Standards Update Rural "Super WiFi" Means More Fiber Test Drive - Prepolished/Splice Connectors UC Berkley Grows Lasers on Silicon Chips Top Ten Telecommunications Forecasts for the New Year New @ FOA Fiber U - two new free online self-study courses Publications: NECA/FOA 301 Installation Revised, eBooks Online Reference Guide: New pages on BI fiber, data centers, more Tech Topics: More online information Certification: New FOA OSP Certification FOA Schools: New schools and programs FOA Jobs Web Site Events: Conferences and Shows of Interest To Fiber Techs Q&A: Large number of good questions this month. Product News - Tiny splicer, more bend insensitive fibers Worth Reading: 2 New Lightwave Special Reports. More interesting things we've read (and videos we've seen.)

|

It's now CFOT® and Fiber U® The FOA CFOT® (Certified Fiber Optic Technician) and Fiber U® (the FOA online self-study program) are now a registered trademark. With over 31,000 fiber optic techs holding CFOTs and the CFOT being recognized worldwide as the foremost certification in fiber optics, the FOA realized the value of the CFOT and Fiber U required trademark protection. Now it's official! Want to know more about fiber optics? Free Self-Study Program on "Fiber U®." Looking for specific information? Study for FOA certifications? Here's the largest technical reference on the web: The FOA Online Fiber Optic Reference Guide. New FOA Reference Books(Available Printed or eBooks)

|

| Renew your FOA certification online - plus get a discount coupon for the new FOA books and get an extra month free. Details here. |

