FTTA - Fiber

To The Antenna

Today's users of

mobile devices depend on wireless connections for their

voice, data and even video communications. Even homes and

businesses may depend on wireless, especially those who

are not in urban or suburban areas served by FTTH (fiber

to the home) or FTTC (fiber to the curb.) Some of us in

the business now use the term FTTW for fiber to wireless,

since wireless depends on fiber for the communications

backbone and increasingly the connection to the wireless

antennas, no matter what kinds of wireless we use.

Wireless is not entirely wireless. The easiest way to

understand wireless is to think of it as a link that

replaces the cable that connects your cellular or wireless

phone to the phone system or the patchcord that

connects your computer or other portable Internet device

to the network. To understand wireless, it is necessary to

look at several different and unique types of wireless

systems, including cellular wireless phones, wireless in

premises cabling, municipal or private wireless links and

even some of the short distance links used for computer

peripheral connections.

This FOA page focuses on fiber to the antenna, primarily

looking at cell towers, but also antennas mounted on

rooftops, small cells and distributed antenna systems

(DAS.) Because of its variety, DAS will be covered in a

separate page in more detail.

Why fiber to the antenna?

The reason fiber is being used to connect towers and then

go up the tower to connect the antennas is consumers

insatiable desire for bandwidth. To accommodate more

bandwidth in the cellular systems, new cellular protocols

being are used (4G, LTE, and whatever comes next) but also

more antennas are needed to support more frequencies. Thus

cell towers that once had 3 antennas for coverage may have

two dozen antennas.

The increased demand for cellular bandwidth to support

fast growing data usage from smartphones and tablets

requires upgrading towers – more bandwidth means more

antennas. More antennas means more cables up the towers.

If those cables are coax, it means more weight and wind

resistance, perhaps more than the tower was designed for.

And RF (radio frequency) signals require lots of power to

transmit up the tower since the coax cable attenuates the

signals at high frequencies.

Today’s cell towers are being modified to replace older

copper coax cables with fiber optic cables to reduce

weight and cost. Like other applications of fiber, the

small size and light weight allows one fiber cable (which

often includes power conductors also) to replace many coax

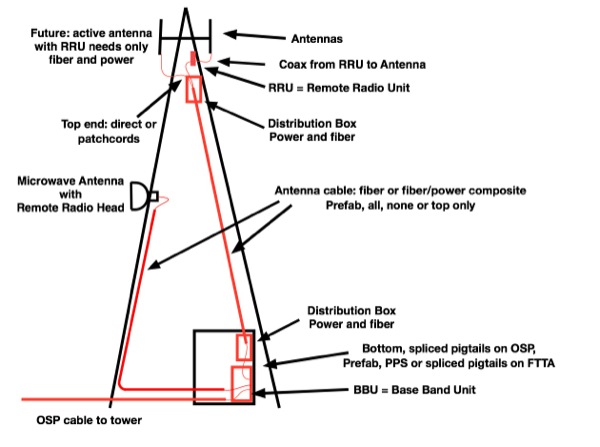

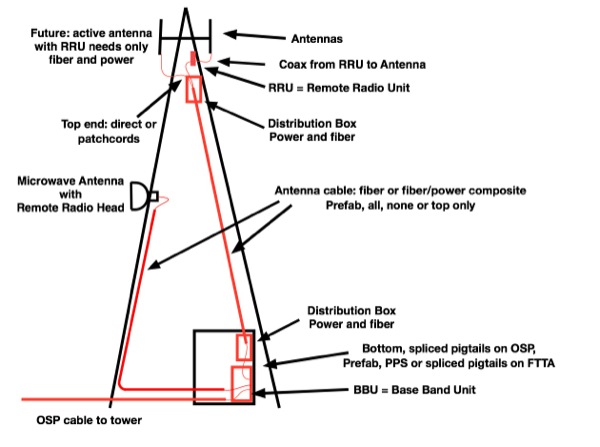

cables. This diagram shows what a current cell tower looks

like. The diagram is way too complicated for a quick view

so we’ll focus on various areas of the tower to show how

fiber is used, then we’ll go into issues of installation

and testing.

