- In

This Issue

- Note

we have changed the format to place articles in

sections on one topic and all articles are dated so

you know if we repeat one - whcih we often do when

we think it's very important!

FOA

Turns 25

FOA History

Newsletter

Sections

Click

on any link to jump to that section

News

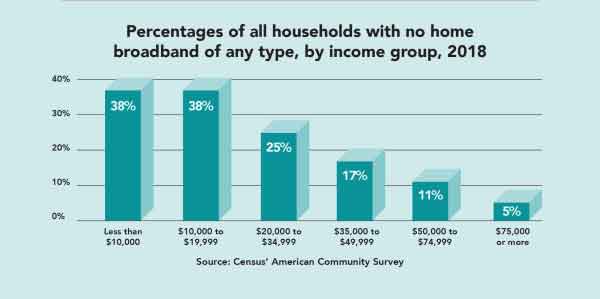

Google Fiber is back, Verizon to retire copper, Low prices

on media converters, Rural broadband only discriminates,

Construction worker killed on fiber install site, aerial

install messes

Technical

The mystery of loss in dB solved, splices on

OPGW, manufacturers of prepolished connectors, more

Worth

Reading New Pearson handbook, 600G,

cabling in the data center, NYTimes gives infrastructure

some respect, more

Q&A

As usual, new questions

Training/FiberU

Making training classroom safe, onine training,

materials, more

Resoures

Safety

About

FOA Certifications:

Certification

Renewals

Renew

your FOA certification online - plus get a discount on the

new FOA books and an extra month free. Details

here.

Jobs

- See

FOA Jobs

Web Page and FOA on

- The

FOA Jobs

Web Page has been updated and a new page added on Using

your FOA Training/Certification to Find the Right Job

in Fiber Optics

Where

Are The Jobs In Fiber Optics? FOA talks about all the

applications for fiber optics, what jobs involve and the

qualifications for the workers in the field in this YouTube

video.

Join

The FOA eMail Newsletter List

Want to

be notified when the FOA Newsletter is updated? Sign

up for the FOA eMail Newsletter. You can also

sign up from your cell phone: text "FOA" to 22828 (usual

text message charges apply)

Trademarks:

The FOA CFOT® (Certified Fiber Optic Technician) and

Fiber U® (the FOA online self-study program) are registered

trademarks of the FOA.

Want

to know more about fiber optics? Study

for FOA certifications? Free

Self-Study Programs are on "Fiber

U®." Looking for specific information? Here's the

largest technical reference on the web: The

FOA Online Fiber Optic Reference Guide.

Free

online self-study programs on many fiber optics and cabling

topics are available at Fiber

U, FOA's online web-based training website.

FOA

Reference Books

Available Printed or eBooks

The

fiber book is available in Spanish and French

Lennie

and Uncle

Ted's Guides are now also available as free iBooks on

iTunes.

Click

on any of the books to learn more.

- Fiber

Optic Safety Poster to download and print

FOA

Videos on

FOA

is a member of:

The

FOA Newsletter is edited by Jim Hayes - send your stories,

leads, ideas, comments to <jim @ foa.org>

Search

the FOA Website With DuckDuckGo

- The

Archives: Past Issues.

- Use

these links to read past issues or use FOA's

Custom Search to look for specific topics on our

website.

1/20,

2/20, 3/20.

4/20, 5/20,

6/20, 7/20,

1/19,

2/19, 3/19,

4/19,

5/19, 6/19,

7/19, 8/19,

9/19, 10/19,

11/19,

12/19

1/18,

2/18, 3/18,

4/18, 5/18, 6/18,

7/18, 8/18,

9/18, 10/18,

12/18.

1/17,

2/17, 3/17,

4/17, 5/17,

6/17, 7/17,

8/17, 9/17,

10/17, 11/17,

12/17

1/16,

2/16, 3/16,

4/16,

5/16, 6/16,

7-8/16, 9/16,

10/16, 11/16,

12/16

1/15,

2/15, 3/15,

4/15, 5/15,

6/15, 7/15,

8/15, 9/15

, 10/15,

11/15 , 12/15

1/14,

2/14, 3/14,

4/14, 5/14,

6/14, 7/14,

8/14, 9/14,

10/14, 11/14,

12/14

1/13,

2/13, 3/13,

4/13, 5/13,

6/13, 7/13,

8/13, 9/13,

10/13, 11/13,

12/13

1/12

, 2/12, 3/12,

4/12, 6/12,

7/12, 8/12,

9/12, 10/12,

11/12, 12/12

1/11

, 2/11,

3/11,

4/11,

6/11, 7/11,

8/11, 9/11,

10/11, 11/11,

12/11,

1/10

, 2/10,

3/10, 4/10,

05/10,

07/10,

08/10, 09/10,

10/10,

11/10

1/09

, 2/09,

3/09, 04/09,

05/09,

07/09,

08/09, 09/09,

10/09, 11/09,

12/09

1/08

, 2/08, 3/08,

4/08, 5/08,

6/08, 7/08,

8/08, 09/08, 10/08,

11/08, 12/08

12/07 , 11/07,

10/07, 09/07,

08/07, 07/07,

06/07, 05/07,

04/07, 03/07,

2/07, 1/07

12/06

, 11/06, 10/06,

09/06, 8/06,

7/06, 6/06,

5/06, 4/06,

3/06, 2/06,

1/06,

12/05

,11/05, 10/05,

09/05, 08/05,

07/05, 6/05,

5/05, 4/05,

2/05, 01/05,

12/04

, 10/04, 9/04,

8/04, 7/04,

6/04, 5/04,

4/04, 3/04,

1/04,

12/03

, 11/03 10/03

9/03, 8/03,

7/03, 6/03,

3/03, 10/02

, 8/02, 5/02

Current Issue of FOA Newsletter

Time

To Renew Your FOA Certifications?

To keep

your FOA certifications active, you need to renew them when

they expire. Now we have a new more convenient way to renew

- an online store at Paypal - where you can quickly and

conveniently use your PayPal account or your credit card to

renew your certifications.

- You

can now renew with PayPal or a credit card

-

PayPal

is available worldwide

Join

FOA On Social Media

FOA has

four LinkedIn Groups

FOA

- official page on LinkedIn

FOA

- covers FOA, technology and jobs in the fiber optic

marketplace

FOA

Fiber Optic Training - open to all, covers fiber optic

technology and training topics

Grupo

de La Asociación de Fibra Óptica FOA (Español)

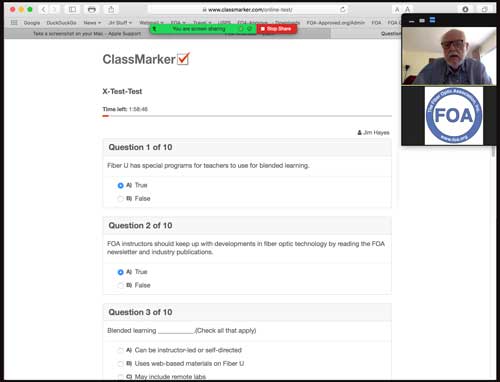

SPECIAL

OFFER - Save 1/3 On Your Certification Renewal Cost

In the

near future, there will be a requirement for continuing

education to renew your FOA certifications. FOA is testing

an option for renewals where you take a short Fiber U online

course.

If you would like to help FOA test this option, you can save

1/3 the cost of your renewal. Go

here to take the Fiber U CFOT Renewal Course: |

The

Fiber Optic Association

Introduction

The

Fiber Optic Association Inc. (FOA) is an international

non-profit educational association chartered to promote

professionalism in fiber optics through education,

certification and standards. FOA was founded in 1995 by more

than a dozen prominent fiber optics trainers and leaders

from education, industry and government as a professional

society for fiber optics and a source of independent

certification, the FOA has grown to now being involved in

numerous activities to educate the world about fiber optics

and certify the workers who design, build and operate the

world's fiber optic networks.

Founded soon after the initial commercialization of the

Internet, the FOA became a "virtual organization," perhaps

one of the first organizations so created. There is no FOA

headquarters building or any "brick and mortar" presence -

appropriate to its technology, FOA exists on the Internet

and in the work of its people. Those who run the

organization live and work all over the world, using modern

communications to communicate and collaborate. The network

of experts working to create the FOA knowledge base and

programs include our technical advisors who average more

than 20 years experience in fiber optics. Their experience

ensures FOA curriculum and certifications are the most

comprehensive and up to date available.

The

Beginning

The

Fiber Optic Association Inc. was created by the instructors

and participants of the 1995 Fiber U training conference

held in Boston. Fiber U was a week-long fiber optic training

event with mornings devoted to classroom courses and

afternoons to hands-on training by numerous vendors of fiber

optic equipment.

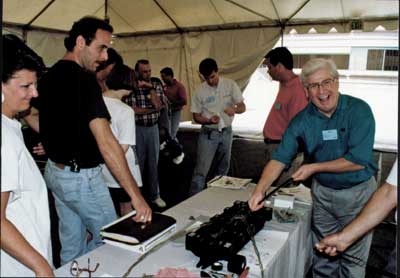

Eric Pearson teaches a class at Fiber U 1994 in Long Beach,

CA

Eric Pearson teaches a class at Fiber U 1994 in Long Beach,

CA

Fiber U was the creation of a company called FOTEC Inc. of

Boston, MA. FOTEC was started by Jim Hayes (founder and

current FOA President) in 1980 and began manufacturing test

equipment for fiber optics in 1981. By 1982, FOTEC began to

start training courses for its customers who were all new to

fiber optics. Throughout the 1980s, FOTEC ran short courses

in fiber optics around the US and eventually in many other

parts of the world. FOTEC was only in the test equipment

business, so it invited other manufacturers in areas like

fiber optic cables, connectors, splicing equipment, etc. to

participate in these courses.

