The

Fiber Optic Association

- Tech Topics

Making

Optical Fiber

Students

often ask how fiber is

made. It's certainly not obvious how something only 1/8 of a mm

- 0.005 inches - in diameter can be made with such precison.

Some basic facts about how optical fiber is manufactured may help

to provide a better understanding of how optical fiber works too.

At

the Core

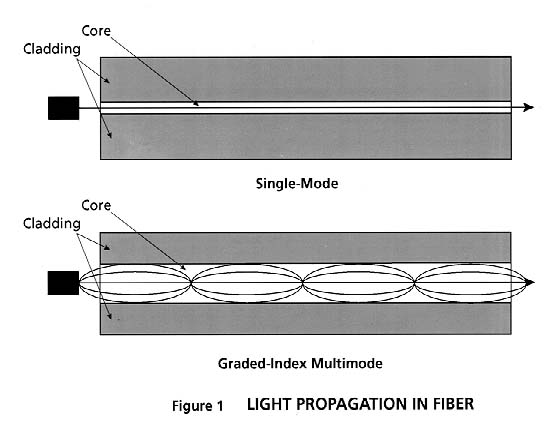

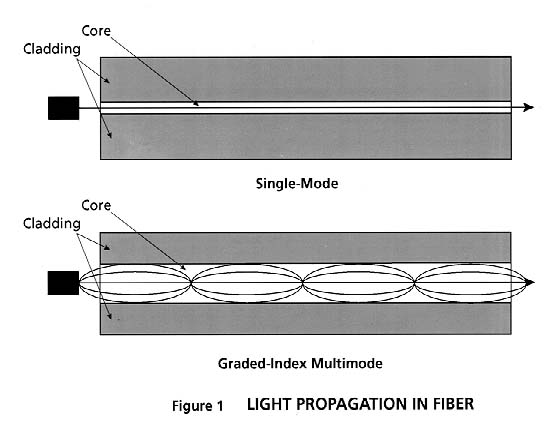

As you know, there are two main types of optical fiber: single-mode

and multimode. Both types of fiber are composed of only two basic

concentric glass structures: the core, which carries the light

signals, and the cladding, which traps the light in the core (Fig.

1).

Single-mode

fiber has a smaller

core -- only 9 microns in diameter - and only 6 times the wavelength

of light it transmits. The small core size limits the transmitted

light in the fiber to only one principle mode, which minimizes

dispersion of light pulses, increasing the distance the signal

can be sent.

Multimode

fiber has a large core

diameter compared to the wavelength of the transmitted light 50

or 62.5 microns. Therefore, multimode fiber propagates more than

one mode of light. With its relatively large core, multimode fiber

suffers more dispersion than singlemode. Using a graded index

core, where layers of light have lower index of refraction as

you go further from the center of the core, minimizes dispersion

but complicates the manufacturing process.

There are two

main steps in the

process of converting raw materials into optical fiber ready to

be shipped:

1. manufacturing of the pure glass preform and 2. drawing of the

preform

Manufacturing

The Preform

The first

step in manufacturing

glass optical fibers is to make a solid glass rod, known as a

preform. Ultra-pure chemicals -- primarily silicon tetrachloride

(SiCl4) and germanium tetrachloride (GeCl4) -- are converted into

glass during preform manufacturing. These chemicals are used in

varying proportions to fabricate the core regions for the different

types of preforms.

The basic

chemical reaction of

manufacturing optical glass is:

SiCl4 (gas) +

O2 > SiO2 (solid)

+ 2Cl2 (in the presence of heat)

GeCl4 (gas) +

O2 > GeO2 (solid)

+ 2Cl2 (in the presence of heat)

The core

composition of all standard

communication fibers consists primarily of silica, with varying

amounts of germania added to increase the fiber's refractive index

to the desired level. Single-mode fibers typically have only small

amounts of germania and have a uniform composition within the

core. Multimode fibers typically have a much higher refractive

index, and therefore much higher germania content. Also, the core

composition and the refractive index of graded-index multimode

fibers changes across the core of the fiber to give the refractive

index a parabolic shape.