Cellular Wireless

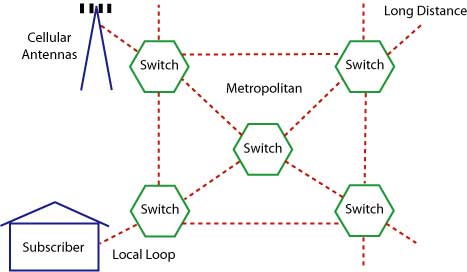

Cellular phone systems have grown to dominate the

telecommunications marketplace. Countries that have had

extensive landline phone systems for a century now already

have more cell phones than land lines. Countries that had

not developed landline-based phone networks skipped them

entirely and went directly to cellular wireless where the

adoption rates have been extremely high.

While cellular wireless started out as a voice network,

text messaging became very popular, eclipsing voice for

most users. Smart phones brought the Internet to the

phone, and soon data became the largest traffic generator

for cellular networks. In the first 3-1/2 years of the

iPhone, AT&T claimed their data traffic grew 8000% -

80 times! Now video is coming to these same devices,

creating an even faster growth rate for cellular network

traffic.

To

accommodate this traffic level, wireless needs new systems

with more radio frequency spectrum. Current systems (CDMA

for some systems, in the US, GSM for the rest of the US

and the world) are evolving into new generations of

systems (4G, LTE) that have more data bandwidth.

Almost from the beginning, cellular towers were connected

to the telco networks over fiber optics, just like any

other connection. Wireless towers have small huts at

the base that connect to fiber backbones that connect

towers to the various phone companies. As traffic grows,

towers need more antennas. Instead of 3-4 antennas on a

tower, now one sees dozens, so towers and buildings now

look like this:

or on buildings.

All these

antennas on a tower or the side of a building have created

another problem. In the past, each antenna has been

connected by a large (~2", 50mm) coax cable that carries

both signal and power to the antenna. But with all these

antennas, the size, weight and even wind resistance of

these cables has become a big problem, as has the cost.

These towers which have been upgraded to add many antennas

show the problem with these large coax cables.

This is

another application where copper cable is being replaced

by optical fiber. One small fiber cable can replace all

those coax cables and a separate power cable is used for

the drivers on the antennas. These applications use mostly

prefab

cable assemblies since making terminations on top of

the tower is difficult to say the least. Some applications

use prefab at the top of the tower and conventional

termination at the base. Many of these systems use

multimode fiber because the distances are so short and the

transceivers are much less expensive for MM fiber.

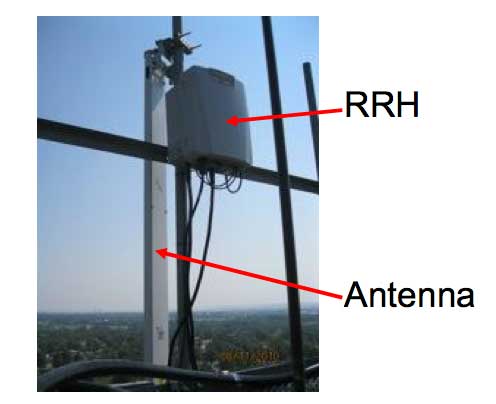

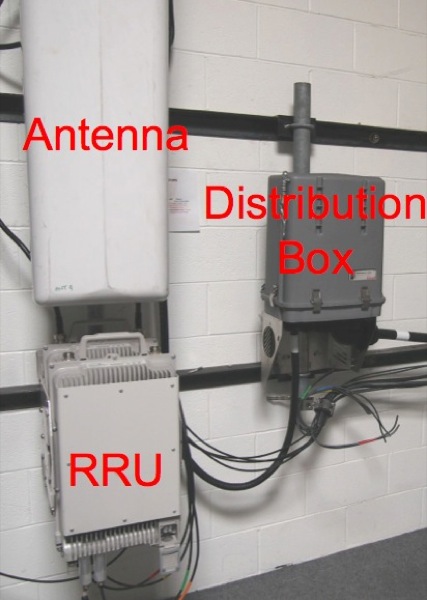

Below are

photos from Corning showing a remote antenna head end and

antenna and the fiber terminal serving the antennas. Note

the use of a prefab cable system at the top of the tower,

making installation much easier. Some installations use a

composite cable that includes both fiber and power

conductors so only one cable need be installed up the

tower.