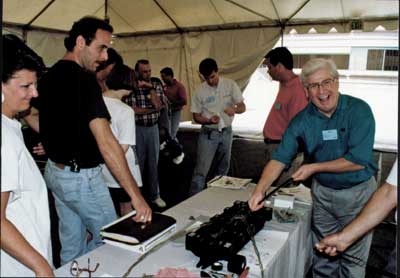

Dan Silver (R) of 3M demonstrates how to dress cables in a

splice closure at Fiber U 1994 in Long Beach (more

Fiber U photos)

Dan Silver (R) of 3M demonstrates how to dress cables in a

splice closure at Fiber U 1994 in Long Beach (more

Fiber U photos)

In 1992, Dan Silver, the fiber optic trainer for 3M Corp.

who was a regular participant in these courses, suggested

that FOTEC expand the program to become a full week

conference. That seemed like a good idea, so the first Fiber

U was held in Nashville, TN in 1993. It was a good idea -

over 200 students came from the US, Canada, Mexico and

several other countries and 40 vendors joined to offer

training. Fiber U became an annual event with international

participation.

During a meeting of instructors at Fiber U 1995, the

discussion focused on the need for a vendor-independent

certification for fiber optic technicians. Manufacturers had

contractor/installer certifications, but they were primarily

aimed at marketing the vendors products. Over lunch, the

decision was made to start a professional society for fiber

optic personnel and offer an independent certification for

techs. All the Fiber U instructors volunteered their

services to build the organization.

The instructors decided the industry was mature enough to

support a professional society and needed to create

industry-wide certifications. The founders included

experienced instructors from industry (3M, Siecor, Panduit,

FOTEC), government (US Navy and Air Force), education

(Lincoln Trail College and Wentworth Institute) and private

trainers (Pearson Technologies, Conquest Communications) who

were teaching fiber optics and who provided the expertise in

management, technology and education needed to create a new

professional society.

In July of 1995, The Fiber Optic Association was

incorporated in Massachusetts and was recognized as an

educational non-profit corporation, 501(C)(6), by the IRS.

The FOA charter was (as it still is now) to promote

professionalism in fiber optics through education,

certification and standards.

The FOA decided to use the new communications medium, the

Internet, to create an international professional society

that would utilize the expertise of the Fiber U participants

without the financial overhead of a traditional

organization. The FOA website, created at the beginning, was

one of the earliest websites for an organization.

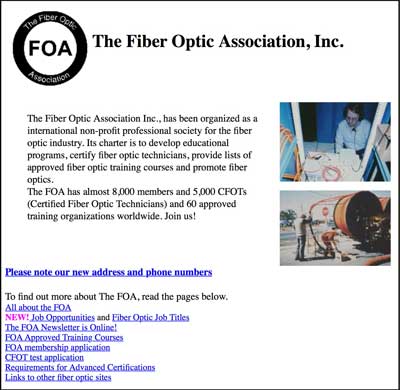

FOA website ca. 2000 (view

here on the WayBack Machine Internet Archive)

FOA website ca. 2000 (view

here on the WayBack Machine Internet Archive)

Who

Were The FOA Founders?

Those

listed below in BOLD are still active teaching and working

with FOA. See Profiles below.

Jim Hayes, President of FOTEC Inc. Pioneering fiber

optic entrepreneur in test equipment and trainer who was

trained in physics/astronomy. Author of many EIA/TIA

standards and the instigator of the NBS/NIST fiber optic

calibration program. Creator of the Fiber U training

conferences. Author of ten textbooks, hundreds of

technical articles. Current FOA President. See Profiles

below.

Eric Pearson, Pearson Technologies. Trained by

Corning in the 1970s, considered an industry expert on

termination and splicing, training since the early 1980s.

Respected expert witness in legal cases. Active FOA

Instructor. See Profiles below.

Dominick Tambone, Engineer, Automatic Tool and Connector,

fiber optic termination and installation, training since

the early 1980s. Contractor and Active FOA Instructor.

Bill Graham, Mississauga Training Associates,

Toronto, ON, CN. Background in utilities, military,

metropolitan fiber optics, training since the early 1990s.

Current FOA Director. See Profiles below.

Prof. Elias Awad, Wentworth Institute, Boston, MA. Started

one of the first fiber optic academic programs in the

engineering department in late 1980s. Creator of NSF

program “Fiber Optics For Engineering Technology”

(NSF#9353997).

Prof. John Highhouse, Lincoln Trail College, Robinson, IL.

Head of telecom training program, started teaching fiber

optic outside plant construction in late 1980s. Masters in

Education, specialty testing. See Profiles below.

Paul Rosenberg, writer and technical trainer

Dan Silver, Product Specialist, 3M Fiber Optics, trainer

and applications. The man with the idea to create the

Fiber U training conferences and active FOA member.

Eric Loytty, Field Engineering, Corning/Siecor,

applications and training.

Bob Mason, Product Manager, Network Systems, Panduit,

applications and training.

Doug Elliott, IBEW Instructor, Toronto, ON, CN. One of

first IBEW apprenticeship instructors to teach fiber

optics.

Tom Collins, Northern Kentucky Technical College,

Professor. Techtricians, Owner/instructor. Current FOA

Director. See Profiles below.

Dan Lyall, Project Engineer, Lockheed Martin, applications

and training.

Jim Davis, Program Director, U. S. Navy Navsea 56ZC, Navy

fiber optic standards.

Dave Chaney, Disney, Network Manager

Tony Beam, Tyco/AMP, Product Manager

Richard J. Smith, FOTechnologies, Technican/Instructor

Profiles

Of FOA Founders Still Active

Jim

Hayes, FOA#1, Founder and President, and Karen Hayes, VP

Administration

Jim

Hayes working with IMSA Instructors on lab techniques

Jim

Hayes working with IMSA Instructors on lab techniques

Jim Hayes was recruited into the fiber optic business by

the scientists at Bell Labs who were developing the

technologies in the late 1980s. They wanted the company

he worked for to build test equipment for AT&T. When

his company declined the opportunity, Jim and his wife

Karen, now FOA VP Administration, started one of the

world's first fiber optic test equipment companies in

1980, called FOTEC for, simply enough the Fiber Optic

Test Equipment Company. FOTEC quickly became involved in

training people in this new technology, inviting other

manufacturers to participate, leading

to the Fiber U training conferences. FOA evolved from

Fiber U as a certification body for the fiber optic

industry. Jim has remains active in FOA, serving as

President, writing and editing the FOA textbooks,

newsletters and online Guide, while Karen manages daily

operations as she has done since the beginning and

generally avoids the limelight.

Karen (R) inspects a traffic management system during a

training program in Mesa, AZ.

Eric

Pearson, FOA #5, Pearson Technologies

Eric (back row, right) shows students how to

interpret their work.

Eric Pearson and Jim Hayes are probably the two FOA

Founders with the most years in fiber optics, both started

in the late 1970s and are still active today. Eric began in

the fiber optic cable business, then transmission systems

and designed field installation equipment. He began training

more than 30 years ago and has published his workbooks and

manuals as what we like to call the "cookbooks" of fiber

optics. Eric may be the world's top expert in the process of

fiber optic termination and his books certainly are the best

manuals for termination. Eric still travels the world

doing training courses, finds time to continue writing and

updating his books (See

note below

on the new Kindle version of his installation

handbook) and consulting as an expert

witness in legal cases.

Eric

Pearson, Pearson Technologies

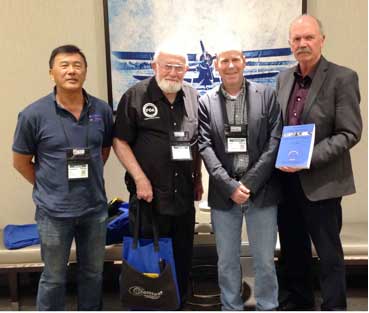

Bill

Graham, FOA #168, Director, Representing FOA In "The

Frozen North"

Bill

Graham (second from left above with the white beard) lives

near Toronto and has probably trained half of Canada in

fiber optics. Bill sold his company, Missisauga Training,

several years ago to another active Canadian who

took over the training but Bill is still active as a FOA

Director and promoter in Canada. Bill is famous for training

in the Frozen North, still in competition with Ian Gordon

Fudge of Fiber DK in Denmark to see who has trained closer

to the North Pole. Bill always sent us photos from his

trips, like these:

Tom

Collins, Director, FOA's IBEW and IMSA Liaison

Tom Collins joined the FOA while a teacher at Gateway

Community and Technical College near Cincinnati, OH. Tom has

about 40 years of experience in the electrical and voice and

data fields. He is a master electrician, voice and

data technician, fiber optic technician, contractor, and a

technical instructor. His experience as an electrician and

apprenticeships has proven invaluable for FOA as Tom has

become FOA's liaison to the IBEW apprenticeship program and

has trained numerous IBEW apprenticeship instructors

at their National Training Institute (Tom's at NTI 2016

above).

Tom became a FOA Director almost 20 years ago and we've

benefited greatly from his experience. He and John Highhouse

created the FOA Train-The-Trainer program and FOA's unique

in the industry instructor certification program. Tom has

helped us understand technical training issues, online

training and testing and a lot of other educational topics.

Tom has a training partner too, his wife Donna, a FOA CFOS/I

instructor herself. Together they have been instrumental in

helping the FOA develop and manage its certification

programs.

