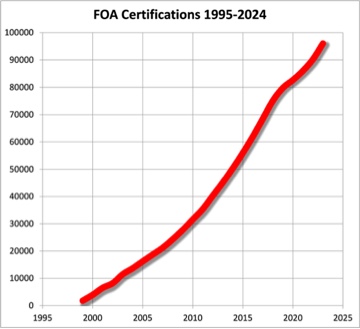

FOA Certified Techs:

2024 At FOA - Heading For 100,000

Time

To Renew Your FOA Certifications?

Jobs

- See FOA Jobs

Web Page and FOA on

- The FOA Jobs

- Using your FOA

Training/Certification to Find the Right Job

in Fiber Optics

Where

Are The Jobs In Fiber Optics?

Join The FOA eMail Newsletter

List

Want

to be notified when the FOA Newsletter is updated? Sign

up for the FOA eMail Newsletter.

Trademarks:

The FOA logo and name, CFOT® (Certified Fiber Optic Technician) and

Fiber U® (the FOA online learning site) are

registered trademarks of the FOA.

Want to know more about fiber optics?

Looking for specific information? Here's the largest

technical reference on the web: The

FOA Online Fiber Optic Reference Guide.

Free online self-study programs

on many fiber optics and cabling topics are

available at Fiber U,

FOA's online web-based training website.

FOA

Reference Books

Available Printed or eBooks

The fiber book is

available in Spanish and French

Click on any of

the books to learn more.

- Fiber

Optic Safety Poster to download and

print

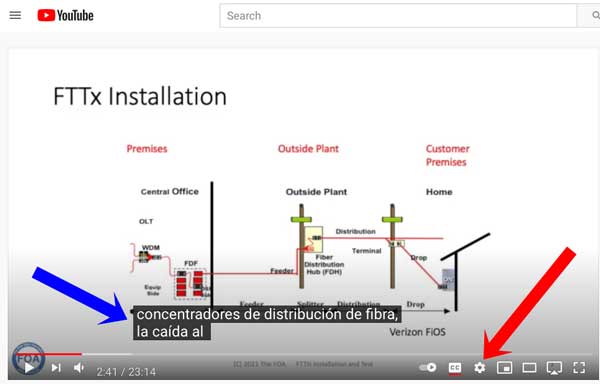

FOA Videos on

FOA

is a member of:

The FOA Newsletter is

edited by Jim Hayes - send your stories, leads,

ideas, comments to <jim @ foa.org>

Search the FOA Website With

DuckDuckGo

- The Archives: Past

Issues.

- Use these links to

read past issues or use FOA's

Custom Search to look for specific

topics on our website.

- 1/24, 2/24, 3/24, 4/24.

1/23, 2/23, 3/23, 4/23, 5/23, 6/23, 7/23, 8/23, 9/23, 10/23, 11/23, 12/23

1/22, 2/22, 3/22, 4/22, 5/22, 6/22, 7/22, 8/22, 9/22, 10/22, 11/22, 12/22

1/21, 2/21. 3/21, 4/21, 5/21, 6/21, 7/21, 8/21, 9/21, 10/21,

11-12/21,

1/20,

2/20,

3/20.

4/20,

5/20,

6/20,

7/20,

8/20,

9/20,

10/20,

11/20,

12/20,

1/19,

2/19,

3/19,

4/19, 5/19, 6/19, 7/19, 8/19, 9/19,

10/19,

11/19,

12/19

1/18,

2/18,

3/18, 4/18,

5/18, 6/18, 7/18, 8/18, 9/18, 10/18,

12/18.

1/17, 2/17, 3/17, 4/17, 5/17, 6/17,

7/17,

8/17,

9/17,

10/17, 11/17,

12/17

1/16, 2/16, 3/16,

4/16,

5/16,

6/16,

7-8/16,

9/16,

10/16,

11/16,

12/16

1/15,

2/15,

3/15,

4/15,

5/15,

6/15,

7/15,

8/15,

9/15 ,

10/15,

11/15

, 12/15

1/14,

2/14,

3/14,

4/14,

5/14,

6/14,

7/14,

8/14,

9/14,

10/14,

11/14,

12/14

1/13,

2/13,

3/13,

4/13,

5/13, 6/13,

7/13,

8/13,

9/13,

10/13,

11/13,

12/13

1/12

, 2/12,

3/12,

4/12,

6/12,

7/12,

8/12,

9/12,

10/12,

11/12,

12/12

1/11 ,

2/11,

3/11,

4/11,

6/11,

7/11,

8/11,

9/11, 10/11,

11/11,

12/11,

1/10 ,

2/10,

3/10,

4/10,

05/10,

07/10,

08/10,

09/10,

10/10,

11/10

1/09 ,

2/09,

3/09,

04/09,

05/09,

07/09,

08/09,

09/09,

10/09, 11/09,

12/09

1/08 , 2/08, 3/08, 4/08, 5/08, 6/08, 7/08, 8/08, 09/08, 10/08, 11/08, 12/08

12/07 , 11/07, 10/07, 09/07, 08/07, 07/07, 06/07, 05/07, 04/07, 03/07, 2/07, 1/07

12/06 , 11/06, 10/06, 09/06, 8/06, 7/06, 6/06, 5/06, 4/06, 3/06, 2/06, 1/06,

12/05 ,11/05, 10/05, 09/05, 08/05, 07/05, 6/05, 5/05, 4/05, 2/05, 01/05,

12/04 , 10/04, 9/04, 8/04, 7/04, 6/04, 5/04, 4/04, 3/04, 1/04,

12/03 , 11/03 10/03 9/03, 8/03, 7/03, 6/03, 3/03, 10/02 , 8/02, 5/02

Current Issue of FOA

Newsletter

Time To Renew Your

FOA Certifications?

To

keep your FOA certifications active, you need to

renew them when they expire every 3 years. Now we have a new more

convenient way to renew - an online store at Paypal

- where you can quickly and conveniently use your

PayPal account or your credit card to renew your

certifications.

- Renew

online with a credit card or PayPal

-

Join FOA On

Social Media

FOA

has 3 LinkedIn Groups

FOA

- official page on LinkedIn - covers FOA, technology and jobs in the fiber optic

marketplace

FOA

Fiber Optic Training - open to all, covers

fiber optic technology and training topics

Grupo

de La Asociación de Fibra Óptica FOA (Español)

|

April 1st Is A Day For Jokes -

But Can You Tell Which Are Jokes And Which Are Real?

It is traditional to use April 1st - April Fool's day - as a day to

create jokes, the more outrageous but believable the better. One of the

best for the fiber optic community was Google TISP

- the first Google fiber to the home offering, where they mail you a

package with a fiber optic cable that you install yourself by flushing

it down your toilet! Amazing how many people believed that one was real!

So this month in the FOA Newsletter we're going to run some stories that

might be true, might not. Read them and guess. We'll provide a link at

the end for you to check your guess.

AI To Write International Standards

An Artificial Intelligence (AI) called ISObot that

is capable of writing new industry standards has been introduced.

Created by a consortium of standards groups, ISObot is designed to write

industry standards on any subject. ISObot was trained first on the

thousands of standards already in existence so it would first learn the

structure, language of standards and the format. Then it was trained

on relevant articles on the Internet and applications literature of

companies involved with the topics of the standards being created and which would be expected to write the relevant standards.

A spokesperson for the creators said, "ISObot can

write standards as well as any of the current standards committees. Even

better it means no more debating in long committee meetings or backroom

maneuvering to get standards for any topic. It also reduces the time to

write a standard. ISObot can write a standard in a few minutes that

might take a committee years to create, given the need for agreement

among the committee members. The standards members who have seen the

results of ISObot think the resulting standards are as good as the ones

they create, but they are complaining that there is no longer any excuse

to travel to exotic locations to have meetings."

ISObot's first fiber optic standard is the

standard for OSP aerial cable plants. The development of the standard

had a steep learning curve; one iteration confused pole location and

service loops, leading to occasional curlicues in the layout of cables

and service loops partially buried in the ground. Confusion over the

word fiber also resulted in including a specification for the tension on

yarn strung between poles. But all the bugs have now been worked out

and the final standard will be released on April 1, 2024.

Soon ISObot will produce international standards that

cover any and everything, from fiber optics to electrical vehicles to

AI. Yes ISObot will write standards that cover itself.

Drone Guided By Fiber Optics

The Ukrainian Army recently captured a Russian drone which communicates

via a fiber-optic link instead of radio, making it jam-proof.

Highlighted in red is the plastic egg and spool of fiber it holds.

Ukrainian military reported this strange new type of Russian drone, in

addition to the usual warhead, was carrying a hollow plastic egg

containing optical fiber that spooled out behind the drone and provided a

communications link to its operator.

Kalashnikov subsidiary ZALA boasted that their new ‘Product 55’

quadcopter was proof against all forms of radio jamming. The Russian

attack drone uses a very different and quite surprising technology to

overcome radio interference and jamming: it has no radio but

communicates with the operator via a fiber-optic cable spooled out as it

flies.