Photos courtesy of Corning.

Many cell

towers are independently owned and space for antennas is

rented to the service providers. Installation of fiber to

the towers and fiber up to the antennas is generally done

by independent contractors who specialize in this kind of

work.

Another Option - Small

Cells

Small cells go by

many names including micro-cells. They are small

integrated radios and antennas intended for small

geographic areas. They can cover the range of 700MHz to

2.6GHz with power outputs from 1-5W, much less than

regular cellular antennas. They are intended to be be

mounted on typical urban fixtures – walls, street lights,

traffic lights, bus stops, whatever gets them slightly up

off the ground.

Alcatel-Lucent LightCube Radio Small Cell

Because they cover smaller areas than regular cellular

antennas, they will have fewer users connecting, spreading

out available bandwidth to increase bandwidth available

per user. Most will require only a single SM fiber and DC

power making installation easy where municipal cable

plants are available. Fiber technology for installations

is standard OSP and premises – nothing new required. We

understand they can even use PON technology to reduce the

electronics near the antenna. You can place several of

these small cells in one dome providing extended coverage

over many frequencies.

Distributed

Antenna Systems (DAS)

Distributed antenna systems (DAS) have many uses,

from providing coverage in dead zones like inside large

office buildings or campuses. They are also used in

facilities that have large crowds expecting cellular

(and wireless) services where the density of antennas is

high but the power requirements are low.

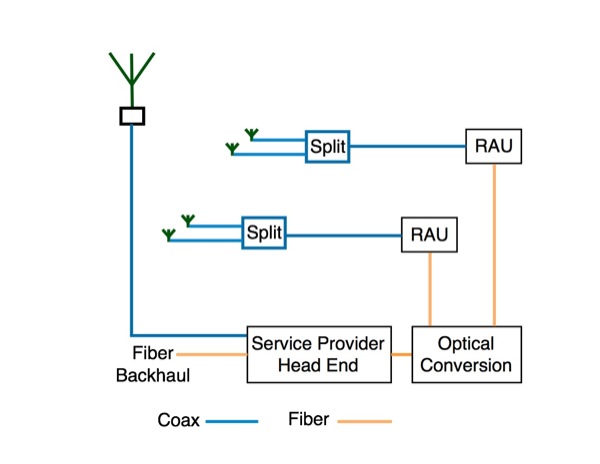

DAS diagram - typical application

Indoor DAS Antenna and Remote Radio Unit (KLA Labs)

A DAS has to connect to service providers which is done

with fiber backhaul to all the service providers for

large facilities and may be done by wireless for smaller

facilities. Connections inside the facility will

generally be done with singlemode fiber following

standard premises cabling installation practices to the

remote antenna units (RAU) which can drive several

antennas even through coax splitters.

The block diagram here is generic – practically every

manufacturer of DAS systems has different names for the

various operational blocks and some include unique

architectures, even using PONs (passive optical

networks) like OLANs and FTTH. But the idea is to get

wireless signals to numerous remote antennas over fiber,

convert to coax at remote antenna units (RAU) and then

distribute to numerous low-power antennas, often

multiples through coax splitters, covering small areas.

Fiber To The Tower

In a cell tower, the cellular antennas connect to users'

mobile devices, but all those communications devices must

connect into the public telephone networks. The older

towers connected on copper phone lines just like many

landline subscribers still have for their phone

connections. However older copper wires do not have

adequate bandwidth for modern mobile devices like

smartphones or tablets that consume vast amounts of

digital data.