John

Highhouse, FOA #2, Retired, Still Influences FOA

Activities

John Highhouse teaching a FOA Train-the-Trainer

Course

John Highhouse teaching a FOA Train-the-Trainer

Course

John

Highhouse started the first OSP/telecom college program

for fiber optics at Lincoln Trail College in Southern

Illinois. John was a Fiber U instructor and FOA

founder. He participated in the development of FOA

technical materials like our original textbook and the

CFOT certification. One thing John brought to the group

was his background in education with a specialty in

testing. He taught us how to test properly and fairly:

have definitive reference materials for the test that can

be also used for developing curriculum and develop test

questions that determine if the applicant's knowledge is

adequate. FOA still uses the test methodology that John

taught us before he retired.

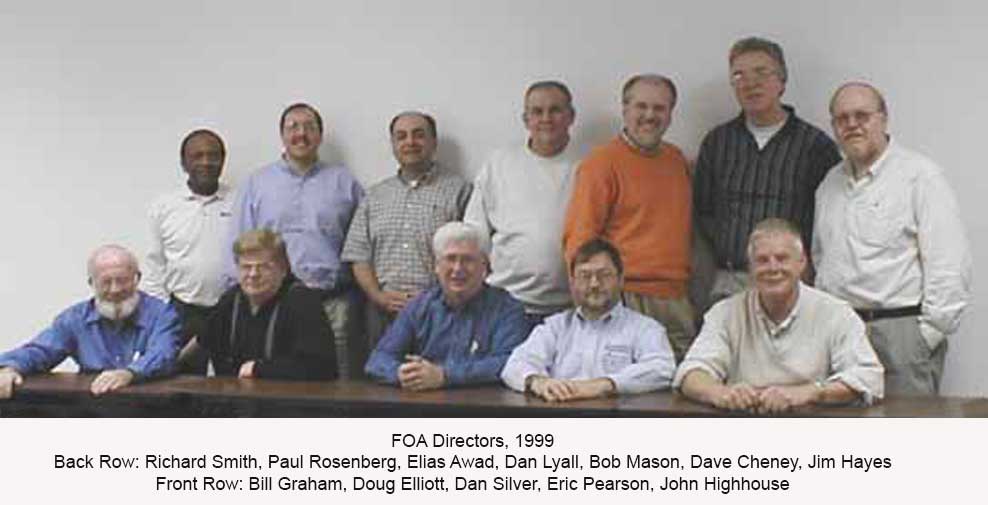

Certification Program Development

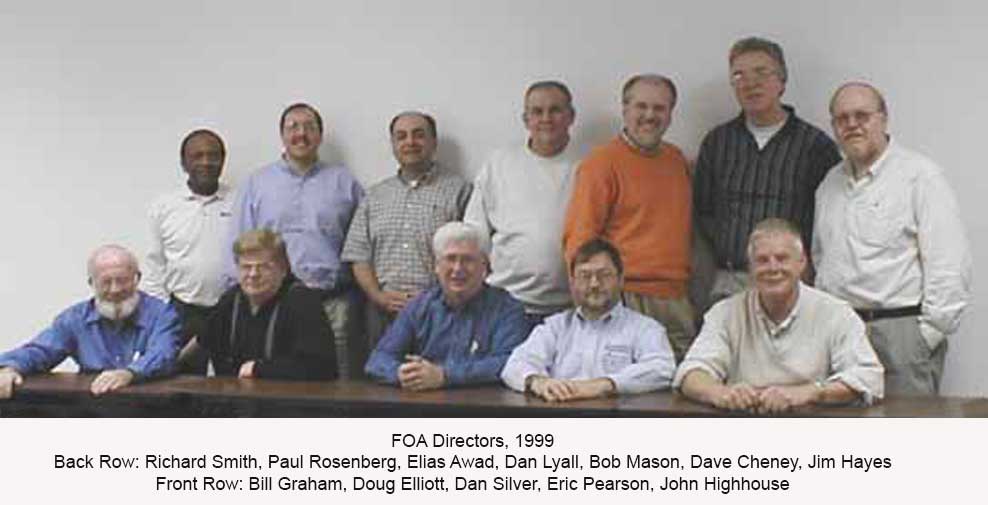

FOA

Advisors Meeting in 1997. FOA

Advisors Meeting in 1997.

From left around the table: Eric Pearson (Pearson Tech), Bob

Mason (Panduit), Dominick Tambone (Automatic Tool &

Connector), Dan Silver (3M Fiber Optics), Elias Awad

(Wentworth Institute of Technology), Doug Elliott (IBEW

Toronto), John Highhouse (Lincoln Trail College), Dan Lyall

(Martin Marrietta) and Eric Loytty (Siecor), photo by Jim

Hayes

This group of FOA founders began meeting quarterly and

collaborating via email while working to analyze the job

tasks of the fiber optic technician and creating a list of

knowledge, skills and abilities(KSAs) that such a technician

should have. It was an excellent group for this task as they

represented many aspects of the fiber optic field and all

had many years of experience. New recruits joined also. Tony

Bean, an applications engineering manager at AMP who had

previously worked at Siecor, Paul Rosenberg, a trainer for

electrical trades and author who with Hayes had written the

Data Voice and Video Cabling textbook and Dave Chaney, a

contractor who became network manager for Disney Corp. also

joined FOA to assist in the development of FOA programs.

The FOA

Board of Advisors 20 years ago, meeting to work on FOA

certifications.

One aspect of the creation of a general fiber optic

certification was the different types of applications that

fiber optic technicians were involved in. Technicians

working for phone companies building long distance or

metropolitan networks (OSP or outside plant networks) had

different job tasks that those working on premises cabling

for LANs (local area networks), or those in the military

building tactical systems or cabling on platforms like

ships, helicopters or airplanes.

The group was able to define the basic knowledge, skills and

abilities (KSAs) expected of all fiber optic technicians, no

matter their specific applications or jobs. In addition, the

group identified three areas of skills that were often jobs

done by fiber optic specialists: splicing, termination and

testing. These were also identified as subjects for

specialist training and should be considered for specialist

certifications.

It became obvious that FOA was not going to be a training

organization; that would be impossible in light of the

international scope of the organization. Training would be

the duty of the schools, manufacturers and independent

trainers who had been training fiber optic technicians for

over a decade. The FOA would set the standards for

certifications and manage the certification programs and

leave the training to others.

Then the task of creating a certification program began in

earnest. At this stage, the academics became the group

leaders, offering their expertise in development of

educational programs. Professor Highhouse became the project

leader. He created the checklist of requirements for a

certification: KSAs from job task analyses, reference

materials for trainers to use to develop curriculum and for

students to study, criteria and procedures for certification

examination and the examinations themselves.

Developing Reference Materials

The first task for the advisors was to identify reference

materials. A problem was immediately identified. Textbooks

on fiber optics were too theoretical and none dealt with the

installation processes. Materials on installation were

available from manufacturers but were all specific to their

products. There were no reference materials deemed

acceptable, so the decision was made to create a proper

textbook for fiber optic technicians.

The task of editing the book was accepted by Jim Hayes who

had already created a self-published a book on fiber optic

testing for his company FOTEC. The material in that book

became the chapter on fiber optic testing for the new

technician book. Others contributed their expertise.

Everyone contributed to the chapter on applications. Prof.

Awad had created a curriculum on basic fiber optics under an

NSF grant and it was adapted to become the chapter on the

basics of fiber optics. Eric Pearson and Dominic Tambone

created on the chapter on termination and splicing.

Professor Highhouse, Dan Silver and Eric Lloytty wrote

sections on installation.

The material for the textbook was produced quickly as the

authors were all experts in their field and created chapters

on their expertise. Delmar, the publisher of technical

books, became the publisher and the first edition of The

Fiber Optic Technicians Manual (ISBN 10: 0827374267)

was released in 1996. The book was described by Delmar

thusly: “This book is intended for training installers of

fiber optic networks. Technicians and electricians eager to

learn more about fiber optic design, installation, and

troubleshooting will find this book a practical and

comprehensive source, useful in both training and self-study

situations.”

At the same time, FOA began creating a website with the

basic fiber optic information contributed by the advisors

made available to everyone online. That website, the FOA

Online Guide, has been expanded and updated continually

until today.

Creating A Certification Exam

With the job analysis and KSAs as a reference guide,

Professors Highhouse and Awad and their collaborators began

creating criteria for classroom and laboratory training and

an exam of the knowledge of certification candidates. The

training aspects were covered in an Instructor’s Manual

created by the FOA that described the classroom and hands-on

labs expected for certification. In the process of creating

an exam covering the knowledge part of the exam, Professor

Highhouse created guidelines for creating tests and test

questions still in use by the FOA today.

The first FOA exam for certification was made released by

the Board in 1997. The certification by that time had a

formal name, Certified Fiber Optic Technician, CFOT. The

certification was first offered by the founders of the FOA

to their own students to verify the program before expanding

to other training venues. The examination process involved

the instructors who were tasked to verify that students

showed appropriate skills and abilities during hands-on

activities before taking the examination given at the end of

the course.

Expanding The Scope Of The FOA

During this development process, the FOA had been introduced

to the world as the international professional society of

fiber optics. Interest in the FOA certification program was

high and trainers around the world began asking to become

part of the program. When the FOA advisors agreed that the

CFOT was ready to be offered by more trainers, applications

were accepted from trainers and training organizations.

Criteria for potential trainers were established by the

advisors that included requirements for curriculum in the

classroom and hands-on labs, including required training

equipment. Educational institutions, commercial trainers and

fiber optic manufacturers or vendors made applications. The

advisors realized that to maintain the integrity of the

certification, it was necessary to create an agreement with

the schools or trainers that covered all aspects of the

certification process and included regular reviews of their

performance.