This was the concept behind the U.S. Fiber Optic Guided Missile (FOG-M)

program from the 1980s. Being able to see from the missile’s point of

view meant the operator could engage targets beyond their line of sight;

a light vehicle carrying racks of EFOG-Ms would be able to destroy

enemy armor a long range.

Is this fiber optic guided drone real? Find out here.

Technology Burnout

The technology industry felt like an island of bubbly optimism about

its future and ours. Faith in the magic of technology was painfully

earnest — and refreshing.

But we’ve changed and the technology industry has changed.

There has been a slow metamorphosis of America’s technology industry

from David to Goliath. Along with it, the zesty confidence of the early

2010s has curdled. Our bubbly faith in technology is now tempered by

mistrust and resentments.

That shift was spotlighted this week by a landmark European law trying

to wrest power from Big Tech, fresh allegations that Meta repeatedly

failed to help people whose social media accounts were hijacked by

scammers and a fight between rich tech executives over artificial

intelligence that’s more about their self interest than our needs.

Many of us are grateful for technology and hope it can help us solve

thorny problems. We also fear that many technologies and tech companies

are making us and the world worse. We’ve become more worried than

hopeful about inventions like AI.

Our feelings about technology may not be facts. But they do influence

how we view technology and the world around us. And there’s no turning

back to the fresh optimism I felt years ago.

AI Generated Spam

The following AI written email was received by FOA President Jim Hayes:

From: Chip Minto

Subject: Let's consider focused insights: B Generous

Hi Jim,

Your dedication to promoting fiber optics through education and

certification at FOA is truly commendable. As Chip, Director of Lending

and Partnerships at B Generous, I've seen organizations like OFS and

Corning thrive by staying ahead with our market trends.

FOA's impact in the industry, particularly your recent initiatives, have

caught our attention. The resilience highlighted in recent reviews

showcases your commitment to excellence and innovation.

In our quest for futuristic solutions, we invite you to an exclusive

strategy session tailored for FOA. Dive into a world of possibilities

with us in a 20-30 minute chat using the FOA invitation deck. Join the

ranks of the 221+ in this unique journey towards success.

Wishing you a week filled with inspiration and growth.

______________________

Chip Minto

Director of Lending and Partnerships

B Generous

United States.

Kalendar.AI sales agents have written & sent this email on behalf of

B Generous as they've requested us to send this to you. If you no

longer wish to receive these emails, simply unsubscribe to never hear

from them again, respond to them here, or let us know if you find any

errors in the AI content generation with your kind, big heart. We only

process publicly available information limited to Name (first and last)

and company information (location, the domain, website metadata such as

technology, and any relevant keywords). We DO NOT track or store any of

your personal information. Please visit our TLDR privacy if you want to

understand more about how we process data. Our mission is to help

businesses create opportunities, particularly helping small businesses

to thrive with the help of AI-driven stories. We strictly comply with

CCPA, GDPR, and CAN-SPAM laws. You can opt-out of our data processing

anytime. We are Kalendar Inc, located at 450 Lexington Ave. New York, NY

10017.

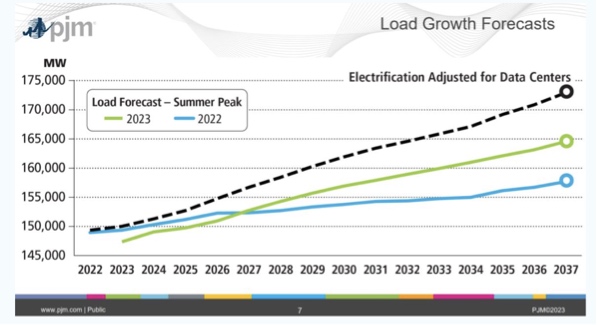

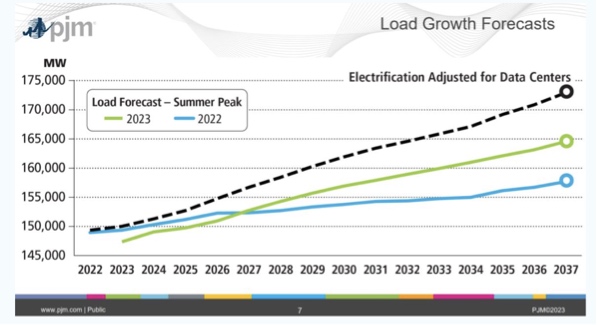

Data Centers, AI, Crypto To Cause Power Grid Overload

Amid explosive demand, America is running out of power - AI and the boom

in clean-tech manufacturing are pushing America’s power grid to the

brink. Utilities can’t keep up.

Vast swaths of the United States are at risk of running short of

power as electricity-hungry data centers and clean-technology factories

proliferate around the country, leaving utilities and regulators

grasping for credible plans to expand the nation’s creaking power grid.

Data center growth is being driven by the increase in streaming video,

but in addition the massive computing power needed for AI and Bitcoin

mining.

The soaring demand is touching off a scramble to try to squeeze more

juice out of an aging power grid while pushing commercial customers to

go to extraordinary lengths to lock down energy sources, such as

building their own power plants.

“When you look at the numbers, it is staggering,” said Jason Shaw,

chairman of the Georgia Public Service Commission, which regulates

electricity. “It makes you scratch your head and wonder how we ended up

in this situation. How were the projections that far off? This has

created a challenge like we have never seen before.”

A major factor behind the skyrocketing demand is the rapid innovation in

artificial intelligence, which is driving the construction of large

warehouses of computing infrastructure that require exponentially more

power than traditional data centers. AI is also part of a huge scale-up

of cloud computing. Tech firms like Amazon, Apple, Google, Meta and

Microsoft are scouring the nation for sites for new data centers, and

many lesser-known firms are also on the hunt.

The proliferation of crypto-mining, in which currencies like bitcoin are

transacted and minted, is also driving data center growth. It is all

putting new pressures on an overtaxed grid — the network of transmission

lines and power stations that move electricity around the country.

Bottlenecks are mounting, leaving both new generators of energy,

particularly clean energy, and large consumers facing growing wait times

for hookups.

Are the future problems of the power grid real or a joke? Find out here.

These stories

might be true, might not. Read them and guess. Find out here.

The rest of the FOA April Newsletter is guaranteed to be legitimate news!

FOA Programs Support STEM Education

Classroom

Resources For STEM Teachers In K-12 And Technical Schools Classroom

Resources For STEM Teachers In K-12 And Technical Schools

Teachers in all grades can introduce their students to fiber

optic technology with some simple demonstrations. FOA has

created a page for STEM or STEAM (science, technology,

engineering, arts

and math) teachers with materials appropriate to their

classes. Fiber

Optic Resources For STEM Teachers.

FOA

also has a YouTube

Video on "Careers

in Fiber Optics" and a "Careers

In Fiber Optics" Website.

See below.

All FOA

Certification Credentials Are Now Online

All FOA Certified Fiber Optic Technicians now have their certification

credentials online.

if your FOA certification has not expired you should have been notified you have an

online credential. If you did not get notification it may be because

FOA did not have a valid email for you. Contact FOA to inquire about your certification credential.

Whats New?

The Fiber Optic Association Guide To Fiber Broadband Is A Hit With Broadband Planners Paperback ($12.95) and Kindle ($9.95) versions available from Amazon or most booksellers. Kindle version is in color!

New In The FOA Guide - Introduction To Broadband and Guidelines For Fiber Optic Project Planners

Cross Reference Guide to Textbooks, Online Guide and Fiber U FOA Videos Guide.

FOA has a web page with resources on fiber broadband and the IIJA/BEAD funding programs.

FOA Newsletter

Sections

News

Technical

Worth

Reading Q&A

Training/FiberU

Resoures

Safety About

|

|

News

Lots more news

in Worth Reading below

|

Quote of the month: "In today's digital

world, access to technology and the Internet enables boundless

opportunities. Now more than ever, women and girls are seizing

these opportunities to smash barriers and soar to new heights."

Maci Morin and Michell Morton, Office of Internet Connectivity and Growth, NTIA, celebrating Internatinal Women's Day.