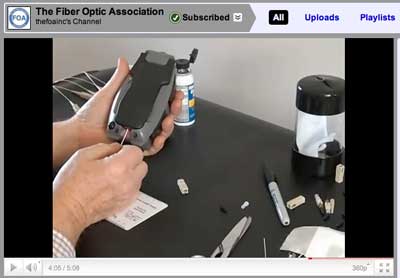

What Is Going On With Bend-Insensitive Fiber? The cover of the January 2011 CI&M was provocative - why was fiber the subject of a battle? Why were two articles on two sides of an issue facing each other in the magazine?  The topic was bend-insensitive fiber and its compatibility with regular fibers. We're run articles about this in this newsletter before because BI MM fiber requires special mandrels for mode filtering to standards for launch conditions. (See the note about Corning in Product News below for a followup.) The CI&M articles relate to insertion loss when mating BI and regular MM fibers. The way BI fibers work (see our new page on BI fibers) is to reflect light lost from the core of the fiber back into the core using a ring of lower index glass around the graded-index core. The light reflected back into the fiber stays in the higher order modes creating a larger effective core size and NA than regular MM fiber of the same geometrical core diameter (50 microns in this case, as BI fibers are either OM3 or OM4 types.) Since mating a fiber with a larger core of NA to one with a smaller core and NA creates excess loss at the connection, mating a BI fiber to a regular fiber could lead to excess loss. Maybe, maybe not. The worry about excess loss assumes that the core of both fibers are the same and that may not (should not!) be true. When designing a BI MM fiber, (some manufacturers claim) the core profile can be made differently to ensure the effective core diameter and NA are compatible with legacy fibers and, as a benefit, produce a fiber with better and more predictable performance. So the concerns expressed in the first article (by Panduit) may have been legitimate when considering the first (and maybe many current*) BI MM fibers, but the evolution of fiber designs probably makes (or will eventually make*) the issue no longer relevant. The second article (Corning's article) claims it is possible to make a BI fiber that is fully compliant with international standards - and it should be safe to assume that all manufacturers will do the same as soon as possible. These two articles in CI&M illustrate one problem in dealing with technology - often information we receive is from a "snapshot" taken in one moment in time - while technology continues to evolve in the background. It reinforces the admonition to not jump to conclusions based on small samples of data from limited numbers of sources. It also shows why the FOA participates in standards activities, as this compatibility was a major topic of concern at standards meetings where we were able to understand the issues and learn how solutions were developed. *And the comments in italics indicate there is not general agreement among those in the industry. After this article was first published, we received comments that indicate that not everyone in the industry feels a solution is that close, leading to the new text. How long will it take for there to be compatibility between new BI fibers and legacy fibers - or how long will it take for different manufacturers' fibers to be compatible? What are the implications of BI fiber designs beyond mating loss - like bandwidth which was raised as an issue at the TIA meeting discussed below? Stay tuned for more on this topic -including the article on standards below. And in the meantime, ask these questions of your fiber/cable manufacturers. The FOA has created a new Reference Guide page on bend-insensitive fiber. Standards Update It is important to remember that standards take a long time to work their way through committees. It's also important to remember that they are developed by manufacturers who often develop products long before the standards are completed. But sometimes standards get written before the products to support them get fully deleloped and sorted for production. Knowing that helps understand what is going on in the fiber optic committees right now, especially on two topics, BI fibers (see above) and EF (encircled flux). Encircled Flux Encircled flux has been written into the international standard for testing MM fiber (ISO/IEC 61280-4-1) which has been adopted by TIA to replace the original version of OFSTP-14 so US and International standards are the same. These two standards replace the older CPR/mandrel wrap with EF requirements for mode power distribution in launch reference cables for MM testing. EF was not developed for testing, however. EF began as a theoretical simulation of a conservative VCSEL to use in calculating bandwidth of ideal fibers during the development of the 10 gigabit Ethernet standard. A company in the UK that sold a modal fill tester built a few mode conditioners that approximated EF according to their equipment and used them to test links with 2 dB loss to show it not only made different sources provide consistent loss measurements but even made OTDRs agree with OLTS (light soure