Some applicants, especially in the academic world, had

little or no practical knowledge in fiber optics, so it was

necessary to help them learn the knowledge and recommend to

them venues to acquire the hands-on skills necessary. Many

used the Fiber U conferences which had partnered with other

organizations like the National Electrical Contractors

Association, the COMNET conference, etc. to offer training

at many conferences and meetings. Others used other

FOA-approved trainers or vendors for training. To provide a

guide to skills training, FOA personnel led by Pearson,

Tambone and Hayes developed a Fiber Optic Lab Manual that

described in detail the processes used in fiber optic

installation and how they should be taught in labs.

John Highhouse

conducts class at FOA TTT 2002 John Highhouse

conducts class at FOA TTT 2002

FOA began planning its own Train-The-Trainer program to be

held at Gateway Community College where Professor Tom

Collins taught. Prof. Collins had joined the FOA advisors

after attending Fiber U and creating his own program at

Gateway and the IBEW apprenticeship program in Cincinnati.

The first FOA T-T-T was held in 2002 at Gateway, run by

Professors Collins and Highhouse and introduced the FOA

certification for instructors, CFOS/I, Certified Fiber Optic

Specialist in Instruction. After several years of T-T-T

classes, the instructor training was primarily moved online.

Meanwhile, advisors Pearson, Tambone and Hayes were heading

a group working on skills specialist certifications in

splicing, termination and testing. Job analyses were done

and KSAs created for CFOS/S, Certified Fiber Optic

Specialist, Splicing, CFOS/C, termination with connectors

and CFOS/T for testing. These skills-based certifications

had greater requirements for hands-on labs, with more

equipment and time for hands-on activities required. Exams

were developed with Professors Highhouse and Awad using the

criteria they had created. Instructor manuals were developed

to assist instructors in setting up appropriate training.

FOA schools were then authorized to offer these specialist

certifications.

A Virtual Organization

As mentioned earlier, the FOA was a professional society of

the Internet age. There was no physical presence, per se,

and no employees, just a few contractors and many

volunteers. Income from certifications, initial and renewal,

and book royalties was sufficient to pay outside services

like administration and accounting. By 2002, the daily

operations required more time and attention, so Jim Hayes

and Karen Hayes, having sold their company FOTEC, were

contracted to manage the organization and provide technical

leadership, a role they still fulfill today. FOA also has

contracted administrative, bookkeeping/financial, software,

media and legal services as needed. In 2003, the FOA was

legally moved to California when the Hayes’s moved to

Southern California.

Growing Into The 21st Century

The early 2000s were a development time for the FOA and its

network of schools expanded worldwide. Although the fiber

optic industry in the US experienced a severe recession in

2001-2 as the large Internet growth of the late 1990s turned

out to be a bubble, the FOA continued to grow, particularly

overseas. Programs and operations were continually improved

and updated as technology and applications evolved.

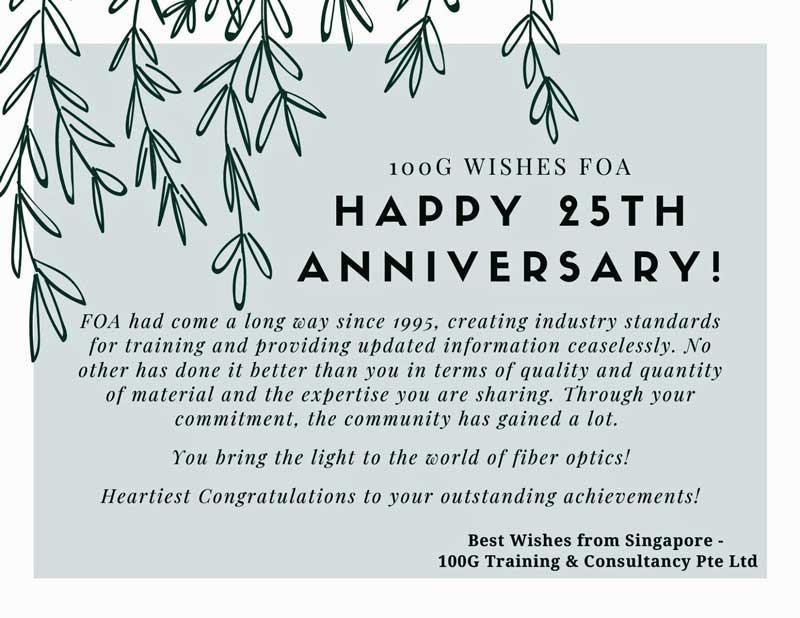

With

the internationalization of the FOA, the advisors expanded

to include some very qualified people. Joe Botha, owner of

Triple Play Fiber Optics in Durban South Africa was

training fiber techs throughout sub-Saharan Africa and

working with governments and telecom companies on manpower

development. Ian Gordon Fudge of Fiber DK in Copenhagen,

Denmark was a consultant and authorized trainer for many

fiber optic and communications companies working an area

from the Arctic to the Middle East. Bee Suat Lim of 100G

Training and Consultancy in Singapore was involved with

projects in Southeast Asia. These three have been major

contributors to the development of FOA technical resources

and certifications, as have many others involved in the

FOA organization.

Like all organizations, the FOA's development was dependent

on a group of highly competent, highly motivated individuals

devoted to educating the fiber optic community. Some of the

instructors and training organizations that were

instrumental in FOA's growth deserve special recognition.

Bob Ballard

of BDI Datalynk and one of his classes Bob Ballard

of BDI Datalynk and one of his classes

Bob Ballard started BDI Datalynk, a training organization

with a unique approach: Make the classroom look like the

real world then pack it into the back of a van. Carry it

around the country and partner with the continuing education

departments of colleges to offer FOA certification classes.

Bob sold BDI and retired in 2018.

Joe

Botha of Triple Play in his element, teaching in Zambia Joe

Botha of Triple Play in his element, teaching in Zambia

Joe has been instrumental in training techs throughout

Sub-Saharan Africa. Joe is also creator of the FOA OSP

Construction textbook.

Ian Gordon Fudge of Fiber DK teaching students how to splice

OPGW in Greenland. Ian and FOA Director and Canadian Bill

Graham have a friendly competition to see who has trained

more places in the far North.

Ian Gordon Fudge of Fiber DK teaching students how to splice

OPGW in Greenland. Ian and FOA Director and Canadian Bill

Graham have a friendly competition to see who has trained

more places in the far North.

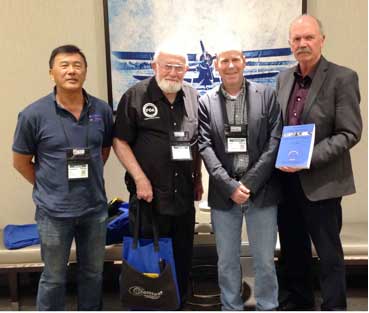

Bee

Suat Lim, Director (R) and Isaac Yeo Hock Lai (L) of 100G in

Singapore with Karen and Jim of the FOA during a visit to SE

Asia. Bee was instrumental in creating the FOA textbook on

Fiber Optic Network Design and training techs in SE

Asia. Bee

Suat Lim, Director (R) and Isaac Yeo Hock Lai (L) of 100G in

Singapore with Karen and Jim of the FOA during a visit to SE

Asia. Bee was instrumental in creating the FOA textbook on

Fiber Optic Network Design and training techs in SE

Asia.

Jerry Morla, 2nd

from R, at a meeting of FOA instructors in Atlanta, is the

latest FOA Director to join us. Jerry, who came on board in

2008, is FOA's ed-tech person, looking at new methods using

technology to make learning better and more efficient, a

valuable asset in these times of social distancing and

isolation. Jerry Morla, 2nd

from R, at a meeting of FOA instructors in Atlanta, is the

latest FOA Director to join us. Jerry, who came on board in

2008, is FOA's ed-tech person, looking at new methods using

technology to make learning better and more efficient, a

valuable asset in these times of social distancing and

isolation.

Partnering and Promoting FTTH Since 2006

In

2006 when FOA was approached by Verizon to assist them in

recruiting and training personnel for a new program of fiber

to the home expansion called FiOS. FOA advisors worked with

Verizon technical personnel to understand the new passive

optical network technology (PON) being used, the

installation practices they were developing and create

reference and educational materials to support training. In

addition, In 2007 FOA and Verizon did several seminars

together on both coasts to educate trainers and contractors

and help Verizon’s recruiting efforts. This work led to the

new FOA specialist certification in FTTx or Fiber to the

Home/Business/Curb, etc., FOA’s first application

certification. This certification was uniquely structured to

be appropriate for both technicians who would be installing

FTTx and managers who needed to be trained in the new

technology that their company was promoting and installing.

FOA and Verizon ran this FTTH Summit in LA in 2007

FOA and Verizon ran this FTTH Summit in LA in 2007

The success of the FTTx certification program encouraged the

FOA to create several new certifications. Professor Tom

Collins worked with FOA to develop a certification in

premises cabling based on standardized structured cabling

for LANs (local area networks for PCs), but expanded to

include copper and fiber cabling and the rapidly growing

WiFi wireless technology. Several schools wanted a

specialist skills certification for outside plant

technicians which was also developed, then later updated

with material from advisor Joe Botha’s construction course

to include aerial and underground construction. Other

certifications were created at the request of instructors,

schools and industry groups, including optical LANs and

fiber optics to support wireless networks.