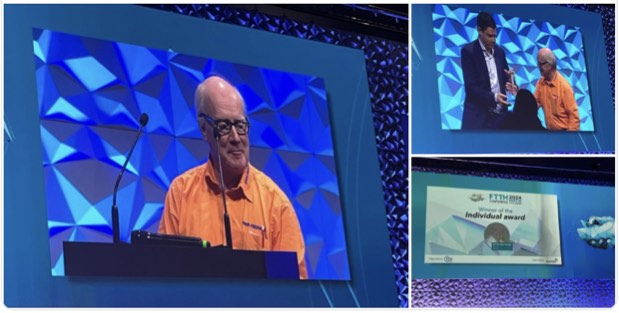

FOA Instructor And Technical Advisor Ian Gordon Fudge of FiberDK

Chosen For FTTH Individual Award In Europe

Ian Gordon Fudge of FiberDK awarded FTTH Individual Award

The FTTH Council Europe recently announced the winners of the

prestigious FTTH Awards and brand-new FTTH Innovation Awards, presented

for the first time at the FTTH Conference 2024 in Berlin. Three awards

in total were presented by Raf Meersman – President of the FTTH Council

Europe, during the plenary session of the FTTH Conference on March 20th,

rewarding the outstanding contributions to the growth of the industry

and the acceleration of FTTH deployment in Europe:

• Prysmian is the winner of the Champion of Diversity Award, for their

unwavering commitment to addressing diversity issues within the fibre

industry

• Ian Gordon Fudge, Owner of Fiberdl is the winner of the FTTH

Individual Award, for his remarkable efforts in championing the

advancement of FTTH technology in Europe

• Open Fiber is the winner of the FTTH Operator Award, for its

exceptional contribution to the development and widespread

implementation of FTTH

"The FTTH Awards celebrate innovation, perseverance, and excellence in

fibre optic. As we honor the pioneers shaping our digital future, let us

reaffirm our commitment to building a connected Europe where

opportunities abound and communities thrive thanks to full-fibre

connectivity," commented Raf Meersman, President of the FTTH Council

Europe."

FTTH Council Europe.

FOA CFOTs Are Everywhere

Climbing Mt. Fuji In Japan

Recently, Tom Collins, a FOA Board Member and Donna Collins, a FOA

instructor, took a fantastic vacation in Japan. On a tour to Mt. Fuji

they met an interesting young man. They struck up a lively conversation.

We found out he had been a Network Engineer in the Philippines and

recently left a job in Japan as a teacher. Currently, he is a travel

blogger in Japan and also provides some tours. During our conversation, I

mentioned to him I belonged to an incredible organization that proves

Fiber Optic instructional materials. He informed us he received the

Certified Fiber Optic Technician certification while in the Philippines.

He showed us his credentials and our jaws dropped! We let him know Tom

was on the FOA Board.

We continued to talk on and off throughout the tour about his career

goals. He told us that Covid-19 put things on hold for him. His

certification recently expired and wanted to know if we could do

anything for him. We offered him a scholarship to complete the Certified

Finer Optic Specialist Design certification and would be more than glad

to help him out.

We were truly blessed to meet him as he helped us out at the train

stations for the Bullet Train ride which concluded our Mt. Fuji tour.

The last stop was at the Tokyo Train Station. We were like deer caught

in the headlights! Luckily, he guided us all the way to the taxi stand.

Getting Trained And Certified In Hyderabad, India

FTTH

AND SMART TECHNOLOGIES in Hyderabad, India recently conducted a class

for CFOT. Ahmed Askar Jaffer Ali completed the class for CFOT

certification. Shaik Kareem, the instructor (right) , presents him with

his CFOT Class Certificate.

New Technical Book On FTTx In Serbian

Vladimir Grozdanovic is a graduate electrical

engineer for

telecommunications with more than 10 years of experience in access

networks (HFC and FTTH) in large cable operators in Serbia (SBB and

Jotel). He has been writing technical articles for the FOA Newsletter

based on his personal experiences. Now he has applied his writing

talents to a textbook on FTTx in his native language, Serbian.

Below is his description of the book (in English!)

The

rapid expansion of the Internet, followed by the introduction of a

greater number of various services, has led to the increased user

demands, which resulted in continuous development of access networks.

Over the past decade, the demand for high bandwidth, high bit

rates in both directions, low latency, and more reliable services have

significantly pushed out old traditional telephone and cable networks

and contributed to the development and widespread popularity of optical

fixed access networks - particularly FTTH (Fiber To The Home).

This book will introduce you to modern FTTx optical networks

and provide a range of practical tips on designing, building, and

maintaining them.

The first part of the book covers the basics of optical

communication systems, types and structure of optical fibres and cables,

followed by fibre and cable labelling conventions, attenuation and

dispersion calculations, and finally measurements performed on optical

networks. The second part is dedicated to FTTx optical networks -

various FTTx scenarios, principles of design and construction, FTTx

testing, and troubleshooting typical problems on FTTx networks.

The book can be ordered through the publisher Infoelektronika website https://www.infoelektronika.net/. Delivery is available to all countries worldwide via standard mail or international express mail EMS.

Broadband Communities Summit 2024

Broadband Communities Summit 2024 is an event for those

interested in delivering connectivity for communities in the US. This

year’s event will bring together 1500 senior-level attendees from the US

broadband sector, municipalities, property owners and government. May

6th – 8th 2024 at The Woodlands Waterway Marriott Hotel & Convention

Center, Texas

Learn more about the Broadband Communities Summit

NEW: Broadband Communities and Total Telecom will also hold Broadband Communities Summit West which will take place at the San Diego Convention Center in San Diego, CA on October 30-31 2024.

Quote Of The Month:

(several months ago actually, but this is worth repeating)

Speaking at the Goldman Sachs Communacopia +

Technology Conference, AT&T’s CEO John Stankey said, “There’s a

fallacy to say there’s fixed networks and wireless networks. There are

only fiber networks with different access technologies on the end of

them. That’s where this is all going.”

Fierce Wireless

|

Technical

Fiber optic

technology, standards, equipment, installation,

etc.

The FOA

Update Page covers the new technology

and applications we covered in this newsletter

recently. Now you can review all that new tech at

once.

Cross Reference To FOA Technical Reference Materials

The FOA has almost 1,000 pages of technical information on the FOA Guide,

100+ videos and two dozen online courses at Fiber U, all this can make

it difficult to find the right information.

Cross Reference To FOA Tech Materials

To help this, we have created a cross reference guide to the textbooks,

Online Guide and Fiber U courses, all the FOA technical information.

Besides the textbooks, online Guide and Fiber U, each section of the

Guide also includes links to the 100+ FOA videos available.

Cross Reference Guide to Textbooks, Online Guide and Fiber U

FOA Videos

We have also rearranged the 100+ FOA videos in similar categories on the

Contents Page of the Online Guide, making the videos, especially the

lectures, much it much easier to find a video on a particular

topic.

FOA Videos Guide.

Want to know more about fiber optics? Study

for FOA certifications? Free

Self-Study Programs are on Fiber

U®

|

OptConn

is a value-add re-seller of optical connectivity products, services and

solutions. With over 30 years of experience in the fiber optics

industry we are here to serve your requirements from fiber optic

training with FOA certification to products, materials and supplies. OptConn

is a value-add re-seller of optical connectivity products, services and

solutions. With over 30 years of experience in the fiber optics

industry we are here to serve your requirements from fiber optic

training with FOA certification to products, materials and supplies.

We have partnerships with industry leading

manufacturers to support your installation, splicing and testing needs.

Our goal is to guide, support and recognized our client’s requirements.

Learn more about OptConn

|

Introduction to GIS and Fiber Management Systems?

There is a rising demand for efficient fiber optic

network solutions, and Jerry Morla has written an article offers an

overview of digital management tools, including emerging options and

traditional platforms. These tools are essential for planning,

implementing, and maintaining networks, ensuring operational efficiency

and customer satisfaction in the telecommunications and fiber optics

sectors. If you need more information in this area, check out the

following article:

While Geographic Information Systems (GIS), Fiber Network Management

Systems (FNMS), and Operational Support Systems/Business Support Systems

(OSS/BSS) each serve distinct purposes, their integrated functionality

enables efficient, reliable, and customer-focused fiber optic network

deployment and operations. Understanding their roles, differences, and

synergies provides a comprehensive view of the technological

orchestration behind the scenes of our interconnected world.

Read the article here in the FOA Guide.

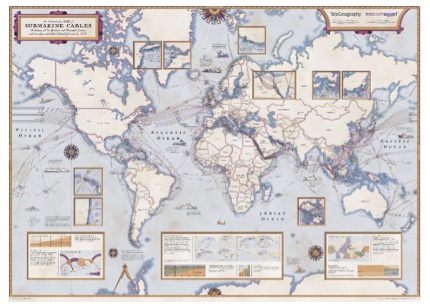

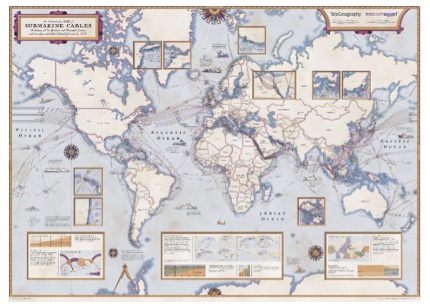

Fiber To The Shore - Not All Submarine Cables Are Transoceanic

There are only a handful of companies that design, build and install

transoceanic cables but they seem to get most of the attention. But

smaller companies like Baylink Networks of Port Coquitlam, British

Columbia, Canada also provide similar services but on a smaller scale.

Here is how they describe their work:

Baylinks builds full turnkey undersea fiber networks connecting

communities. Baylink Networks’ undersea fiber optic cable system is

optimized for rugged undersea environments with minimal impact.

Building land-based fiber optic networks are extremely costly in

comparison to building networks undersea. Unfortunately, traditional

undersea cable methods are unable to offer these economical solutions.