and power meter) tests. (The FOA acquired several of these mode conditioners and could not reproduce their results. In fact, we found that it did not even make two OTDRs agree at higher loss values!) EF was adopted into test standards as a "better" way to define an ideal source for testing fiber. In fact, the EF standard is very close to the current CPR/mandrel wrap method but should be more reproducible. The use of EF, however, depends on 1) being able to test sources for conformance and 2) producing a practical EF launch for testing. That may be some time off. Right now, there is a second international "round robin" starting to see if about a dozen companies can get reproducible EF measurements, and this round robin may take longer than a year. The first round robin was inconclusive. And we've talked to several test equipment vendors who are not yet ready to support EF unless you buy one of the expensive mode conditioners from the company who started it all and trust their results. So right now, EF is part of the TIA OFSTP-14 and ISO/IEC 61280-4-1 standard but is not a proven technique. It is at least a year away from being a trustworthy standard. In the meantime continue doing what you are doing now! We've added more on EF to our Reference Guide web page on MM modal distribution. Bend Insensitive Fiber BI fiber has been on the market for some time, but as a technology, it's still evolving. However, it is probably going to be the only type of OM3 and OM4 fiber available in the future. The issues of compatibility, aired in the CI&M articles above, have required some comprehensive analyses by fiber manufacturers and some fiber design engineering to ensure compatibility. Presentations at a recent TIA meeting indicate that making BI fiber that is both compatible to current designs and meets international standards for these fibers (yes, there are detailed international standards for components like fiber) is possible (although that conclusion is controversial at this time and subject to considerable debate in the standards committees). Some of the first BI fiber may have some excess connection losses when connected to legacy fibers, but newer fibers are being designed to be compatible, within design tolerances. Remember the variations of specifications like core diameter and NA for production fibers can be quite high - even if real fibers are much more consistent - but fibers on the high end of production tolerances are probably going to give loss results that are also beyond what should be expected from nominal fibers. Bottom line, don't worry. Well, maybe worry for the next year or so while the bugs get ironed out. Read the article above about the controversy aired in CI&M magazine and the follow-up comments. The FOA has created a new Reference Guide page on bend-insensitive fiber. UTP Copper Manufacturers - They're Like the Energizer Bunny.... "This is a call for interest for individuals to contribute to the formulation of a new structured copper cabling standard: Balanced Twisted-Pair Telecommunications Cabling and Components Standard, Addendum 1: Specifications for 100Ω Next Generation Cabling. Scope: Develop a new category of cabling to support future applications beyond 10GBASE-T. This is a new project under the direction of TR-42.7 Copper cabling systems subcommittee." Need we say more? Rural "Super WiFi" Means More Fiber Reaching the rural areas of the US or any large country with sparse population can be very expensive. The US has a plan, however, that may make it more affordable. "Super WiFi" is not your usual WiFi. It is using WiFi protocols but broadcasting on frequencies of unused TV channels. The FCC is ready to open up new frequencies to broadband to allow delivering broadband Internet and phone to rural areas where cabling is too expensive. Of course, fiber will be needed to the wireless towers to deliver broadband signals.  An example of a super Wi-Fi antenna: Altai An example of a super Wi-Fi antenna: AltaiSuper WiFi works at a lower frequency than either regular WiFi or cellular systems so it has more reach into areas that are too rugged for most wireless systems. Usage in more urban areas may be a problem however, if there are too many broadcast TV stations which can interfere with Super WiFi signals (and vice versa.) More in MIT Technology Review And the US Government Announcement. And on the cellular wireless front - they need more fiber too: Cisco: Mobile data continues to surge, driven by smartphones and tablets In its latest update to its annual Visual Networking Index, Cisco found that its projections for 2010 were a bit too conservative. Actually data traffic globally grew 160%, 10% faster than Cisco expected. Read More. Test Drive - Prepolished/Splice Connectors The first no-adhesive, no-polish connectors were introduced several decades ago and most versions have disappeared, a result of poor performance and high cost. Only the