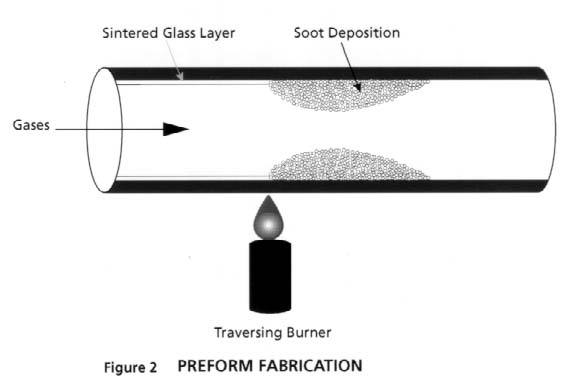

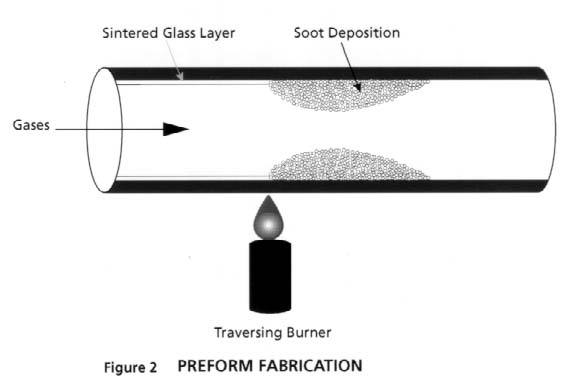

There are

several methods used

to manufacture preforms. In the Modified Chemical Vapor Deposition

(MCVD) process, the highly controlled mixture of chemicals described

above is passed through the inside of a rotating glass tube made

of pure synthetic SiO2.

The pure silica tube is mounted on a lathe equipped with a special

heat torch. As the gasses flow inside the tube, they react to

the heat by forming solid submicron particles, called "soot,"

in the vicinity of the heat zone. Once the soot is formed, it

is deposited on the inner wall of the tube. As the burner traverses

over the deposited soot, the heat transforms these solid white

particles into pure, transparent glass, in a process called

vitrification.

The deposited material will form the core region of the optical

fiber( see Fig. 2 for a schematic diagram of the process.)

.

The process

is repeated for many

hours as each subsequent core layer is formed. For every sweep

of the burner, the manufacturer can modify the composition, viscosity

and thickness of the deposited layer in order to produce specific

fiber designs. This, in conjunction with the ability to change

the speed at which the burner moves and the temperature of the

flame, gives us the ability to manufacture a wide range of ultra-pure

optical fiber types.

The precise

delivery of chemicals

is ensured through the design of manufacturing equipment that

performs accurately and consistently. For example, mass flow

controllers

are used to meter chemicals for the reaction. All critical process

parameters are monitored and controlled in real time by on-line

computers that are also programmed to collect all pertinent process

data.

After the

desired amount of core

material is deposited the chemical flow is eliminated, the speed

of the torch is decreased and the temperature of the flame is

increased so that the tube collapses into a solid rod. At the

end of this process, an operator separates the preform from the

rest of the glass assembly and moves it to the next step. The

entire preform manufacturing process is highly automated with

minimal human involvement.

The

refractive index of the manufactured

preform is measured using a preform analyzer. This instrument

measures critical core parameters and compares them to internal

specifications. All pertinent parameters are plotted automatically

on statistical control charts that the operators review for every

measurement.

The pure

silica glass starting

tube has become part of the cladding region of the preform. The

cladding region is further increased by the "sleeving"

or "overcollapse" process. Here, another pure silica

tube is collapsed on the outside of the original preform, bringing

the geometrical dimensions of the preform to final specifications.

Another

process used is Outside

Vapor Deposition (OVD), where the soot is deposited on the surface

of a "bait rod" made of pure silica. The first layers

are the core then the cladding is added. After all the layers

are deposited, the bait rod is removed and the preform is headed

and collapsed in a similar way to the MCVD process.