Baylink Networks introduced practical innovations in the undersea

telecommunication space. The compact patented cable system is

rapidly deployed using smaller vessels. Baylink Networks’ patented

cable designs offer unmatched performance in the undersea environment.

Baylink Networks’ product line and methodology are optimized for

building economical regional undersea links connecting coastal urban

centers, remote communities and offshore industry and research.

Learn more about Baylink Networks.

Another Candidate For Best Example Of Worst Install

Woodstock GA, corner of Jamerson Rd and Trickum Rd, NE corner

Contributed by Eric Pearson of Pearson Technologies. Eric is FOA School #101 - the second FOA Approved School.

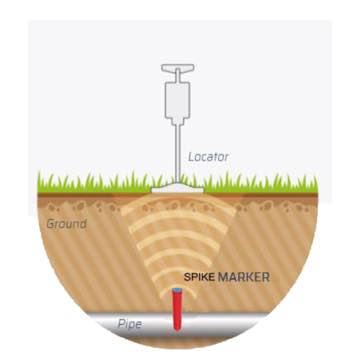

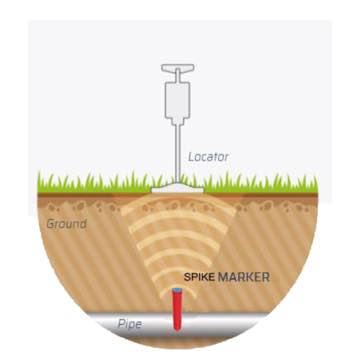

Tempo Spike Markers For Underground Cables

Tempo's new Spike Markers simplify marking items up

to 1 meter (3.3 ft) deep in soil. Their compact design make them ideal

for cable TV drops, fiber, and power/gas lines, and they excel in narrow

ducts. With durable polyethylene construction, they ensure longevity,

while remaining compatible with all locators. The Spike Marker contains

no batteries or active components, and is built using high reliability,

long life materials ensuring these markers last as long as your buried

plant. markers are available in colors to identify the type of

underground utility it marks.

More about Tempo Spike Markers.

NECA/FOA 301 fiber optic installation standard

withdrawn

The NECA/FOA 301 fiber optic installation standard has been

withdrawn. It's almost a quarter century old and a decade since the

last update. It has been decided the standard needs to be replaced with a

more modern document covering current technology and written in a

format that allows easier updating. The NECA/FOA 301 fiber optic installation standard has been

withdrawn. It's almost a quarter century old and a decade since the

last update. It has been decided the standard needs to be replaced with a

more modern document covering current technology and written in a

format that allows easier updating.

In the meantime, there is lots of useful information in the standard and you can still download a free copy from FOA.

Download your free copy of ANSI/NECA/FOA-301

here (PDF)

FTTH Technical Papers

FOA contributor Vladimir Grozdanovic has created

another technical paper on testing FTTH PON based on his field experiences.

Testing The FTTH PON Network (new)

Troubleshooting PON Installations.

Installation of FTTH Active Equipment in the FOA Guide.

Optical Splitters in the FOA Guide.

Examples of poor installation of FTTH in the aerial outside plant and in the customer premises.

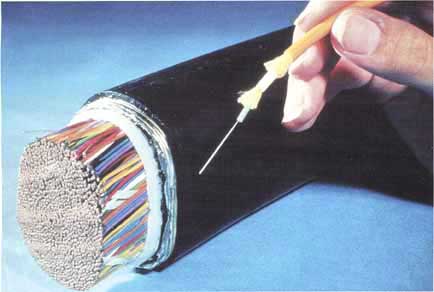

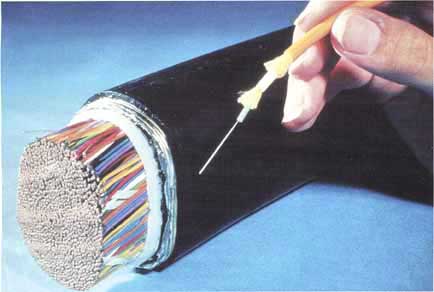

Learning Important Information From A Found Cable Scrap

While walking down the street near the FOA office, we found this cable

laying in the gutter. What a find! A short length of Corning Rocket

Ribbon 864 fiber cable left over from an installation by a contractor.

We brought the cable back to our office with the intention of opening it

up and creating a video about the construction of this modern high

fiber count cable, but something got our attention first. The cable had a

very

long line of printing on it with lots of interesting and useful

information. So before we started deconstructing it, we decided to

photograph the printed information and interpret it. That turned out to

be an important part of the information we learned from the cable. Then,

as you will see below, we dissected the cable and learned even more.

Red more about what this cable marking tells you and what the cable looks like when you open it up to prepare for splicing.

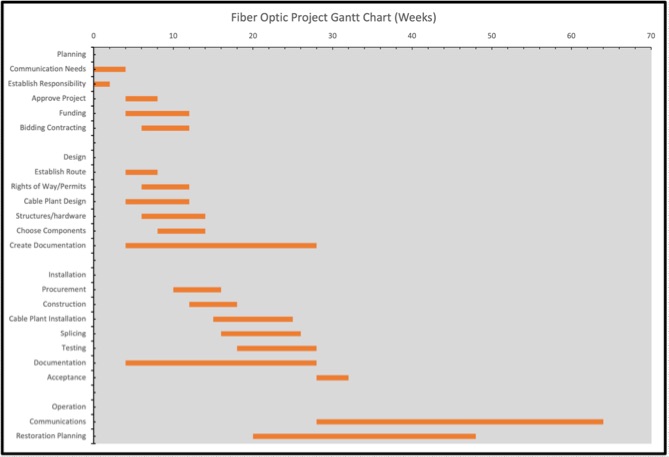

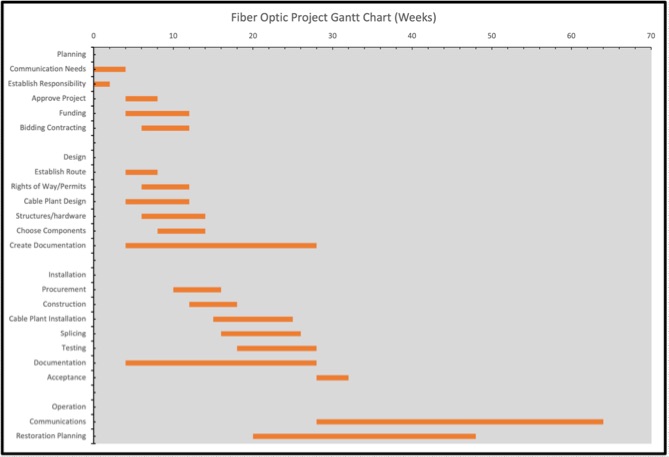

Managing Fiber Optic Projects - The Gantt Chart

(With An Excel File To Make Your Own)

The most common way to track projects is the Gantt Chart, a

chart of activities that tracks the progress of projects along a

timeline. each activity is represented by a bar and the position and

length of the bar represents the starting date and duration of the

activity. This allows you to see what activities are needed for the

project, when the activities start and end so it can be used to track

the progress of the project visually. Here is what a Gantt Chart for a

fiber project might look like:

You might remember an article in the FOA Newsletter in April 2022 or the FOA Guide page on Project Management about the timing of a fiber optic project where we showed the progression of steps in a project like this: You might remember an article in the FOA Newsletter in April 2022 or the FOA Guide page on Project Management about the timing of a fiber optic project where we showed the progression of steps in a project like this:

The Gantt Chart is simply this list converted to a Gantt Chart

using a Microsoft Excel spreadsheet. You can download a copy of the FOA Gantt Chart spreadsheet (xlsx file - 16kB)

and use it to create your own Gantt Chart for any project. All you have

to do is to input your own data and change the activity names as

necessary. You can also follow the directions from Microsoft to create your own version.

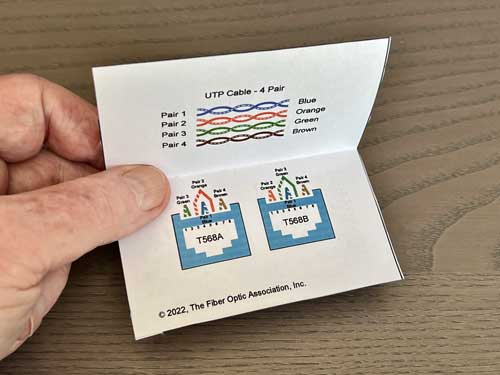

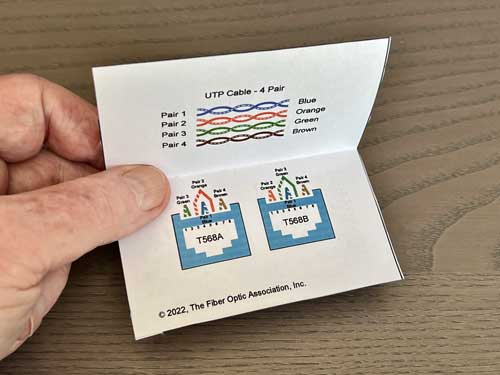

Help On Color Codes (Including Copper Cabling And Fiber Optics)

The FOA has created a print-your-own pocket guide to fiber

optic color codes. It has

color codes for fibers and buffer tubes, connectors and premises cables

inside and on the back, QR codes to take you directly to the FOA Guide

and Fiber U. The FOA

Guide page on Fiber Optic Color Codes is one of the most read pages on the FOA

website and the Fiber Optic Color Codes minicourse on Fiber U very popular also.