prepolished/splice (PPS) connectors, which have consumed immense amounts of R&D, have survived. Now we have two types of PPS connectors, the traditional ones with a polished fiber stub and a mechanical connector in the backshell and the new ones with a fiber protruding enougth so it can be fusion spliced onto a fiber. The fusion splice ones have been successful from introduction, as fusion splicing is the most reliable way to get a low loss fiber joint. PPS connectors with mechanical splices are harder to get right, requiring good fiber cleaves and some indication of splice quality during termination. The secret to the PPS connectors with mechanical splices was 1) use a fusion splice quality cleaver to get good cleaves, not the cheap "stapler" type cleaver and 2) use a visual fault locator (VFL) to test and optimize the splice as it is being made. Corning has developed a new PPS connector kit, the Unicam® Pretium™ kit (more info) that addresses both these concerns. It has a quality cleaver that is easy to use (it even has fiber scrap storage) and a installation tool that includes a VFL to check the splice as the connector is being made and tell you if it needs tweaking by working the fiber being terminated. We recently used one of these kits to create a new YouTube video on PPS connectors. You can watch the YouTube video to see how easy the kit is to use, how quick the termination process really is and how it confirms you have a good termination. While making the video, we made a bunch of patchcords and only once had to tweak the fiber before getting an OK from the installation tool. Then we tested the patchcords. Remember each end of the patchcords had a PPS connector - with a connection loss plus a splice loss - so we had a connection loss and two splice losses in each cable when tested single ended - but the average loss was only 0.7 dB for each patchcord. If we assume a connection loss of about 0.1 dB, not unusual for a good polished connector ferrule connection, that means each splice was about 0.3 dB and a typical connector loss (splice plus connection loss) would be ~0.4 dB - well under the 0.75 dB allowed by cabling standards and not much above what an average installer can expect with adhesive/polish connectors. If we can sit down with this kit and with little practice consistently make 0.4 dB connectors, we're convinced that these PPS connectors are a viable alternative to traditional adhesive/polish connectors. You do need to be careful with the cost issues because adhesive connectors are still much cheaper, but the time savings of PPS connectors may make them cost effective, especially when only one or two connectors need to be done at a location.  View the FOA YouTube video on Prepolished/Splice Connector Termination. UC Berkley Grows Lasers on Silicon Chips As integrated circuits like microprocessors get faster, copper connections are not keeping up with the speed of communications between chips. To make copper work faster takes power and power is hard to provide on the scale of current ICs. Optical connections are better because they are faster and use much less power (the reason that fiber is preferred for networks at 10 Gb/s and above). But ICs are made of silicon which is not compatible with making optical emitters which are made of more exotic semiconductor compounds. Now some researchers at Berkley have figured how to grow lasers made of common laser materials on top of silicon ICs without damaging the ICs. The lasers are grown as tall peaks on the silicon substrate and should be easy to couple to optical fiber. Read more. Top Ten Telecommunications Forecasts for the New Year Information Gatekeepers today announced the availability of IGI’s forecasts for 2011. Every year, Clif Holliday, author of the Lightwave Series of reports, prepares his view of the most significant events likely to underpin telecommunications for the coming year. While Clif likes to take a somewhat lighthearted approach to this forecast (as you can see from its title), his accuracy has been exceptional. He is one of the few New Year’s prognosticators who always prefaces his new forecast with a review of the accuracy of last year’s forecast. This gives the reader a sense of how much creditability to put in the forecasts for the coming year. Top Ten Telecommunications Forecasts for the New Year Wireline loss will continue, but only at 1.5%-2% per quarter for the major RBOCs. Growth of advanced high-speed access will recover and begin to show more strength as the major telcos take advantage of their buildouts (FiOS and U-verse) and focus on marketing and improvements. We expect high-speed penetration to reach 70% households (about a 4% increase. We forecast that the high-speed access between telcos and cable companies will be about 45% (favoring cable) by year-end — very little change. Enterprise revenue of the major telcos will begin to recover from the recession and should