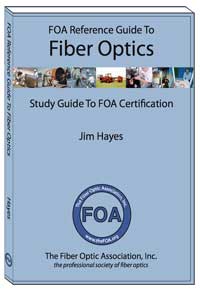

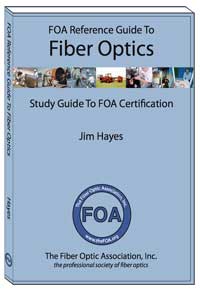

FOA As A Publisher

As the FOA grew, the FOA Guide’s online technical material

became a trustworthy resource for people looking for answers

about fiber optic topics. But the FOA textbook was a

preferred resource for those who still liked their

information on paper.

While FOA was regularly updating its online technical

material and exams to keep up with technology, the textbook

publisher was much slower to update the textbook which

became a problem. In 2008 as the world entered another

recession, the publisher postponed an update and raised the

price of the book to a point the FOA schools objected. FOA

did a survey of publishing, decided that publish-on-demand

technology was a more acceptable alternative and began

creating its own textbook, The FOA Reference Guide To Fiber

Optics, based on the online technical materials on the FOA

website. The FOA Online Guide had grown to hundreds of pages

of technical materials and became the most popular reference

for fiber optics online, with over one-half million visitors

downloading about four million pages of the FOA Guide in

2018.

FOA's

self published fiber optic textbook for CFOT certification FOA's

self published fiber optic textbook for CFOT certification

The new self-published FOA textbook was an immediate

success. It was more up to date, better organized for both

teaching and reference and, even at about one-fourth the

price of the previous book, contributed more royalty income

to the FOA. In addition, it could be updated anytime, so the

FOA has since combined the textbook review with the annual

review of the CFOT certification program, updating them in

concert.

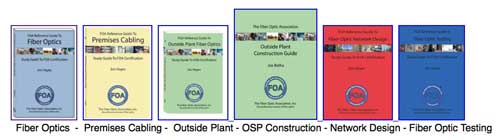

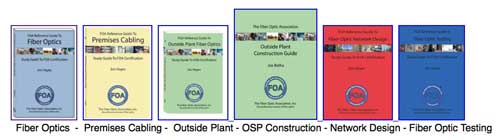

The ease and success of self-publishing encouraged FOA to

expand its offering of books. The original book was

translated into Spanish and French for our schools who

taught in those languages. Additional books were introduced

to support FOA certification programs in fiber optic network

design, outside plant installation, premises cabling and

fiber optic testing. FOA also printed the textbook created

by one of our advisors, Joe Botha in South Africa, for

outside plant construction.

FOA Became A Resource For The Industry

FOA began an online newsletter in the early 2000s, covering

news of the industry, interesting applications, new

components and what became a favorite section, “Good

Question.” The FOA had been getting calls and emails from

people looking for advice which we were able to answer by

using the broad expertise of our advisors. This column in

the newsletter gave the FOA an indication of what people

wanted to know and insight into issues in the industry.

Those questions led to new pages in the FOA online Guide to

expand on the answers and have been archived on the FOA

website. Today the newsletter has about 20,000 readers per

month and the questions keep coming, several every day.

As the FOA Guide grew to nearly 1,000 pages of technical

information and was used more and more, it rose to the top

of web searches, increasing its audience even more. After

twenty years of growth, the FOA Guide has nearly a

half-million visitors each year downloading almost 4 million

pages of technical information.

As the Internet became capable of supporting video, FOA

offered tutorials online on many aspects of fiber optics.

With the advent of YouTube, FOA created a YouTube channel,

thefoainc, that hosts over 100 videos, including 50 lectures

and an equal number of hands-on tutorials. The FOA YouTube

channel has almost 20,000 subscribers and over 3 million

views.

Online Education For Free

Along with the Fiber U technical material, the FOA obtained

the name “Fiber U”, and used it to create an online

self-study website, fiberu.org, inspired by the original

Fiber U online created in 1997. Fiber U was one of the first

online learning sites based on the work of a Boston school

teacher who had developed it for Boston teachers. While he

was a summer intern at FOTEC, he created Fiber U online

based on the FOTEC/Fiber U online technical website, and it

became an immediate success.

Since the FOA Online Guide was so extensive, FOA used Fiber

U as a way to assist anyone wanting to learn about fiber

optics and for experienced fiber techs to study before

challenging the FOA CFOT exam without taking a training

class. Several instructors, led by Professor Tom Collins,

used Fiber U as part of a blended learning program for their

college students, with online study replacing some classroom

lectures, allowing in person classes to be primarily devoted

to hands-on labs. While Fiber U has been a valuable way of

assisting people learning about fiber optics and preparing

for FOA certification, it is not used for direct

certification, only as a learning aid. Actual certification

requires training and/or taking an exam while proctored.

FOA Assistance With Fiber Optic Projects

Quite a few inquiries the FOA gets are about fiber optic

network projects. The projects vary from metro traffic and

surveillance networks, independent fiber to the home (FTTH),

industrial (oil and gas, chemical, automotive, etc.),

government/military and much more. FOA provides free advice

on a technical level and contacts needed for the projects.

FTTH has been a popular topic and FOA has assisted in

projects as diverse as Southern Fiberworx, a FTTH project

done entirely internally by a real estate developer and Anza

Electric Cooperative’s project in the CA mountains that

became known as “fiber to the ranch.” Other FTTH projects

have been in areas as diverse as Lebanon and South Africa.

FOA has also been involved in optical LANs based on FTTH

technology that has become very popular in the government,

medical and hospitality fields.

FOA provides this assistance at no cost, considering it part

of our original charter as a professional society. Of

course, all the projects require qualified technicians to

design, install and operate them, thus promoting the FOA and

its certifications, Many of the projects also require

training personnel which benefits the FOA network of

approved schools and its certification programs. And the FOA

network of advisors often take over to provide assistance to

the projects locally.

All

of this work, the free technical reference materials and

online training, assistance in answering inquiries and

providing contacts has made FOA the center of fiber optic

activity and a trusted source of information.

Partnerships And Affiliates

FOA’s expertise in the fiber optic field has led to

partnerships with other organizations wanting to provide

their groups with that training. Several members of the

FOA founders and early advisors (Hayes, Elliott, Graham,

Collins) were involved with the IBEW/NECA NJATC

telecom/low voltage apprenticeship program, the largest

technical apprenticeship program in the US. FOA became a

partner with the NJATC to assist them in developing their

program in fiber optics, participating in their annual

National Training Institute for instructors, and has

trained hundreds of JATC instructors who teach for the FOA

CFOT at over 30 local union apprenticeship training

centers.

FOA works with IMSA, a century-old professional society

for traffic control engineers to provide CFOT

certification. The Communications Workers of American

Alliance uses FOA certifications to ensure competence for

their workers. FOA is now assisting IPC, a trade

association for manufacturers of hardware primarily for

aerospace industry, create a fiber optic certification

program. FOA has worked with EPRI, the Electric Power

Research Institute, to create a Strategic Guide To Fiber

Optics for their member utility companies.

Fiber optic manufacturers like Corning and Clearfield,

telecommunications companies around the world like

Cincinnati Bell and Etisalat in UAE and many more use FOA

programs for training and certifying employees and

customers.

Hundreds of companies, agencies and organizations

worldwide use FOA certifications as a measure of

competence for employees and contractors. FOA-certified

techs build telecom landline and wireless networks, CATV

systems, utility networks, data centers, explore for oil

and gas, operate remote-operated vehicles for undersea

exploration, build military strategic and tactical

networks and hundreds of other applications, literally

from pole to pole.

Standards And Technology

FOA has been involved with standards programs for many

years. FOA is a member of the TIA and ANSI and a

participant in the TIA TR-42 committee on fiber optics and

cabling. Jim Hayes is the usual FOA representative in the

standards committees as he has been involved with

developing fiber optic standards since 1983 at TIA, ANSI

and several military standards groups. While at FOTEC, the

fiber optic test equipment he founded in 1980, he

convinced the US National Bureau of Standards that a

standard was necessary for fiber optic measurements

leading to the NBS/NIST program for calibrating optical

power. He is the original author of EIA/TIA standards

FOTP-95 and OFSTP-7/14 and a contributor to numerous other

standards dating back to the 1980s. Other FOA members have

been actively involved in standards, including founding

member Jim Davis who was the project leader of the

military standards group NAVSEA-56ZC until his retirement.

FOA partnered with NECA (National Electrical Contractors

Association) in their NEIS (National Electrical

Installation Standards) program to create

ANSI/NECA/FOA-301, a standard for the installation of

fiber optic cable plants. Today FOA maintains an active

role in the TIA and monitors other standards groups for

information important to the fiber optic field. FOA helps

explain their meaning and importance to the readers of its

technical materials. FOA is considering becoming an active

ANSI standards member and creating standards for fiber

optic network installation. FOA

has worked with organizations like the US Department of

Labor to create job descriptions for fiber optic techs and

assist in standards for workplace certifications.

FOA advisors had a long history participating in industry

standards and co-operative R&D projects. The

organization has taken on several technical projects

itself in topics of interest to the fiber optic industry,

many in the field of testing. Pearson and Hayes

investigated the correlation of optical loss test sets

(OLTS) and optical time domain reflectometers (OTDR) in

multimode tests with mode conditioners. Terry O’Malley, an

FOA advisor who created and gave training at AT&T on

OTDRs has done several projects to show how OTDR traces

show events of interest such as low reflection APC

connectors and the condition of the end of an optical

fiber that is broken. Joe Botha in South Africa did

projects with his students on splicing dissimilar

singlemode fibers. Two FOA advisors, Bill Graham and Ian

Gordon Fudge, have a ongoing contest of who can do

training closest to the North Pole and they share their

experiences in cold-weather applications through the FOA

newsletter and website.