Here are the links to download your own FOA Guides to Fiber Optic Color Codes

FOA Guide to Fiber Optic Color Codes (print your own version) PDF

FOA Guide to Fiber Optic Color Codes (electronic version for your smartphone, tablet or PC) PDF

And Color Codes For UTP Cabling

FOA Guide to UTP Cabling Color Codes (print your own version) PDF

FOA Guide to UTP Copper Cabling Color Codes (electronic version) PDF

Warning For Techs Doing OSP Restoration

FOA received an inquiry about whether techs

working on restoring OSP links should be concerned about eye safety if

the link used fiber amplifiers. To answer this question, we had to do some research on fiber amplifiers.

The short answer is YES, you should be concerned. The long answer is

more technical and includes details that every OSP tech needs to know. FOA received an inquiry about whether techs

working on restoring OSP links should be concerned about eye safety if

the link used fiber amplifiers. To answer this question, we had to do some research on fiber amplifiers.

The short answer is YES, you should be concerned. The long answer is

more technical and includes details that every OSP tech needs to know.

See "Fiber Amps And Restoration" in the FOA Newsletter Archives..

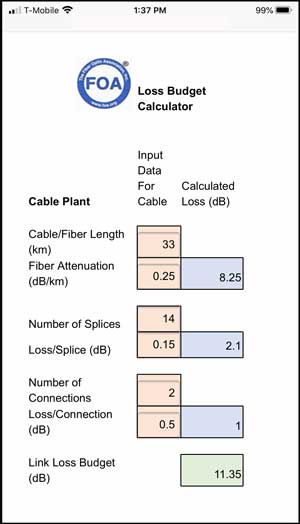

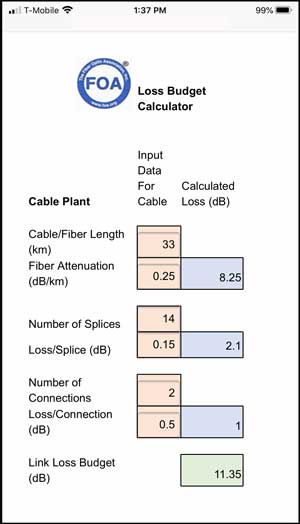

Try The FOA's Online

Loss Budget Calculator

FOA

has written many articles about loss budgets,

something everyone involved in fiber optics needs to

know and needs to know how to calculate. We've

created a online Loss Budget Calculator that does

the work for you. Just input your cable plant data

and it calculates the loss budget. It works on any

device, especially smartphones and tablets for field

use and even allows printing the results.

Bookmark

this page (especially on your smartphone): FOA Loss Budget Calculator

Online

|

Worth Reading

Each month we read

hundreds of newsletters and online articles. These

are the ones we think you will find "worth

reading."

FOA has a web page with resources on fiber broadband networks and the IIJA/BEAD funding programs.

Cross Reference Guide to FOA Textbooks, Online Guide and Fiber U

AT&T PR photo from the mid 1970s AT&T PR photo from the mid 1970s

The FOA's History

Stories From The Past FOA Newsletters

Recent articles from The FOA Newsletter

Fake OTDR Traces Submitted For Testing Documentation January 2023 Tech

Using OTDRs To Test Transoceanic Cables And PONs February 2023

POF - the Other Fiber March 2023

What Do Employers Expect From A Fiber Optic Tech? April 2023

Are Standards Ignoring The OSP? May 2023

FOA Has Proven Results In Fiber Optic Workforce Development June 2023

BEAD Funding For States Announced And Analyzed July 2023

Wisdom From The Street (Analyzing the printing on a fiber optic cable) July 2023

Focus On Disasters August 2023

FOA's Role In Education and Work Done By Fiber Techs September 2023

The Workforce: New US DoL Bureau of Labor Statistics Telecom Tech Category October 2023

How Many Telecom Techs Do We Need and How Big Is The Fiber Optic Market November 2023

Guidelines For Fiber Optic Project Planners December 2023

2023 Year In Review. Kentucky Shows The Value Of Fiber January 2024.

What is Broadband? History of the Cable Modem February 2024

It's Just Economics. Things you need to know. March 2024.

|

Worth Reading (And

Watching):

March 2024

Can Our Industry Develop Fiber Talent? ISE Magazine. Learn how states, schools and training organizations must work together to develop fiber field talent.

Landlines are dying out. But to some, they’re a lifeline. Washington Post Providers want to scale back landline service, but people with poor cell reception still rely on it for emergencies.

What’s Ahead for Fiber-Optic Markets and Technologies? CI&M Magazine Video. Interview

with AFL’s vice president of market strategy and innovation Seán Adam

talking about 2024 and the future. Hint - broadband is not the biggest

driver of the fiber optic market!

Can Xerox’s PARC, a Silicon Valley Icon, Find New Life with SRI? NYTimes. Xerox's

Palo ALto Research Lab was the innovative lab that created laser

printers, the graphic user interface and mouse for PCs and Ethernet.

Xerox just gave it to Stanford Research Insitute. What will happen?

Choice Broadband and Tarana Partner to Narrow Navajo Nation’s Digital Divide. Tarana Wireless. Discusses new developments in wireless for rural areas.

February 2024

The Jan/Feb Issue of ISE Magazine is online. Includes a review of the telecom year and Is it Time to Update Your Gear for the New Year?

The State of the Network in 2024 from Telegeography.

Las Vegas residents will soon have a new option for internet service: Google Fiber from KTNV TV Las Vegas

Network resiliency for an open networking future from Infinera (the topic is network backups and restoration.

Recent Articles

Pre-Excavation Safety Checklist (PDF) - Excavation Safety Alliance - essential steps before breaking ground for underground construction.

Fiber vs Wireless - Are You Kidding? ISE Magazine Of course we need both!

Developing a Fiber Workforce Really Does Take A Village - ISE magazine looks at the role of manufacturers' training in developing the fiber workforce.

How Many More Fiber Techs Do We Really Need? - ISE Magazine

Telegeography Submarine Cable Map 2023 - You can also buy copies - Telegeography

CABL® (cabl.com) serves

the business needs of the Broadband industry (including traditional

cable TV, fiber, telecom and satellite providers) with employment

listings, classified ads, discussion forums, and more. A contractor told us it's where they find lots of opportunities for subcontracting.

Do You Believe In Magic? Sufficiently advanced technology is indistinguishable from magic. ISE Magazine.

The Secret to Future Proofing, ISE Magazine

The 45 Year Old Overnight Sensation - ISE Magazine (Read the complete Nov/Dec issue of ISE Magazine here.

ESRI has created an ebook on GIS location technology for telecom. Use the link to download the book.

Conocimiento Esencial: ¿Por qué la fibra óptica? creado por FiberWizards

Recruiting And Training Today's Fiber Optic Workforce - Learn the fundamentals to recruit and train new fiber optics -ISE Magazine.

Google Video On Their Undersea Cables YouTube Slick but interesting video on how undersea cables are designed, built and used.

Construction Without Disruption - ISE Magazine

Fiber Optics Installed By The Lowest Bidder - ISE Magazine

Building Broadband During Component and Worker Shortages

- Broadband Communities - Completing broadband builds requires

competent fiber optic techs, but training them requires understanding

how they learn.

Worth Reading - Magazines, Websites and Newsletters

CABL® (cabl.com) serves

the business needs of the Broadband industry (including traditional

cable TV, fiber, telecom and satellite providers) with employment

listings, classified ads, discussion forums, and more. A contractor told us it's where they find lots of opportunities for subcontracting.

The Institute for Local

Self-Reliance weekly newsletter has

lots of interesting articles and links.

Next Century Cities Newsletter

- News from cities around the US

including Detroit and New York plus small

Structured Cabling News

- a website and weekly newsletter about cabling.

New Fiber Optic

Magazine In Spanish

We do not know about the fate of Todo Fibra Optica following the passing of Jose.

Todo Fibra Optica is

a new digital magazine in Spanish for fiber optics

in Latin America and South America. Jose Enriquez, editor of Todo

Fibra Optic magazine has many years

experience in the fiber optic industry so he knows

the industry well. FOA will be working with him to

share our extensive technical materials in Spanish.

Read their newsletter here. It is now available online in English and Spanish.

Read their newsletter here. It is now available online in English and Spanish.

All issues and subscriptions.