Drawing

The Fiber

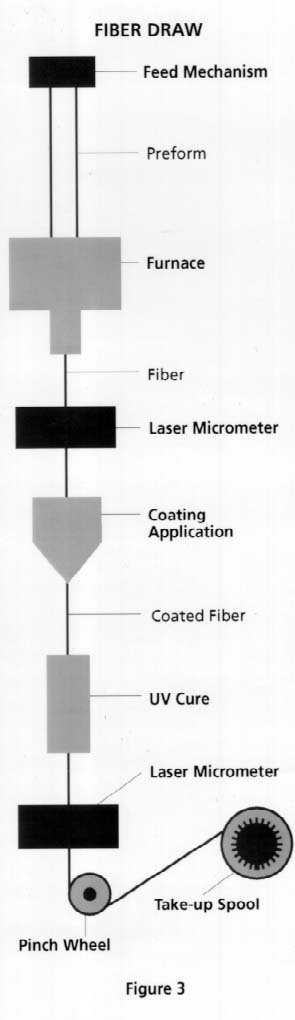

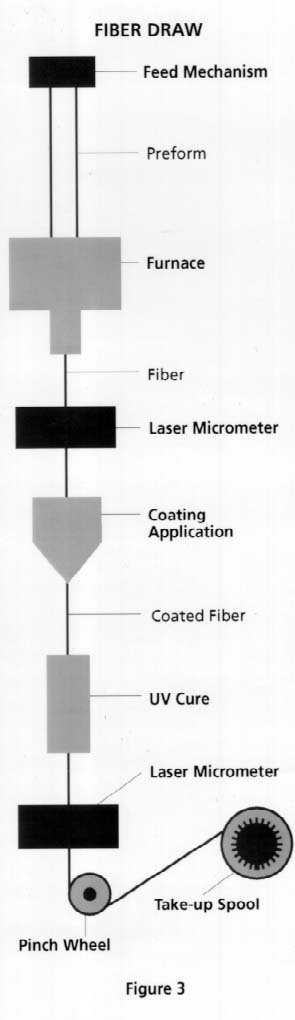

The next step

in the process of

producing optical fibers is to convert the manufactured preform

into a hair-thin fiber. This is done in an operation called fiber

draw (Fig. 3). The tip of the preform is lowered into a high-purity

graphite furnace. Pure gasses are injected into the furnace to

provide a clean and conductive atmosphere. In the furnace, tightly

controlled temperatures approaching 1900°C soften the tip

of the preform. Once the softening point of the preform tip is

reached, gravity takes over and allows a molten gob to "free

fall" until it has been stretched into a thin strand.

The operator

threads this strand

of fiber through a series of coating dies, and the drawing process

begins. The fiber is pulled by a tractor belt situated at the

bottom of the draw tower and then wound on winding drums. During

the draw, the preform is heated at the optimum temperature to

achieve an ideal drawing tension. Draw speeds of 10 - 20 meters

per second are not uncommon in the industry.

During the

draw process the diameter

of the drawn fiber is controlled to 125 microns within a tolerance

of only 1 micron. A laser-based diameter gauge is used to monitor

the diameter of the fiber. The gauge can sample the diameter of

the fiber at rates in excess of 750 times per second. The actual

value of the diameter is compared to the 125 micron target. Slight

deviations from the target are converted to changes in draw speeds

and fed to the tractor mechanism for correction. If the diameter

of the fiber increases above its target, the drawing speed is

increased; if the fiber diameter starts falling below the target,

the draw speed is decreased. Typically, 125 micron diameter control

is achieved within a six sigma interval of the 1 micron tolerance.

A two layer

protective coating

is then applied to the fiber -- a soft inner coating and a hard

outer coating. This two-part protective jacket provides mechanical

protection for handling while also protecting the pristine surface

of the fiber from harsh environments. These coatings are cured

by ultraviolet lamps. The drawing process is well automated and

requires virtually no operator interaction after the threading

step.

Test

and Measurement

The drawn

fiber is next tested,

where all optical and geometrical parameters are checked to ensure

that they meet stringent requirements.

First, the

tensile strength of

the fiber is tested. Each spool of drawn fiber is wound through

a series of capstans and subjected to loads to ensure that the

fiber has the minimal tensile strength specified. The fiber is

then spooled onto shipping reels and cut to specified lengths.

The fiber is

tested for point

defects with an Optical Time Domain Reflectometer (OTDR), which

uses scattered light to indicate the location of any anomalies

along the length of the fiber.

The spooled

fiber is automatically

tested for transmission paramters including:

- attenuation:

decrease in signal strength over distance

- bandwidth:

information-carrying capacity; an important measurement for multimode

fiber

- numerical

aperture: the measurement of the light acceptance angle of a fiber

- cut-off

wavelength: in single-mode fiber the wavelength above which only a

single mode propagates

- mode

field diameter: in single-mode fiber the radial width of the light

pulse in the fiber; important for interconnecting

- chromatic

dispersion: the spreading of pulses of light due to rays of different

wavelengths traveling at different speeds through the core; in

single-mode fiber this is the limiting factor for information carrying

capacity

In addition,

both multimode and

single-mode fibers are measured for many geometrical parameters

including:

- cladding

diameter

- cladding

non-circularity

- coating

outer diameter

- coating

outer non-circularity

- coating

concentricity error

- core-clad

concentricity error

- core

non-circularity

- core

diameter

Environmental

and mechanical testing

is also performed periodically to ensure that the product maintains

its optical and mechanical integrity and complies with customer

requirements. These tests include:

- coating

strip force

- operating

temperature range

- temperature

dependence of attenuation

- temperature-humidity

cycling

- accelerated

aging

- water

immersion

Finally, the

tested fiber is ready

for cabling to protect the fiber and then installation.

Thanks

for information and

photos to

O F S, formerly

Lucent Technologies, which manufactures and markets high-performance

multimode optical fibers for data communication applications worldwide.

Visit O F S's Web site at http://www.ofsinnovations.com/

Return To The

FOA

Home Page

Return To FOA

Tech Topics