be at least slightly positive year-over-year. Capital spending will be higher than 2010. We expect to see a 5%-10% increase in capital spending year-over-year. This will be based on increased spending in the network infrastructure areas, and in improving the already deployed access networks. In addition, some of the stimulus spending will show up in these figures. Overbuild has not become a basic strategy of major telcos, as we suggested last year. We still think this will become more than a test vehicle for Verizon. This year we forecast that either Verizon or AT&T will make a major move in this area to expand overbuilding. Our report “Overbuild — the New RBOC Advanced Architecture Strategy” details this. Security of networks will become an even bigger issue. Smartphones that can use Wi-Fi access as well as network access will become a major security problem for corporations. Goggle will make a major telecommunications announcement this year. Its FTTH project will proceed, but it will lose impact compared to the massive projects of the major telcos (and even many smaller ones). However, Goggle will be in the middle of some major telecommunications story in 2011. We forecast Internet network traffic to continue growing at about 25% to 30%. This is based on the work now completed for our upcoming report “Network Traffic Forecast — 2011.” This is considerably lower than normally forcest, but we think fully justified. The Internet is getting so large that high growth rates are not sustainable. Mergers — We think another major telco equipment manufacture or service provider will either go into bankruptcy, be merged into another one, or leave the US market. With share prices still relatively low, this may be a real opportunity for a lot of M&A activity. Google may be a major player in this area. Events of Interest  Fiber U Returns @ OSP Expo, September 13-14, 2001 Some of you may remember the famous "Fiber U" training conferences of the 1990s where dozens of vendors and hundreds of students converged for a week-long training conference. Now Fiber U is part of the FOA. This year we've been invited to work with OSP Magazine to present seminars at their annual conference. We'll have sessions on Fiber Optics in SmartGrid, Wireless and Gigabit FTTH! OSP Expo, September 13-14, 2001 will be held in Cincinnati, Ohio.  Web Conference: LAN Standards, News & Trends: 2011 Update Date: Thursday, March 3, 2011 Time: 11:00 a.m. - 12:15 p.m. EDT Members of the Fiber Optics LAN Section are pleased to present Herb Congdon of Tyco Electronics and Standards Chair of FOLS presenting LAN Standards, News & Trends: 2011 Update. Register here.  OFC/NFOEC is the world's leading global conference and exposition for optical communications and networking professionals. Technical Conference March 6-10, 2011 • Exposition March 8-10, 2011, Los Angeles Convention Center, Los Angeles, CA, USA. More. Free Corning "See the Light" Seminars Corning is offering free 3 hour seminars on "Termination Technology" in over a dozen cities around the US in the coming months. The seminars focus on new termination techniques and will give attendees real hands-on training. You must pre-register for the seminars, and we recommend you do so soon as they will probably fill up quickly! March 9 Raleigh, NCRegister at http://registration.corning.com/1STL%2D2011/ Broadband Properties Webinar Archives  Lots of interesting webinars, mostly on FTTH. Go here.  What's New @ FOA What's New @ FOA Two New Free Fiber U Self-Study Programs on Outside Plant Fiber Optics and OTDRs There are two new free online self-study programs on Fiber U. "Outside Plant Fiber Optics" uses the new FOA textbook and online reference guide to OSP to help you learn about OSP fiber networks. The "Understanding OTDRs" self-study program will help you learn how to properly use these complicated instruments and there is a free OTDR simulator you can download to use for practice. FOA Certification On Outside Plant Fiber Optics The new FOA CFospT outside plant certification focuses on OSP fiber optic network design, installation and maintentance. A CFospT certified tech must know the ways that fiber is used in the OSP, how it is installed, tested and maintained. While a CFOT might only have a basic knowlede of fusion splicing and OTDR testing, for example, a CFospT will be knowledgeable and skillful in those areas - and more. Reference materials for the new CFospT are the printed textbook, the FOA Reference Guide to Outside Plant Fiber Optics (right) as well as eBooks from Amazon for the Kindle or Apple for the iPad/iPod/iPhone and the OSP reference section of the FOA Online Reference Guide which now includes a self-study guide to the CFospT exam. More information on the FOA Outside Plant Fiber Optic Technician (CFospT) certification. Want to know more about OSP? There's OSP Magazine for that - and a trade show, OSPExpo, running this fall in San Antonio.