Contact:

José Manuel Enriquez Mora, Editor

Todo Fibra Optica LLC

https://todofibraoptica.com/revista-ediciones/

+52 222 302 8224

jose.enriquez@todofibraoptica.com

RTI Telecom Magazine from Brazil, in Portuguese. A revista RTI do mês de abril já está disponível online e recomendo a leitura de alguns artigos:

FOA was founded in 1995 - FOA's History

As

part of celebrating 25 years of serving the fiber

optic industry in 2020 as its primary source of technical

information and independent certifying body, FOA

thought it appropriate to create a short history of

the organization and how it has developed to

help the fiber optic industry. We also wanted to

recognize the contributions many people have made to

the organization over the years that made FOA what

it is today.

The FOA history is now archived on the FOA

website where you can read it anytime or link to

it. Updated

info - dB, total internal reflection and science

projects,

Worth Reading - History & Technical

1983

Video of AT&T's First Test Of A Submarine

Cable System From the AT&T Tech

Channel archives (worth exploring!)

Richard

Epworth's Optical Fiber History from his work

at STL from 1966 with Charles Kao.

50th Anniversary of The

Development of Low Loss Fibers A history

of the development of low loss fiber, a fascinating

story by Jeff Hecht on the OSA (Optical Society of

America) website.

The First Transcontinental Telephone Line

began operation on July 29th in 1915 - 3400 miles between New

York and San Francisco - required over 100,000 telephone poles! Wonders

of World Engineering

"Who Lost Lucent?: The

Decline of America's Telecom Equipment Industry"

This is a MUST READ for managers in telecom or any

industry!

Communications Systems Grounding

Rules: Article 800 provides specific

requirements by

Michael

Johnston, NECA Executive Director of

Standards and Safety in EC Magazine

US Broadband Coverage By Service

Provider from the FCC

How

To Build Rural Broadband, Learning From History

In the August 2021

FOA Newsletter, we published a lengthy article on

rural broadband and compared it to rural

electrification in America in the last century.

Much of the comparison was based on an article

written in 1940 by a USDA economist, Robert Beall,

called "Rural Electrification." If

you are interested in or involved in rural

broadband, we recommend you read the article "How

To Build Rural Broadband, Learning From History"

in the August 2021 FOA Newsletter and

read the Beall article also.

Recycling Fiber Optic

Cable - Contact:

Steve Maginnis

LD4Recycle/ CommuniCom Recycling

(Visit

website)

sm@LD4Recycle.com

803.371.5436

Sumitomo's Ribbon

Splicing Guide - download from

one of the leaders in splicing.

OFS also has an excellent

website and blog of tech articles worth browsing.

IEC 60050 - International

Electrotechnical Vocabulary - An

extensive dictionary for fiber optics in English and

French. Highly technical - this is one definition:

"mode - one solution of Maxwell's equations,

representing an electromagnetic field in a certain

space domain and belonging to a family of

independent solutions defined by specified boundary

conditions"

Restoration: If you are interested in restoration -

aren't we all? - you should also read this

article in dpPro magazine by FOA President Jim

Hayes: Damage Protection Requires

Looking Overhead As Well As Underground

- dpPRO Magazine - about the problems with

aerial cables. His previous article for the

magazine was New Techniques for Fiber

Optic Installation.

Universal access to broadband

is a cornerstone to a strong economy,

Achieving universal access will require

community partnerships. by Alfreda

B. Norman, Sr. VP, Federal Reserve Bank of

Dallas

FIBER TO THE FARM: The

co-ops that electrified Depression-era farms are

now building rural internet. Be sure to check out

the high-tech equine installation equipment.

Infrastructure Get Some

Respect, NY TImes "On Tech"

"The magic of the internet requires a lot of

very boring stuff behind the scenes. "

DIRT

Report On Damage To Utilities Common Ground

Alliance (CGA) annual DIRT report provides a

summary and analysis of the events submitted into

CGA’s Damage Information Reporting Tool (DIRT) for

the year 2018. The complete report is available

for download here. In addition,

there is an interactive dashboard that

allows users to filter the data more by

factors contributing to damages.

Fiber Trivia From

Corning.

VIAVI Books On

Fiber Optic Testing (2 volumes) - They're back!

Besides

the FOA reference materials, two JDSU/VIAVI

textbooks, Reference Guide to Fiber Optic Testing,

Volumes 1 and 2, were used as references for

some of the FOA courses and are recommended for

instructors and students. The books are available

from VIAVI as eBooks and the everyone should

download them and recommend them to others.Download

yours now. Volume 1. Volume 2. Viavi Books

Ciena's Submarine Cable

Handbooks (4 to download)

How OFS Makes Fiber

Interesting YouTube video on how fiber is made.

Perhaps a little too much "show biz" but

fascinating. If you have ever seen fiber

manufacture, look at this video. You will be amazed

at how big preforms have become!

The True Cost of Telco Damages

(what backhoe fade or target practice can

cost)

Rural Electric Cooperatives:

Pole Attachment Policies and Issues, June 2019.

|

Q&A

When readers ask us questions, we genrally refer them to FOA

resources where they can find the answer to their question and many

more. We first send them to the FOA Guide

which is the table of contents for the FOA technical resources. There

they can find pages indexed by topic and a search engine for the FOA

website. It also links them to FOA videos and courses on our free online learning site Fiber U.

The FOA

Fiber FAQs Page (FAQs = frequently asked

questions) gathers up questions readers have

asked us (which first ran in this newsletter)

and adds tech topics of general interest.

|

Good Question!

Tech

Questions/Comments From FOA Newsletter Readers

Color Code Guides

Q: Is it possible for you to please send me a fiber optic color code bundle pocket size?

A: FOA has color code guides you can print yourself or download to your smartphone or tablet.

See https://foa.org/tech/ColCodes.htm

What's included in a government grant?

Q: When a companyb is awarded a 'government grant' to

install fiber in a given area, does the 'grant' money also include the

splicing, testing, etc; is it dark or lit?How about providing the

transmission of actual broadband services to a home or business?

A: What is included in grants depends on the project

submission. A "middle mile" project could include the fiber optic cable

plant with drops for users to connect to dark fibers or be a complete

communication system with carrier Ethernet service points to users to

connect. In either case, it includes all the construction, cable plant

installation and testing.

A communications system proposal could also include connecting users if

the originator of the proposal knew the number of users to be connected

-each one of which adds costs. Same for a FTTH network. It could just be

the cable plant, a functioning PON system with drops available to all

users passed or include connecting users. One could do an educated guess

on the percentage of homes passed that would connect, or include a user

paid connection fee to cover the costs.

It depends on the proposal that was submitted and approved.

How to handle results from OTDR measurements

Q: The discussion evolves around how to handle results from OTDR measurements.

The cable manufacturer wants to average the results of a splice event

from a set of bi-directional OTDR measurements. Essentially, the

cable manufacturer wants to average the loss measurements from the

bi-directional measurements. In specific, we have an event (that

we think is a splice) that has a loss in one direction and a reflection

in the other direction

A: The issue of bidirectional OTDR measurements is covered in the FOA Guide: https://foa.org/tech/ref/testing/OTDR/OTDR.html

Wavelengths

Q: What is different between 1310 nm and 1550nm

A: Those are the two wavelengths used with singlemode fiber.

They are used because they were two wavelengths that the fiber would be

singlemode (>1270nm) and wavelengths that it was easy to make solid

state lasers 40 years ago when they were introduced. Longer

wavelengths like 1550nm have lower loss in the fibers so the

fibers for very long distance links are optimized for 1550nm

Mating Mismatched Connectors

Q: I have a question during OTDR Testing... The interface

port of the OTDR is SC-APC so i have also a launch cable with SC-APC

connectors, end to end. the fiber cable plant that i need to test has a

patch panel connector of LC-UPC.. can i use a hybrid adapter to connect

my launch cable to the patch panel? if this is allowed, what will be the

formula for calculating the connector loss.. note: the adapter has an

insertion loss of <0.3dB

A: You need to use a hybrid adapter cable with a LC/UPC

connector on one end to connect to the cable plant under test and a

connector to connect to your usual launch cable - and that cable needs

to be longer than the dead zone of the OTDR so the connection to the

cable plant can be separated and not affected by the connection on the

other end to your normal launch cable. Alternatively, you can have a

hybrid launch cable with SC/APC on the OTDR end and LC/UPC on the cable

plant end.

You cannot use a hybrid mating adapter. The angled SC/APC connector

cannot be mated to a UPC connector. Anyway th ehybrid SCLC mating

adapters are not a good idea becasue of the difference in the diameter

of the ferrules.

OLTS or OTDR?

Q: A client is requesting a certification according to ISO/IEC

11801, ISO/IEC 14763-3, TIA- 526.7-A, TIA-568.3-D, ANSI/TIA 568 C.3 or

later. I own a single-mode OTDR and a power meter with a Microscope. If I take

measurements with all three units and calculate the maximum allowable

drop according to length and given connectors or splicing to give

results on a pass or fail will be adequate or we have to measure with an

OLTS?

A: There is a task force in TIA TR42.11 trying to rationalize these

standards. Today most standards require testing with a light source and

power meter (LSPM) or optical loss test set (OLTS) which are the same

thing as the accepted method for testing an installed cable plant.