Thus most towers are being connected on fiber that offers

virtually unlimited bandwidth. In remote areas, where

installing fiber optic cables can be expensive, microwave

links are often used. The microwave links are more cost

effective for remote towers and their limited bandwidth

compared to fiber optics may not be as big a problem since

remote towers generally have fewer users than those in

urban or suburban areas.

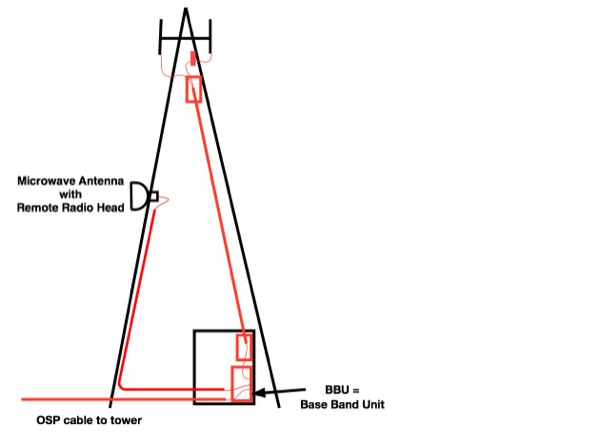

Connections to the cell tower

The installation of an OSP fiber optic cable is

conventional, underground, direct buried or aerial to the

tower and terminated at the base using the hardware for

the BBU. The crew doing the OSP cable install may be

different than the one doing the tower work because the

OSP crew may use different equipment and procedures than

the FTTA installation.

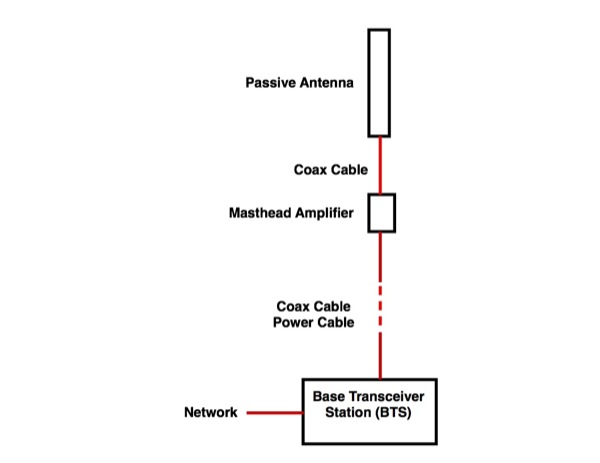

Connecting To Antennas

Traditional cell towers (below) use copper coax cables.

The network feed goes into a base transceiver which drives

analog signals up the tower to a masthead amplifier which

is connected by a short coax cable to a passive antenna.

Coax has high attenuation so the final antenna drive amp

is needed to provide adequate signal to drive the antenna.

The base transceiver station has interfaces for either a

digital telephone network over cable, usually fiber, or a

microwave antenna feed.

Traditional coax link to antennas

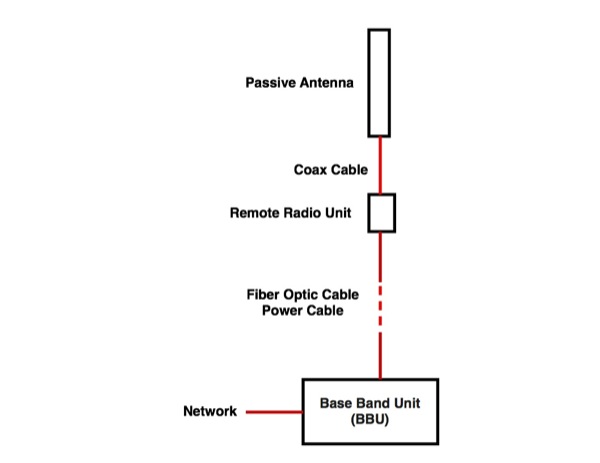

Today’s towers are moving to a digital system based on

fiber optic cable to a remote radio unit (RRU, sometimes

called RRH for remote radio head) that converts the

digital signal to analog and drives the passive antenna

over copper coax cable. Cables up the tower have fiber and

electrical conductors, usually inside an armored jacket.