As a certifying body, FOA has been following the

guidelines of ISO/IEC 17024, the international standard

for certifying bodies, following its guidelines to create

a better certification program.

Statistics

As of July 2020, our 25th Anniversary, FOA has

certified more than 81,000 technicians who have achieved

over 110,000 certifications. FOA has approved

schools offering FOA certifications in more than 40

countries around the world. Besides the US, FOA

instructors teach in locations as varied as First Nation

villages in the Canadian Arctic, villages in Greenland,

the Middle East, most countries in Africa, South America

and Asia. FOA’s Advisory Board has members in the US and

Canada, Copenhagen, DK, Durban, SA, Singapore, Nairobi,

Cairo, and more, assuring the FOA maintains an

international perspective on the fiber optic field.

FOA's

Longest Active CFOTs

As part

of our 25th anniversary, FOA tracked down the earliest CFOTs

still

active in the industry - many more than 20 years. Those

marked * are still active educators!

We are probably missing some that did not respond to our

emails or are not listed as active in our certificants list,

so it you think you belong in this group, please email us!

*Jim

Hayes #001

*Eric Pearson #005

*Peter Olders #013

Bruce Trefethen, CFOT #017

Ron Blanding #106

Craig S. Danielson #107

*Bob Kinney #115

*Bill Graham #168

Dominick Tambone #237

*Milt Murry #545

Michael L. Masucci #737

Ron Hanes #752

*David

Engebretson #773

*William “Van” Ewert #1076

*Tom Norwood #1125

*Guy Sanford #1177

*Ron Szpila #1253

*George Lister #1684

*Leonard

Wasser #1685

*Levi West #1821

Julie K #2035

Juan D. Hinojosa #2122

*Tom Collins #3368

*David Schaefer #6800

*Anthony Flaris #1000050

*Jimmy Franko #1000052

Paul

Jimenez #138000

Robert Dancy #1420015

Comments

From Some Of The People Who Helped Build The FOA

John

Highhouse: I just remember us at our first

meeting discussing the importance of putting together a

certification program that had real standards and not

just some "mail order certification". I believe it

worked quite well as evidenced by the high regard people

have for the FOA name. Thanks for all you've done

for the industry. I honestly think that you got

the ball rolling and kept it straight down the

alley. Congrats for 25 excellent years.

Joe Botha: An educational association

reputation is something that you should consider when

choosing a place to study. You should focus your attention

on those that have name recognition and are known the

world over for being “good”. The FOA embodies “good”. FOA

is particularly known for its more than ample online

resources. Access to approachable, helpful, and passionate

about their subject matter experts. And you will be able

to find amongst a wide selection, the right course or mix

of courses to suit your interests and career ambitions.

Bob Ballard: Happy 25th Anniversary to the FOA -

my past business "partners"! I would like to say,

"thank you" for your many years of dedication to the fiber

optics industry and may it continue its growth in the

future - especially during these uncertain times.

You have provided this industry with an endless supply of

professional guidance, course curriculums, and market

knowledge.

I would like to offer a very special "thank you" for

allowing me to be a part of your organization for the past

17 years. Now, in my retirement from the fiber

optics industry, I look back on the extremely successful

opportunities your organization allowed me to be a part

of. The overall growth and success of my company can

only be attributed to your efforts to provide only the

best and most current fiber optics training curriculums

available anywhere in the world. Thus, the FOA

allowed me to use these materials, its guidance and its

website to build one of the largest and most successful

fiber optics training companies in the world.

Unfortunately, times, circumstances, and opportunities

have changed and, while the current road is not as clear

as it was in the early days, the FOA is there to assist

and, hopefully, will be there for many more years to come.

Thank you FOA for many past years of success in this great

industry.

Bill Graham: While Fiber Optic training was my

main occupation, I found myself involved in many other

industries such as mines, nuclear, aviation, industrial

machines, homes and many places using optical fiber, in

many case of odd types and sizes of fiber. Work in this

field took me to the USA, Europe, Caribbean, Baffin Island

and the furthest First Nation reserves in Northern Canada.

I joined the Fiber Optic Association and became a

Director. I found myself part of a group of the most

knowledgeable people in the industry. The original group

represented many facets of the industry. Jim and Karen

Hayes took the lead and have to be credited with the

original organization of the FOA as well as their

dedication bringing the FOA to the present state. The

industry owes them a debt of gratitude.

The rest of the years to this date have been terrifically

exciting, learning new technics in an ever changing,

life-long learning industry and meeting great people as

students and as vendors. All in all, it has been an

exciting trip and I am eternally grateful to all the great

people with whom I have been associated with over the

years.

And from FOA Director Jerry Morla, a relative newcomer

to FOA (2008): Over the last 25 years, the FOA has

incessantly worked to deliver on its mission of

professionalizing the fiber optics industry. After over

two decades, de FOA has achieved to contribute to the

development of hundreds of thousands of fiber optic

technicians and industry professionals around the world,

resulting in direct impact and quality gains for

stakeholders at of levels of the telecom industry. We are

extremely thankful with everyone that has contributed to

these achievements, especially our instructors and schools

that have partnered with us throughout this endeavor. As

the world goes through unprecedented times and increasing

reliance on broadband networks and fiber optic

professionals for ensuring continuance of services,

overcoming global challenges, and continue improving our

way of life, the FOA will continue to illuminate the way

by sharing knowledge, skills building, and professional

development opportunities with colleagues and apprentices

from all over the world.

And from Bee and Isaac at 100G:

Want to add your comments? Send them to jim @ foa.org.

|

Technical

On

fiber optic technology, standards, equipment,

installation, etc.

The

FOA Update Page

covers all the new technology and applications we covered

in this newsletter recently. Now you can review all that

new tech at once.

Want

to know more about fiber optics? Study

for FOA certifications? Free

Self-Study Programs are on "Fiber

U®." Looking for specific information? Here's the

largest technical reference on the web: The

FOA Online Fiber Optic Reference Guide.

|

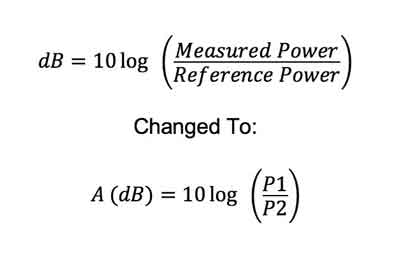

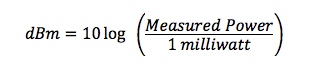

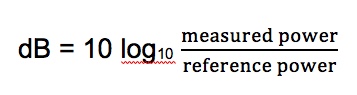

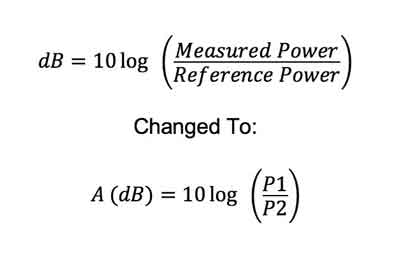

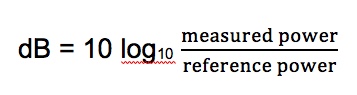

dB

Update - Mystery Solved! 7/2020

Executive

Summary: IEC changed the definition of attenuation

to make it a positive number in defiance of mathematical

and metrological standards, centuries of mathematical

history and common sense.

To

Change The Negative Sign For Loss, Just Change The

Definition! Who Cares If Everybody Else Does It

Differently....

Just

recently FOA was reviewing a new proposed update for FOTP-78

IEC 60793-1-40 Optical Fibres - Part 1-40: Measurement

Methods and Test Procedures - Attenuation. This FOTP might

be the most-referenced FOTP since it deals with measuring

attenuation, something that dozens of FOTPs use in their

testing of components. I started reviewing this document by

skimming the Terms And Definitions, where I was stopped by

Section 3.1 which defined attenuation.

The classic attenuation equation was different.

where (quoting from the standard)

- A

is the attenuation, in dB

- P1

is the optical power traversing cross-section 1 (e.g.

before the attenuation you are measuring - what we

would call the "0dB" reference in testing cables)

- P2

is the optical power traversing cross-section 2. (e.g.

after the attenuation you are measuring - what we

would call the measurement of loss in testing cables)

Note 1

to entry: Attenuation is a measure of the decreasing optical

power in a fibre at a given wavelength. It depends on the

nature and length of the fibre and is also affected by

measurement conditions.

As we traced this definition in other IEC standards, we find

they are variations of this, and one specifically states

that it expresses attenuation as a positive term.

So there you have it - why attenuation is positive - and

therefore gain - like a gainer on an OTDR - is a negative

number. The IEC standards just turned the measurement upside

down - reversing "Measured Power" and "Reference Power" to

get the term to become a positive number in dB when it's

attenuation.

And I might add, they are unique. See References

below. Undoubtedly some instrument manufacturer wanted the

definition that way and had no broad knowledge of

measurement convention. Nor did they understand fiber optic

power meters.

At least now we know where the confusion lies.

Three issues:

First:

There

are several reasons to object to this from a mathematical

and measurement standpoint. When you measure something

against a reference, it's common to divide the measured

value by the reference. Thus if something is getting

smaller, like attenuation, and the change is the measured

value decreases by 50% or half, you expect the ratio of

powers to be a number less than 1 because the value has

decreased, in this case the ration would be 1/2 or 0.5 0r

50%.