Several international standards now allow OTDR testing for acceptance,

but not in any TIA or US standards. So one should assume OTDR tests are

not acceptable, only OLTS testing.

FTTH Network Loss

Q: What are the causes of high loss in FTTH

A: The loss can be connections, including dirty connections, bad

splices, damaged cables, even a bad splitter. Have you tested with a

high resolution OTDR?

GIS Programs

Q: Have you done any reviews on OSP fiber route-structure mapping

systems and the associated GIS, or do you have opinions on the best

ones/combinations (Esri, 3GIS, Bentley, Graphical Networks, Vetro,

etc.)? Or can you point me somewhere to go read, search doesn't come up

with a lot of details.

A: Among the most established ones here in US are ArcGIS, IQGeo,

3-GIS, Vetro and OZmap. All seem to have proponents but we do not have

much practical experience except one of the FOA Tech Advisors uses OZ

map.

Older Questions:

Fiber Loss Budget

Q: For a fibre of total distance of 160km, what should be the standard total loss per kilometre?

A: The typical loss for SM fiber is ~0.35-0.4 dB/km at 1310 nm or

~0.15-0.2 dB/km at 1550. We assume a system like this will be using

1550 nm. You can use the FOA online Loss budget Calculator

https://foa.org/tech/ref/Loss_Budget/Loss_Budget.htm to estimate the

total link loss

Reuse Of Cable Being Removed From Service

Q: Is there ever a feasible reuse for used/older fiber optic cable?

Would some one be in the market for the FOC that is removed from

service? Lets say 20year old aerial cable ADSS?

A: We have been asked that question a lot. It often involves cheap

fiber on eBay or from surplus dealers. With the advances in fiber

technology and manufacturing, 20 or even 10-year old fiber is

essentially obsolete. Lots of service providers are replacing that fiber

with today’s higher performance fibers because networks are going from

the ~2 gigabit speeds then to terabit speeds today. We would never

recommend reusing fiber removed from service. You have no knowledge of

how it was installed originally and environmental conditions can be hard

on some types of cables. Besides, the cost of the cable is only 5-15%

of the project cost. Most of the cost is in the labor of installation so

the savings would be minimal and the risk high.

We have been telling people who have leftover cable from projects to

offer it to FOA schools. They are always in need of OSP cables.

Minimizing Latency

Q: Latency a term that is widely used today. If we manage to

make the light travel without interruption we will achieve that the

speed is perfect, but the equipment (router, OLT, firewall, etc)

generates a processing that takes some time, do you think that LATENCY 0

will be achieved?

A: The work on achieving minimal latency has been gong on for

decades, primarily driven by the computerized stock traders who rely on

microsecond trading. One recent project used an experimental fiber with a

hollow core becasue light travels 50% faster in the air than glass.

Most low latency networks try to use the longest fiber links possible

using submarine cable technology because the electronic switching takes

too much time. But most electronics require digital signal processing in

the transceivers which takes time, switches to the trading computers

takes time and while you can minimize it all, it can never reach “0”.

Microtrenching

Q: What is microtrenching?

A: Microtrenching is a technique for installing underground

fiber. It is done by sawing a groove in the road or sidewalk and

dropping a small (~1/2 inch or 13mm) plastic tube (duct) into the

groove and filling it up with material like the surface so it almost

disappears. The cable is “blown” into the duct with high pressure air -

actually the air floats the cable in the duct to reduce friction and the

cable is pushed into the duct.

Here are photos of a microtrenching installation in Toronto. Here is the explanation of microtrenching in the FOA Guide section on OSP Construction (about 3/4 down the page.)

We don’t think any of our schools teach this in the US but Triple Play does in South Africa.

In the US we recommend going to one of the companies that makes the construction equipment, primarily Ditch Witch.

Degraded Underground Fiber Optic Cable

Q: How can you handle a degraded buried

underground fiber link, which has degraded due to multiple joints

introduced during maintenance?

A: If it has reached a point where the loss or dispersion limits its use, it probably should be replaced.

Maintaining Fusion Splicers

Q: What are the best practices for the preventative maintenance of splicers, cleavers, and thermal strippers.

A: Because of the large number of manufacturers and variety of

models and applications, The FOA generally tells people to follow the

manufacturer’s directions for use and be especially careful about

keeping the splicer unit, cleaver and stripping tools clean, then having

it serviced regularly by the manufacturer or an authorized service

facility.

Rural FTTH

Q: What does A Rural FTTH Connection Cost?

A: That's a very complicated question, because "rural" has a lot

of meanings. Is it a small town where building a FTTH Network is easy or

remote users in Alaska? An interesting set of data was made available

this month from the US Department of Agriculture, announcing $700

million in grants and loans in the 4th round of the ReConnect Program https://lnkd.in/gFe9T4b7.

Splicing Dissimilar FIbers

Q: Recently I came across a new problem while splicing optical fiber

cable. Splicing of 2 Fujikura fibers was done but loss was

observed. Initially, we felt that it is due to splicing but upon

resplicing the loss was still the same i.e. 0.3db at the splice point.

Both the cables were checked again and observed that both cables were

from different manufacturers. My question is that if different

manufacturer's cables are spliced, will it give loss? Note: Both fibers

were Fujikura but had different IOR.

A: The difference in IOR tells the reason. The loss at the joint

between the two fibers when measured by an OTDR depends on the optical

characteristics of the fibers. A difference in the fibers IOR and

backscatter coefficient will cause the loss measurement to be affected.

In one direction it measures too high, in the other direction too low or

even shows a gain. That’s why some measwurements are called gainers. If

you measure it in the opposite direction you should see low loss or a

gain. It’s explained here in the OTDR page on the FOA Guide https://foa.org/tech/ref/testing/OTDR/OTDR.html in the section “OTDR Measurement Uncertainty.”

Testing FTTH Networks

Q: I work on FTTH projects that utilize 1x32 and 1x64 splitters that

do not have any active light on the fibers. Is there a mobile source

that can be used in the field to simulate active light through splitters

and still provide enough power to travel 20km?

A: Any 1310/1490/1550 test source should have adequate power to

test them with a regular power meter. A 64 port splitter has only

18dB+any excess loss- so 20dB or so - and any power meter can measure

that with a ~0dBm to -6dBm source.

More on testing FTTH Networks

OTDR Dead Zone

Q: What is dead zone when using OTDR?

A: The "dead zone" is the length of fiber near the OTDR that is

blanked out by the overload from the test pules. See this page on OTDRs

in the FOA Online Guide: https://foa.org/tech/ref/testing/OTDR/OTDR.html

Using A Visual fault lOcator

Q: What are the best practices for using a VFL to locate fiber faults?

A: See https://foa.org/tech/ref/testing/test/visual.html in the FOA Online Guide

Fiber Splicing Cost

Q: What is the standard of costing for fiber splicing and

terminations? Is it per core / per splice or per each cable end

irrespective of the number of cores?

A: That is a very hard question to answer, other than to say ”it

depends. ” The number of fibers is definitely a factor because each

fiber must be stripped, cleaned, cleaved and spliced then placed in the

splice tray.

It also depends on:

- Single fiber or ribbon splicing?

- Type of splice closure

- Type of cable (loose tube, ribbon, flexible ribbon, high density, armored, ADSS, etc.)

- Installation: aerial or underground

- Location: urban or rural

- Set up time (same for low fiber count cable as high fiber count cable)

Most contracts will be considering the number of

fibers but also these factors, and probably they want to price by the

number of fibers, but the price per splice will vary accordingly. We've

seen quotes in the US for prices varying over a 10X range.

Markers Required For Underground Fiber Optic Cables?

Q: Are signs required for underground cables like fiber

optic cables? Are they required to have signage so people don’t dig them

up or damage them?

A: In the US the answer is NO. There is no Federal or State law

which requires marking anything other than hazardous liquids and gases.

It is purely a business decision or a moral decision to invest in

signs/markers to protect buried fiber. If a fiber gets cut it can

disrupt 911 service and all kinds of vital communication related to

hospitals, air traffic control, etc.

Fiber Optic Color Codes Reference Chart

Q: Has anyone made a fiber optic pocket reference chart that has cable

color orders, frequencies, or other commonly used info on it?

A: The FOA has a page on its Online Guide that covers color codes

(https://foa.org/tech/ColCodes.htm). It is the most popular page in the

FOA Guide! It works great with a smartphone.

The

word on the "Dig Once" program is getting out - FOA

is getting calls from cities asking us for

information and advice. Here are some links:

The DoT page on the administration’s Executive

Order: http://www.fhwa.dot.gov/policy/otps/exeorder.cfm

And the

one to download and hand out:

A “How To” Guide from The Global Connect Initiative:

https://share.america.gov/wp-content/uploads/2016/04/6.-GCI-Dig-Once.pdf

|

Training / FiberU

News and resources to help you learn more and stay

updated.

Learn about the fiber optic/ broadband workforce

Find a

listing of all the FOA-Approved schools here.

Free online

self-study programs on many fiber optics and

cabling topics are available at Fiber U, FOA's

online web-based training website.