The base band unit (BBU) connects to the telecom network,

either by a fiber optic cable or sometimes a microwave

antenna.

Today’s tower diagram-This is the most common system in

use now so we will focus on it.

Many systems use a digital communications standard called

CPRI - The Common Public Radio Interface –to connect the

BBU and RRU. CPRI is an industry cooperation aimed at

defining a publicly available specification for the key

internal interface of radio base stations between the

Radio Equipment Control (REC) and the Radio Equipment

(RE). The parties cooperating to define the specification

are Ericsson AB, Huawei Technologies Co. Ltd, NEC

Corporation, Alcatel-Lucent and Nokia Siemens Networks.

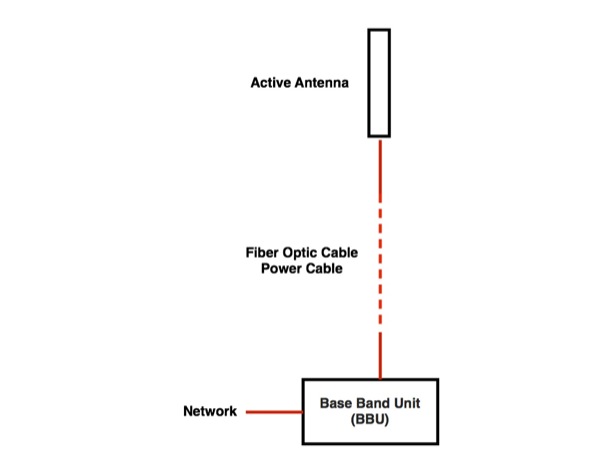

Active antenna system

Active antennas are the newest technology

and are beginning to be installed in new systems. The

antenna is an active device with the RRU integrated into

the antenna. Some towers are already being fitted with

antennas like this (2014). With an active antenna one only

needs a fiber/copper cable to bring digital signals

directly from the BBU and power the antenna.

Typical Tower Diagram

Cables up the tower have fiber and electrical conductors,

usually inside an armored jacket. The top of the tower may

have a fiber/copper distribution box that connects the

RRUs. There are usually 3 RRUs for the 3 antenna systems

aimed for full wireless coverage. Some systems use one

cable to feed all 3 antennas so a distribution box is used

to break out the main cable to 3 cables for each RRU. If 3

cables are used, one for each RRU, the distribution box

may not be used. Smaller fiber-only distribution boxes are

also available. The RRUs have fiber and copper power

inputs from the BBU below and coax going out to the

antennas, either one or two cables depending on the

antenna. Various suppliers may partition the equipment at

the top of the tower differently but the functions

generally follow this diagram.

FTTA tower diagram

Cables

are often prefab assemblies, terminated in a factory to

the proper length and shipped on large spools for safe

transport. Typical

FTTA cable has both fiber and copper power conductors in

one cable, often with armor under the jacket for

protection. The fibers may be either singlemode or

multimode fiber depending on the electronics. Connectors

are usually duplex LC types chosen for their small size.

The main issues for installers are to make certain the

fiber optic cables are protected and not damaged during

installation.

Cable on spool

This cable has 12 fibers for 6 links plus three power

conductors

Here

you can see the individual fiber optic cables and copper

conductors exiting the cable’s armored jacket and the

rugged sealed fitting on the cable for the distribution

box. The individual cable breakouts and their duplex fiber

optic connectors should be handled carefully to prevent

damage or contamination from dirt. Some cables that plug

directly into equipment use LCs in a ruggedized sealed

housing.