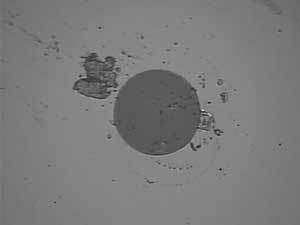

We have created three new FOA books to be used in training for FOA certifications and as reference books for contractors, installers and end users of fiber optics. These books have full curriculum support, including free curriculum materials for teaching FOA certification courses. Because we are self-publishing these books using more modern "publish on demand" technology, they are easier to keep up to date, easier to buy and much, MUCH cheaper! All are now available in print and electronically in Kindle and Apple iBook versions. Details on the new book each of the new books are at the book pages linked to the photos above.  Standards cover components and systems and how to test them, but rarely get into installation issues. The FOA NECA 301 standard which covers installation of optical fiber systems has been revised for the second time, adding considerable new materials. This standard is derived from FOA educational material put in standards form and approved by ANSI as an American National Standard. It's specifically written to be used in contracts to define "installation in a neat and workmanlike manner." The standard is available from NECA. The FOA is dedicated to make technical material readily available to all those interested in fiber optics. For all 15 years of our existence, we've created reference materials in the form of printed textbooks and web pages. Now our Online Reference Guide has grown so large it needs it's own Google Search and we offer all three of our new books on the Amazon Kindle or Apple iPad/iPhone/iPod. Recently we started our own channel on YouTube and the response has been enthusiastic. So we've been adding more videos to YouTube, including a demonstration of how to use your cell phone camera to detect IR light in fiber systems and have started a lecture series on fiber optics. The first lecture is called "Fiber Optics and Communications" and FOA President Jim Hayes describes the many different uses of fiber in telecommunications, CATV, security, utility and many other networks. Lecture #2 is all about safety in handling and installing fiber. Future lectures will cover the basics of fiber and cable, termination and splicing, installation and testing. FOA Online Fiber Optic Reference Guide New Web Page on Bend Insensitive Fiber Bend-insensitive fiber is a "hot topic" now - we try to explain how it works and what it means for installation and test. Basic Fiber Design Section Updated Lots of new materials added to this introduction to fiber optic design. New Web Page on Data Centers Data centers are the heart of the Internet, storing and supplying data for user requests. Needless to say, high performance cabling is needed to move the data between storage, servers and routers. We've created a new pagein our Online Reference Guide on data centers - how fiber and cabling are vital to their performance. Learn More About OTDRs - Download a Free OTDR Simulator More and more installers are being asked for OTDR testing but using these instruments is not easy. They are hard to set up properly and complicated to interpret the traces. Using the autotest function can lead to disastrous results! The FOA has a good tutorial on OTDRs on our Online Reference Guide and we added a free download of an OTDR simulator to the OTDR section so you can learn how to use an OTDR on your PC. New OSP Reference Section on the FOA Online Reference Guide website Joining our basic fiber optics and premises cabling sections on the FOA Reference Guide website is a new outside plant reference section that covers materials like that in our new textbook. The material is ready for use and will be followed shortly by a self-study guide. Both the OSP textbook and website are references for the new FOA CFospT outside plant technician certification. More New Info: Links to manufacturers and distributors of fiber optic lighting products. The FOA Online Fiber Optic Reference Guide has become very popular - perhaps the most popular technical website ever, typically with over 270,000 users downloading about 1.6 million pages in 2010! We continue updating materials regularly, keeping it as up to date as possible. Find What You Want Using "Google Custom Search  There's