Consider what happens when using the equation above. If P1

is the reference and P2 the value after it decreases, the

ratio for the example above would be 2. Wouldn't anybody

assume that the measured value had increased instead of

decreased it the ratio was 2?

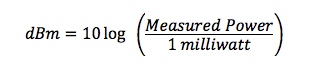

Second:

There are several reasons to object to this from a

mathematical and measurement standpoint. When you measure

something against a reference, it's common to divide the

measured value by the reference - like we do defining dBm

where the reference is 1mw.

We checked and the TIA and IEC standards for measuring

power, FOTP-95, still defines dBm this way. That's good,

because we're used to negative dBm being power smaller than

1mW and positive dBm being power larger than 1mW.

However if one makes an attenuation measurement using a

fiber optic power meter calibrated in dB and you used the

"Zero" control to set the reference,

the resulting measurement of loss will be a negative

number. Likewise if you measure the two powers in dBm,

the resulting measurement of loss will be a negative number,

if you understand negative numbers.

Remember dBm is defined as Power(measured)/Power(1mw) (see

FOTP-95, Sec. 6.2) and if dBm were defined in this

upside down manner, power levels below 1mW would be

positive numbers, not negative as they are now, and power

levels above 1mW would be negative! How's that for

confusing.

Third:

The definition assumes you are making measurements in linear

units - Watts, milliwatts or microwatts, then calculating

dB. Does anyone do that anymore? We don't think so.

Instruments measure in dB and dBm. Recognizing that, some

standards actually tell you how to calculate using simple

subtraction of dB or dBm measurements but reverse the values

so loss is positive and gain negative.

Maybe it's time to drop the definition from the standards or

at least provide descriptions of how one makes measurements

in dB.

References: The method for calculation of attenuation

in dB IEC uses in these fiber optic standards is definitely

not how measurements are normally defined. In fact we looked

at several dozen websites and the result was 100% -

attenuation is a negative value.

Rapid

tables

Wikipedia-

If P is

greater than P0 then LP is positive;

if P is less

than P0 then LP is negative.

Wikipedia

- definitions of the International Systems of Quantities -

If P is

greater than P0 then LP is positive;

if P is less

than P0 then LP is negative

TonTechnik-Rechner

- see Electric Power (telephone)

UC

San Diego Neurophysics - they get it! - (-3dB = half

power)

UC

Santa Cruz - with

the measured value less than the reference, we get a

negative dB value

Henry

Ott Consultants - The unit can be used to express

power gain (P2>P1), or power loss (P2<P1) -- in the

latter case the result will be a negative number.

Electronics

Notes - Where there is a loss, the deciBel equation will

return a negative value

dB

or dBm -Still Confusing 4/2020 -

The

second most missed question on FOA/Fiber U online tests

concerns dB, that strange logarithmic method we use to

measure power in fiber optics (and radio and electronics

and acoustics and more...). We've covered the topic

several times in our Newsletter but there still seems to

be confusion. So we're going to give you a clue to the

answers and hopefully help you understand dB better.

These are all correct statements with the

percentage of test takers who know the answer is correct.

The most answered correctly: dBm is absolute power

relative to 1mw of power (78.8% correct. Does "absolute"

confuse people? It's just "power" but absolute in

contrast to "relative power" which is loss or gain

measured in dB.)

This one is answered correctly less than half the time: dBm

is absolute power like the output of a transmitter.

(41.5% correct, see comment above.)

This one does often get answered correctly: The

difference between 2 measurements in dBm is expressed in

dB. (23.8% correct)

Here is an example of a power meter measuring in dBm and

microwatts (a microwatt is 1/1000th of a milliwatt.)

Here

is an example

of the

conversion of

watts to dBm.

This meter is

reading

25microwatts -

that's

0.025milliwatts.

If we convert

to dBm, it

becomes

-16.0dBm. We

can easily

figure this

out using dB

power ratios.

-10dBm is 1/10

of a milliwatt

or 0.100mW.

-6dB below

that is a

factor of 0.25

so 0.1mW X

0.25 = 0.025mW

or

25microwatts.

The other way

to figure it

is -10dB is

1/10 and -6dB

is 0.25 or

1/4th

(remember 3dB

= 1/2, so 6dB

= 3dB + 3dB =

1/2 X

1/2 = 1/4) so

-16dBm is

1/40milliwatt

or

0.025milliwatts

or

25microwatts.

Read a more

comprehensive explanation of dB here in the FOA

Guide.

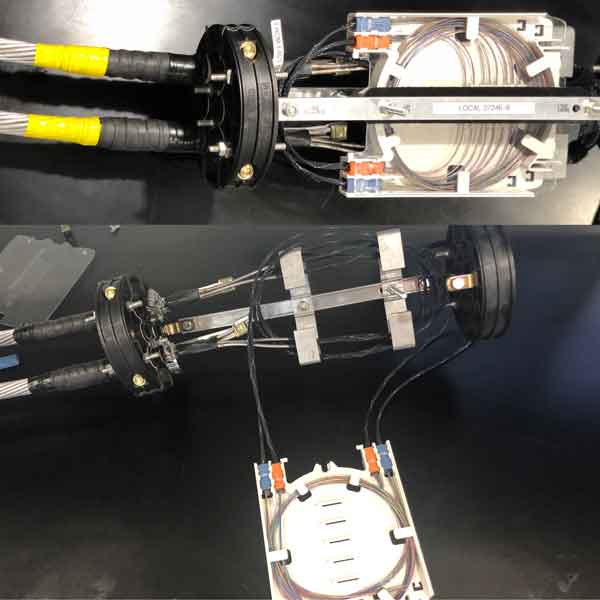

Ever

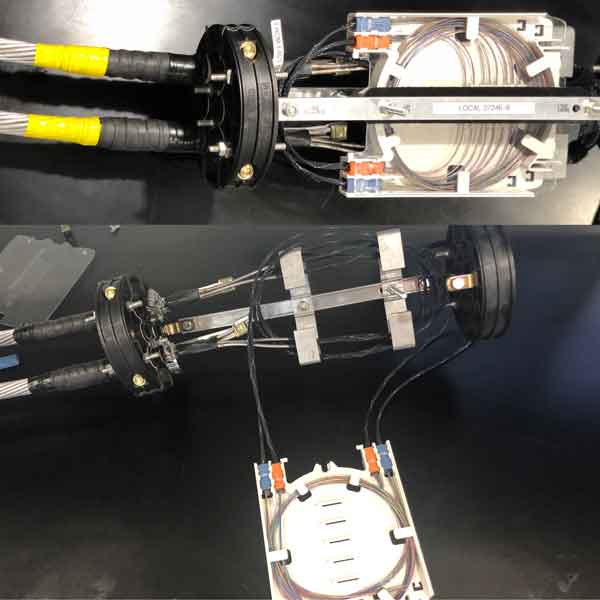

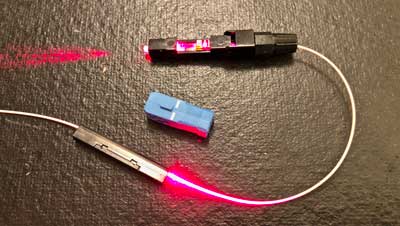

Wonder What Splices For OPGW Look Like?

7/2020

FOA

Instructor and full time installer Jane Bailey sent us this

photo of some recent work splicing OPGW. Very interesting!

Note the incoming cables and the rugged fiber tubes in the

closure.

Splice-On

Connector Manufacturers and Tradenames

7/2020

Eric Pearson shared a list he has researched of prepolished

splice connectors with mechanical splices and SOC -

splice-on connectors for fusion splicing. This list shows

how widepread the availability of these connectors has

become, especially the SOCs and low cost fusion splicers.

Mechanical Splice

1. Corning Unicam® (50, 62.5, SM)

1. FIS Cheetah (???)

2. Panduit OptiCam® (50, 62.5, SM)

3. Commscope Quik II (50, 62.5, SM)

4. Cleerline SSF™ (50, SM)

5. LeGrand/Ortronics Infinium® (50, 62.5,

SM)

6. 3M/Corning CrimpLok (50, 62.5, SM)

7. Leviton FastCam© (50, 62.5, SM)

Fusion Splice

2. Inno (50, 62.5, SM)

3. Corning FuseLite® (50, SM)

4. FORC (50, 62.5, SM)

5. Siemon OptiFuse ™ (SM, MM)

6. Belden OptiMax?? FiberExpress (SM, MM)

7. AFL FuseConnect® (SM, MM)

8. OFS optics EZ!Fuse ™ (50, 62.5, SM)

9. Sumitomo Lynx2 Custom Fit® (50, 62.5,

SM)

10. Commscope Quik-Fuse (50, SM)

11. Ilsintech Pro, Swift® (50, 62.5, SM)

12. LeGrand/Ortronics Infinium® (50, 62.5,

SM)

13. Greenlee (50, 62.5, SM)

14. Hubbell Pro (50, SM)

15. Easysplicer (SM)

Note: There are additional manufacturers from the Peoples

Republic of China, which advertise on Amazon and eBay.

The

Times They Are A Changin' (fiber optics, that is) 6/2020

(With

kudos to Bob Dylan who is releasing

a new album this month at the young age of 79!)

What we mean by that title is that in technology things

change. In recent times we've seen a lot of change in fiber

optics and recent standards meetings and discussions with

some of the FOA technical advisors have amplified some of

these changes, as we report here, such as the issue of

mulimode vs singlemode fiber above and the topics below.