Free online training at

Fiber U

The FOA has >100

videos on  |

The Types of Work Done By Fiber Techs And How It Affects Training

What is a fiber optic technician? What kinds of work

do they do? Those topics were the center of FOA discussions with the US

Department of Labor Bureau of Labor Statistics that led to the new job

category of "Telecommunications Technician" on the BLS

website. The focus of this job category is primarily the

installation and operation of the fiber optic cable plant, but one

should not forget the cable plant must be designed also as part of a

more extensive communications network.

In our discussion with the BLS analysts, we pointed out the various

stages of a fiber optic communications network project and how techs

with various knowledge and skill sets are needed and involved in every

step. Here is how FOA defines these stages of a project and the skills

of the techs. This is not unique to FOA; it's what has been traditional

at telecom companies forever.

Planning and Design: Once needs for a communications network is

established, project managers will be responsible for all the details of

the project while experienced fiber techs trained and experienced in

fiber optic network design (CFOS/D) will design the cable plant itself. (FOA Guide - Design)

Construction: Aerial cable plants may require installing new poles or

doing make-ready on existing poles and messengers. Underground

construction requires trenching and installation of ducts. In many cases

the actual construction is done by general construction workers, as the

construction work in many cases is not unique to fiber optics. Heavy

machinery is required for much of the construction work and training is

focused on safety as well as operating the machinery. (FOA Guide - Construction)

Fiber Optic Cable Installers: Once the route is prepared, the fiber

optic cable can be installed. Aerial cable installation depends on the

type of cable. Regular OSP cable, figure 8 cable and ADSS cable requires

special hardware and installation techniques so the techs must

understand the process appropriate for each cable. (FOA Guide - Installation)

Splicers: Since the beginning, fiber techs have been called

"splicers"

because that was the original job unique to fiber optics. Construction

and cable installation was not very different from earlier copper

cables, but splicing was very different. Even today, fiber techs are

often called splicers and splicing is a core skill for any fiber tech

whether they are joining cables or terminating them. (FOA Guide - Splicing)

Testers: After the fiber optic cable is installed and spliced,

it must be tested. Testing goes together with splicing since every

splice will be tested, often as soon as it is made so if it needs

redoing, it should be done before the splice closure is sealed. (FOA Guide - Testing)

Network Operators: Once the cable plant is built and the communications

equipment installed, it needs techs who know how to operate the comms

but may only know how to connect new gear or change connections on

current gear. These techs should also know how to troubleshoot systems

in an outage and either do the restoration themselves or call a tech who

can. (FOA Guide - Operation)

These categories merely define the stages of installation of a fiber

optic project. Of course there are subsets of these categories and most

fiber techs are expected to have skills and jobs that cross into

multiple groups, as FOA has defined in the KSAs (knowledge, skills and abilities) for a CFOT.

What an individual worker does differs according to their job. An

independent fiber contractor may cover every job except

operation and a FTTH subscriber installation tech may only understand

installing cables, testing and connecting equipment within the scope of

FTTH systems. A construction company may handle the trenching and even

pole setting as well as parts of the traditional fiber work.

The FOA defined its role early on to focus on educating and

certifying techs in the fiber specific skills: cable installation,

splicing, testing and restoration. FOA would like to see more schools

get into the construction phase, especially for newer techniques like

microtrenching and blowing cable, but these require large outdoor areas

for training and large investments in equipment. Most techs who learn

these processes now do it with OJT - on-the-job-training - and hopefully get OSHA

training for safety.

New In Spanish - Nuevo en español

FOA Spanish Textbook And Online Guide Updated

The FOA Spanish textbook and Online Guide on basic fiber optics has just

been updated. The new version includes all the latest updates and is

intended for use with FOA CFOT certification classes presented in

Spanish. Both paperback and Kindle versions are available. The textbook and the updated CFOT class

curriculum are available now.

Libro de texto en español y guía en línea de FOA actualizados

Se acaba de actualizar el libro de texto en español y la Guía Online de FOA

sobre fibra óptica básica. La nueva versión incluye las últimas

actualizaciones y está diseñada para usarse con las clases de

certificación FOA CFOT presentadas en español. Están disponibles

versiones de bolsillo y Kindle. El libro de texto y el plan de estudios

actualizado de la clase CFOT ya están disponibles.

FOA Adds Fiber Optic Network Design in Spanish

The FOA Design textbook and course curriculum are available in Spanish also. The FOA CFOS/D curriculum in Spanish includes the necessary materials

for an instructor to present the course in Spanish and give thCFOS/D

certification exam in Spanish. The material is available to any

FOA-approved school. For more infirmation on becoming a FOA approved

school, go here.

El libro de texto de FOA Design y el plan de estudios

del curso también están disponibles en español. El plan de estudios de

FOA CFOS/D en español incluye los materiales necesarios para que un

instructor presente el curso en español y dé el examen de certificación

CFOS/D en español. El material está disponible para cualquier escuela

aprobada por la FOA. Para obtener más confirmación sobre cómo

convertirse en una escuela aprobada por la FOA, vaya aquí.

FOA School News

FOA's roster of approved schools is growing as more organizations

recognize our expertise in workforce development and our comprehensive

support for getting new schools started. FOA has over 25 years

experience and nearly 100,000 certified fiber techs (with ~130,000

certifications). As a non-profit organization founded by the industry

specifically to develop a competent workforce, FOA provides the

consultation, curriculum and contacts to get schools started as a free

service to new schools.

Complete listing of FOA Approved Training Organizations

Need A Fiber Optic Course Onsite? Invite an FOA School To Come To You

FOA often gets inquiries from an organization that

has personnel that needs training in fiber optics. Recent inquiries have

included contractors, a manufacturer of high-reliability products using

fiber optics and a cable manufacturer. In many cases, where there are

several people needing training, FOA can recommend a FOA Approved School

and Certified Instructor who will come to their location to teach a

class. The advantage is of course the savings in travel costs if

the class comes to you, but it also offers the opportunity to customize

the course to fit your needs, even use your equipment or work on your

components, so the training is more relevant to those taking the class.

Contact FOA to discuss the idea of a custom, on-site class to see if it will better meet your needs.

Fiber U

On-The-Job Training (OJT) Program

The

FOA Fiber U OJT program for novices combines online study at

Fiber U with OJT with mentoring by experienced

co-workers and their supervisor to help new employees

develop into experienced FOA-certified technicians.

The FOA Fiber U “OJT-To-Cert”

program includes both fiber optics

and premises cabling (copper, fiber & wireless),

so it covers techs working in both outside plant and

premises jobs.

Like other FOA

programs, the OJT-To-Cert program is free. If you

and/or your company is interested in the FOA

OJT-To-Cert program,

contact FOA.

To explain how OJT

works and FOA's OJT-To-Cert program, FOA created a

short video: Lecture 62: On

The Job Training For Fiber Optics Using Fiber

U

FOA

Direct Certification Program For Experienced Fiber Optic Techs

Experience Plus

Online Study At Fiber U = FOA Certification

Experienced fiber optic technicians can become FOA Certified using

their experience in fiber optics and study for the

FOA certification exams online at Fiber U. Thousands of

industry professionals have applied to the FOA

directly for certification without the need for

classroom training, based on their knowledge and

skills developed working the field. Since FOA

certifications are based on KSAs (knowledge, skills

and abilities), current techs can show the

skills and abilities required through their field

experience. FOA provides free online self-study courses at Fiber U for the knowledge

part to prepare you for FOA certification exams

which you can also take online.

If you are an experienced field tech interested in

certification, and FOA is the internationally

recognized certifying body for fiber optics, you can

find out more about the FOA Direct Certification Program

here.

If you are already a CFOT, FOA also offers many

specialist certifications you can obtain based on

your experience as a field tech. See what's

available at Fiber

U.

Fiber U "Basic Fiber

Optics" Online Self-Study Course Now In Spanish

El curso de

autoaprendizaje en línea "Fibra óptica básica" de

Fiber U ahora en español

El sitio de

aprendizaje en línea de FOA, Fiber U, tiene más de

dos docenas de cursos de autoaprendizaje gratuitos

sobre fibra óptica y cableado de instalaciones.

Como era de esperar, el tema más popular es el

curso "Fibra óptica básica", que se utiliza para

iniciarse en la fibra óptica y como curso de

preparación para realizar el examen de

certificación FOA CFOT.

Ahora el curso básico

de fibra óptica está disponible en español,

utilizando el libro de texto FOA en español, la

sección de la Guía en línea en español y la

capacidad de YouTube para traducir subtítulos de

video al español. El curso funciona exactamente

como la versión en inglés con 10 lecciones, cada

una con cuestionarios y una opción para tomar un

examen de Certificado de finalización.

Para presentar el nuevo curso de

español Fiber U, el examen Certificate of

Completion es gratuito, así que dígaselo a sus

contactos.

Curso Básico de Fibra Óptica

de Fibra U en español.

New Fiber U Course: Fiber Characterization

FOA has added a new course at Fiber U on Fiber Characterization. Fiber

characterization is the process for testing long fiber cable plants for