Another alternative for cabling is to use these cables

(below) with rugged outlet boxes adapted from aerial

cables used for FTTH – fiber to the home. The connections

are sealed with o-rings for reliability and mate to duplex

patchcords. This alternative is easy to install,

lightweight and rugged, but may not include the power

which must be handled separately.

FTTA cables may have either multimode (MM) or singlemode

(SM) fiber depending on the fiber requirements of the

BBU/RRU units specified. MM fiber has a larger core than

SM so is somewhat more forgiving for cleanliness but both

must be handled carefully and and cleaned thoroughly

before use.

Installing Cables

As you can see from the cable on the spool above, these

cables are not lightweight, especially since they must be

pulled up to the top of cell towers which may be as high

as 300 feet (100m.) A crane or winch is needed to raise

the cable to the top and hold it while it is secured. In

this photo (provided by Corning) the cable is being

winched up along with a bucket holding the accessories

needed to secure and connect it.

Pulling cable up the tower (Corning photo)

Installers must use a winch or crane to get the cable up

the tower. If the cable is armored, a kellum’s grip can be

used to hold it, or a pulling loop may be provided. The

cable is secured to the tower with appropriate fasteners.

Tower Hardware

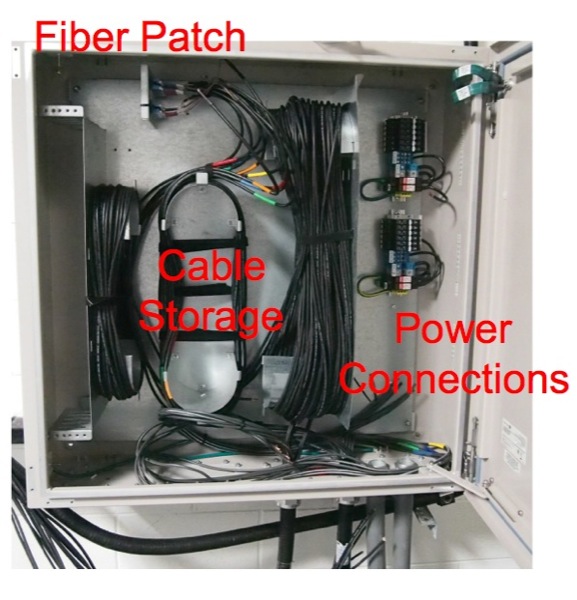

Below

is an example of the equipment for a tower as used in

the training lab of Wireless Workforce (http://thewirelessworkforce.com).

The top distribution box has a patch panel for the fiber

to break out to three RRUs. It also includes a copper

breakout with lightning surge protection. The lower

distribution box also handles both fiber and copper

connections but is bigger to allow for storage for

excess cable. If the cable is too long, the corrugated

jacket can be stripped and the excess fiber stored in

the box. Copper conductors can be cut to length. The

distribution boxes also have provision for grounding and

bonding the corrugated metal armor of the cable.

Equipment at the top of the tower

The top distribution box has a small fiber patch panel

to connect patchcords from the RRU to the cable coming

up the tower. It also has power connections for the

equipment and lighting surge protectors.

At the bottom of the tower, another distribution box

handles both fiber and copper power connections and

provides storage for excess fiber optic cable.

Patchcords connect from here to the BBU.

Rooftop Installations

Rooftop installations require permission from the building

owner and the installation designer will work with the

owner on the location of antennas (some do not allow

external mounting like this) and negotiate on how the RRUs

and BBUs will get installed, as well as how the fiber and

power will be routed to the equipment on the roof. It’s

not unusual to install cable trays or conduit for the

cables on the roof to keep them organized and make them

look more attractive.

Antennas on building

Note the different types of mountings on the antennas on

this building, likely from different carriers on the same

building.