Connectors: Nobody ever wanted to polish fiber optic

connectors in the field - ever - and that only worked with

multimode fiber anyway - singlemode polishing was too

critical to be done in the field. Long ago, factory made

terminations with a mechanical splice in the back of the

ferrule became available. We called them prepolished/splice

connectors. But they were tricky. The secret to a good

termination was a good cleave and good cleavers were

expensive.

Over time, better termination kits made the connectors lower

loss and easier to install. Now the inexpensive cleavers

reviewed above make these connectors work better, but the

combination of a connector and a mechanical splice mean they

are still expensive. And mechanical splices generally work

better with multimode fiber than singlemode fiber.

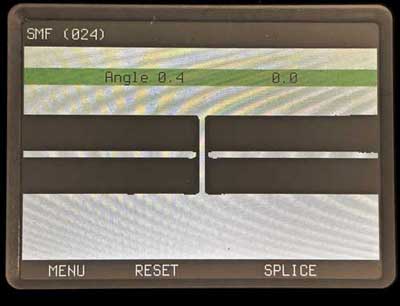

More recently, fusion splice-on connectors (SOCs) have

become available. Instead of a connector plus mechanical

splice, you have a connector with a pigtail that you fusion

splice on to a fiber to terminate it. Eliminating the

mechanical splice reduces the cost considerably. The fusion

splicer has also become much less expensive also, making

this a very popular choice for singlemode fiber where you

must have a fusion splicer anyway. They are available for

multimode and singlemode, but the big price advantage is

with singlemode.

Testing Multimode Fiber and Bend-Insensitive Fiber: A

decade ago when bend-insensitive multimode fiber (BI MMF)

first became available, it was not well understood. Since

this was the era of the adoption of "encircled flux" as a

new method of specifying mode control for MM testing, the

unknown effects of BI fiber on modes was not well

understood. As a result, BI MMF was prohibited for use

in reference test cables when testing, even if testing BI

MMF in most standards for testing. That prohibition made

little sense since no fibers were marked as BI or non-BI and

since most MM fiber was BI, finding non-BI fiber for test

cables was problematic. And nobody really knew about this

issue anyway.

FOA has been asking questions about this issue regularly in

standards committees. At a TIA meeting held online recently,

Fluke presented data that showed only minor differences

between tests made with reference test cables with regular

(non-BI) and BI MMF. This realization is making its

way through standards committees now, so this issue is going

away.

OLTS vs OTDR Testing: This is a bit of a bigger issue

than the one above and the subject of many discussions and

articles over the years. In recent discussions with Eric

Pearson and some other FOA advisors covering the OLTS/OTDR

issue as well as the issue of loss budgets, the consensus

was this should not be a issue, either OLTS or OTDR data

should be acceptable if the testing is done properly.

"Done properly" means OTDR testing uses both a launch and a

receive reference cable, meaning it is not a single-ended

test.

Understanding the combined measurement uncertainty has made

this a non-issue. For multimode fiber, the total loss of a

typical link is only 2-3dB since premises cabling networks

are short and multimode fiber loss is lower than in the past

- nearer 2dB/km than 3dB/km on modern fibers. The

uncertainty of such low loss measurement with either

instrument is small enough that either measurement will give

a good indication of the quality of the fiber. The same is

true for premises SM fiber in a data center or passive

optical LAN.

The same is true for OSP singlemode fiber where the OTDR

loss measurement is going to be made anyway to verify

splices on concatenated cables. Longer cables are probably

be tested for fiber characterization also, so lots of data

will be available for judging the condition of individual

fibers.

Eric Pearson makes another good point. His experience is

that fibers are either good or bad, usually really bad, not

just slightly so. If the tech doing the testing has good

cleaning discipline, the connectors are cleaned and

inspected, so a failure might be a poorly installed

prepolished/splice connector, and that's likely to be quite

bad. If the connectors are field-polished on multimode

fiber, careful inspection is extremely important to insure

connectors were installed properly.

We'll finish with Eric's conclusion: And if reasonable care

is taken, both LSPM/OLTS and OTDR tests will give “useful"

results. The purpose of measurements is to accept or reject

the installed products. With that understanding, the

explanations of the subtleties are not critical to the

installers, for whom I write. That being said, the key

qualifier is 'if reasonable care'

Conclusion: Technology changes but one thing does

not. With all the topics above, the results are all

dependent on the knowledge and skill of the technician.

Experienced technicians need to stay up to date and novices

need to be trained correctly. That's the focus of the FOA.

When founded almost 25 years ago - next month is our

anniversary - the charter was to "Promote professionalism in

fiber optics through education, certification and

standards." Still is.

But then, another mystery shows up: Eric

Pearson brought up a new issue with standards. This

concerns the use of a singlemode mode filter; a small loop

to remove higher order modes from singlemode fiber for

testing. When a laser source launches into a

singlemode fiber, the fiber may carry more than one mode for

a short distance, say up to 100m. To prevent this affecting

measurements, standards have generally specified a mode

filter in the launch cable created with a small loop in the

fiber, around 30mm.

Back in the 90s, the standards had a 2” loop and referenced

FOTP-77. FOTP-77 was allowed to expire in 2003 and sometime

later the loop became 30mm/1.3”. Now it seems to have

disappeared from some international standards (Eric says IEC

61280-4-2 has no requirement for the loop) but remains in

some US standards like FOTP-171, sec 3.3. Phil Irwin of

Panduit, head of the TIA TR42.11 standards committee, noted

that FOTP-34, the standard for measuring components loss,

e.g. connectors, and FOTP-171B (patchcords) include this

mode filter before and after the component under test.

Another topic for another time. We will continue

investigating this.

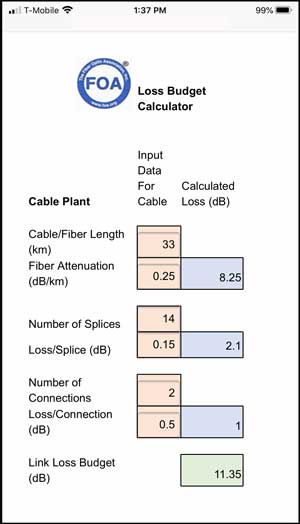

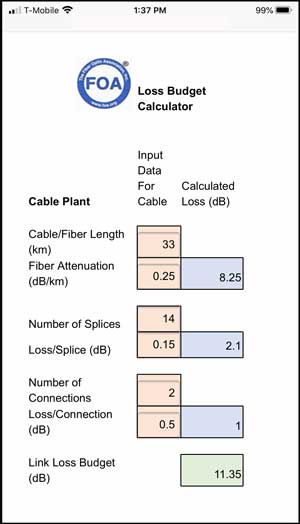

FOA

Loss Budget Calculator On A Web Page 5/2020

FOA has

written many articles about loss budgets, something everyone

involved in fiber optics needs to know and needs to know how

to calculate. We recently discovered how to get a

spreadsheet ported to a Web page, so we created this web

page that calculates loss budgets. We have an iOS loss

budget app, but with this web page, you can calculate loss

budgets from any device, smart phone, tablet, laptop, or

desktop computer that has web browsing capability.

Bookmark this page (especially on your smartphone): FOA

Loss Budget Calculator Online

|

Eric Pearson teaches a class at Fiber U 1994 in Long Beach,

CA

Eric Pearson teaches a class at Fiber U 1994 in Long Beach,

CA Dan Silver (R) of 3M demonstrates how to dress cables in a

splice closure at Fiber U 1994 in Long Beach (more

Fiber U photos)

Dan Silver (R) of 3M demonstrates how to dress cables in a

splice closure at Fiber U 1994 in Long Beach (more

Fiber U photos) FOA website ca. 2000 (view

here on the WayBack Machine Internet Archive)

FOA website ca. 2000 (view

here on the WayBack Machine Internet Archive)

FOA

Advisors Meeting in 1997.

FOA

Advisors Meeting in 1997.

John Highhouse

conducts class at FOA TTT 2002

John Highhouse

conducts class at FOA TTT 2002

Bob Ballard

of BDI Datalynk and one of his classes

Bob Ballard

of BDI Datalynk and one of his classes Joe

Botha of Triple Play in his element, teaching in Zambia

Joe

Botha of Triple Play in his element, teaching in Zambia Ian Gordon Fudge of Fiber DK teaching students how to splice

OPGW in Greenland. Ian and FOA Director and Canadian Bill

Graham have a friendly competition to see who has trained

more places in the far North.

Ian Gordon Fudge of Fiber DK teaching students how to splice

OPGW in Greenland. Ian and FOA Director and Canadian Bill

Graham have a friendly competition to see who has trained

more places in the far North.  Bee

Suat Lim, Director (R) and Isaac Yeo Hock Lai (L) of 100G in

Singapore with Karen and Jim of the FOA during a visit to SE

Asia. Bee was instrumental in creating the FOA textbook on

Fiber Optic Network Design and training techs in SE

Asia.

Bee

Suat Lim, Director (R) and Isaac Yeo Hock Lai (L) of 100G in

Singapore with Karen and Jim of the FOA during a visit to SE

Asia. Bee was instrumental in creating the FOA textbook on

Fiber Optic Network Design and training techs in SE

Asia.  Jerry Morla, 2nd

from R, at a meeting of FOA instructors in Atlanta, is the

latest FOA Director to join us. Jerry, who came on board in

2008, is FOA's ed-tech person, looking at new methods using

technology to make learning better and more efficient, a

valuable asset in these times of social distancing and

isolation.

Jerry Morla, 2nd

from R, at a meeting of FOA instructors in Atlanta, is the

latest FOA Director to join us. Jerry, who came on board in

2008, is FOA's ed-tech person, looking at new methods using

technology to make learning better and more efficient, a

valuable asset in these times of social distancing and