Rooftop installation (RFS Hybriflex)

It’s hard to generalize about rooftop installations as it

depends on the building structure, location of the

entrance facility in the building and number of service

providers using the building. Most buildings will have the

BBU somewhere downstairs in the building near the entrance

facility for service providers and fiber running to the

RRUs and antennas on the roof. Buildings must have space

for entrance facilities, electrical services and cabling

for the systems. Some building may mount the antennas on

the building, some may have towers on the roof built for

the antennas. Cables run in the building will probably

have conduits or cable trays for managing all the

necessary cables. Most issues will be negotiated with the

building owners and managers.

Small Cells

Small cells go by many names including microcells. They

are small integrated radios and antennas intended for

small geographic areas. They can cover the range of 700MHz

to 2.6GHz with power outputs from 1-5W, much less than

regular cellular antennas. They are intended to be be

mounted on typical urban fixtures – walls, street lights,

traffic lights, bus stops, whatever gets them slightly up

off the ground. Because they cover smaller areas than

regular cellular antennas, they will have fewer users

connecting, spreading out available bandwidth to increase

bandwidth available per user.

Two small cells in an outdoor housing

Most will require only a single SM fiber and DC power

making installation easy where fiber optic cable plants

are available. Fiber technology for installations is

standard OSP and premises – nothing new required. We

understand they can even use PON technology to reduce the

electronics near the antenna. You can place several of

these small cells in one dome providing extended coverage

over many frequencies.

Cabling Options - Prefab

Assemblies or Terminate Onsite?

Most FTTA cables will be prefabricated in a

factory for the length needed for the tower, so field

termination is not necessary. If you need to terminate

onsite (hopefully at the ground level only), there are

options with prepolished/splice connectors that produce

good results – just check the manufacturer’s

specifications to see if they are rated for the extremes

of temperatures expected in the location of the tower.

Fusion splice-on connectors or pigtails may be more

reliable for extremes of temperature.

The FOA training curriculum and Guides have information on

termination in

general and every type of fiber optic termination.

See the Table

of Contents of the FOA Guide.

Connector Handling And

Cleaning

You must never assume that factory-installed

connectors are perfect or stay clean. Certainly they

should have been perfect when made and tested at the

factory, but the factory puts protective caps on the

connectors to ship them. We call those caps “dust caps”

and, as the joke goes, they are called “dust caps”

because they are usually full of dust. So after you

receive the cables, you should first remove the dust caps

and inspect the connector ferrule end face for dust and

scratches. Then you clean them, inspect to assure yourslef

the cleaning was done properly, then test them. Likewise

before you insert them into the receptacles to mate with

another connector, give them a quick dry cleaning before

insertion.

Never touch the end of the connector because the oils on

your finger will

Dirt is the #1 enemy of fiber optic connectors because it

can cause loss and reflectance, even damage connectors.

Inspect every connector before you make a connection with

it. Check the connector and the receptacle it will be

plugged into as either or both may be dirty.

Here is more information on cleaning

and inspecting

connectors.

Testing FTTA Cables

When dealing with prefab cables, testing involves careful

cleaning and inspection with a microscope, insertion loss

testing and in some cases, OTDR testing.

Like any fiber optic cable and especially any prefab

cable, the tower cable should not be installed until it

has been tested to confirm that the cable is OK. This also

includes the patchcords used on the tower. Even short

cables can cause major problems if they have been damaged

or are not clean.

Testing includes cleaning and inspecting the connectors,

checking continuity with a visual fault locator (VFL),

then do a loss test with an optical loss test set to

determine if all fibers are OK. Recording this data will

help in the final test, after the cable has been

installed, by comparing losses before and after

installation to see if any damage was done during

installation.

Remember to always keep protective caps on all the

connectors except when cleaning, inspecting or testing.

After installation, the cable needs to be tested again to

ensure no damage was done to the cable during

installation. Insertion loss testing and perhaps OTDR

testing will be required.

More

on FTTA testing.

More On Fiber For

Wireless

FTTA- Fiber To The

Antenna

Testing FTTA

Fiber

DAS - Distributed

Antenna Systems

Small Cells

WiFi

- Premises Wireless

Comparing

WiFi, Small Cells and DAS.

FOA

Guide Table of Contents.

|