so much information on the FOA Tech

Topics and Online Fiber Optic Reference Guide

that even a well-organized Table of Contents isn't enough and when the

material is always changing, an index is impossible to maintain. So the

FOA is using the latest technology in search, Google Custom Search,

which will allow you to search just the

FOA Tech

Topics and Online Fiber Optic Reference Guide for

any topic you want to find more about. Try

it! There's

so much information on the FOA Tech

Topics and Online Fiber Optic Reference Guide

that even a well-organized Table of Contents isn't enough and when the

material is always changing, an index is impossible to maintain. So the

FOA is using the latest technology in search, Google Custom Search,

which will allow you to search just the

FOA Tech

Topics and Online Fiber Optic Reference Guide for

any topic you want to find more about. Try

it! Go to The FOA Online Fiber Optic Reference Guide. School News New Outside Plant Technician Class Gateway Community and Technical College (Cincinnati, OH, USA) has completed its first Outside Plant Technician course.   Tom Collins, Instructor, is at Left Tom Collins, Instructor, is at LeftThe outside plant technician course consists of installation and operation of communication systems located outside building structures. The course of study includes the smart grid, fiber optic systems, Power Line Carriers (PLC), and cellular technology ,wireless systems, and copper cable systems. Recently a guest speaker from Duke Energy presented the Smart Grid systems and how it communicates within the grid systems. After the presentation the students built a grid system made of 10 kilometers of fiber optic cable with connectors and splices to mirror workplace conditions. The students then had to use meters to troubleshoot faults set up by instructor. In addition, the class took a new Fiber Optic Association certification test, Certified Fiber Outside Plant Technician (CFospT). This certification is recognized internationally and ALL of the Gateway Students successfully passed the certification test. The Gateway students were the first class not to use a textbook but used the Fiber Optic Association (FOA) online reference materials and the FOA kindle and ibook applications. “We are created history this semester at Gateway Community and Technical College” stated Professor Thomas Collins, “first, we are changing the way we deliver technical courses/labs to be accessible using different media, second, offering a hands-on course that covers communication systems used by the energy industry”. This program evolved through a Department of Labor grant to fund a lineman-training program. Our energy committee decided to expand the lineman program and to add the Outside Plant (OSP) certification. The smart grid installed in our area afforded us the opportunity to develop a new worker classification called the Outside Plant Technician. We must recognize our industry partners for their support of this program; the Gateway Community and Technical College Energy Committee, The Fiber Optic Association, Duke Energy, Bowlin Group, and Corning Cable. New Schools The FOA welcomes the newest additions to our listing of FOA-Approved Training Organizations: Big Time Telephone Service, Marina Del Rey, CA, USA, #314 Want to Own The Best School in Canada? Mississauga Training Consultants is looking for a new owner. This 15 year old company is a great opportunity for someone who has fiber experience and likes to teach. Also a great way for a current school to establish a presence in Canada. William will work with the new owner for up to six months to help them get established and grow. If there is not a new owner by April I will consider breaking the company up and selling it in pieces. The web site www.fiberoptictraining.com has top rating. William Graham, CFOS/S/T/C/D/, CFOI Mississauga Training Consultants email: mr.bill.graham@sympatico.ca www.fiberoptictraining.com Tel: 905-785-8012 Cell: 416-659-8713 Find a listing of all the FOA-Approved schools here. It's Now A Lot Easier To Find A FOA-Approved Training Organization  Most phone calls we get regarding finding a FOA-Approved training organization want to know two things: what school is closest to me or what school offers the certifications I need. That can be difficult, since the FOA has almost 200 training organizations we have approved worldwide! We've been looking at ways to make it easier, and we think we've got a good solution. In fact we have two solutions. First we have added a sortable table of all the FOA-Approved schools. You can also use our FOA Google Map Application to find FOA-Approved schools. Here are links to the sortable table of all the FOA-Approved schools and FOA Google Map. What Should A Fiber Optics or Cabling Tech Know and What Skills Do They Need? The FOA has been updating its lists of KSAs (Knowledge, Skills, Abilities) for fiber and cabling techs. The updated list is now on the website for your information and comments - as fiber and cabling KSAs evolve as new technologies develop. KSAs for fiber and cabling techs. Good Question! Tech Questions Worth Repeating Tech Hint: Did You Know You Have A Fiber Optic Tester In Your Pocket? Yes! The camera in your cell phone is sensitive to infrared light - lots more than your eye - and can detect light in an optical fiber or from a transmitter. Chris Hillyer,CFOT/CFOS/I, Master Instructor, Northern California Sound & Communication JATC sent us some photos showing how this works. See below or the video now on YouTube. Termination Times Q: Has your group ever done a study or analysis on how long it takes to complete assorted field terminations? I’m looking for average values as there can be so much variation due to skill level, equipment availability, experience, etc. A: Around 1997, several of the Fiber U instructors did a comprehensive time and motion study on termination. They compared several types of termination processes under several different scenarios, since sometimes you only do one or two connectors at a location and sometimes a dozen or more Times were based not just on termination times, which are in the data tables, but also setup, cable prep and cleanup times to make the analysis representative of real world installations. And while the instructors involved then were very skeptical of prepolished splice connectors then, they have become much better! (see above) However, I think the times are still representative. And the cost data can be updated to represent current prices for the connectors. Read the article on termination times. Mix and Match Connectors Q: With SM fiber, can one end have SC/APC to the equiment and SC at the patch panel? Patch panel is in place and equipment needs APC. A: Use a SM patchcord with one end SC/APC and one end SC. Just specify a higher grade of PC polish (UPC is what some vendors call it) to reduce reflectance. That's Why They Call Them "Dust Caps" Q: We clean a connector, inspect it to ensure it is clean then put the dust cap on. If we inspect it after we remove that dust cap, it's dusty again, we assume from dust in the cap. I have tested different types and makes of dustcaps for the LC and clean ones are rare. If you only push them on half way it helps.....sometimes, but not always. Does any company make clean (guaranteed) ones? A: I've been saying for years that the reason they call them "dust caps" is they contain lots of dust. I know of no clean ones. Think about how they are made in millions and dumped in big bins in a factory! You just have to clean connectors when you remove them. Have you tried some of the dry cleaners? They seem to work well. Midspan Entry Q: How difficult or easy is it to fusion splice one buffer tube and leave rest of the buffer tubes uncut in a fiber optic cable? This is in regards to carefully cutting only one tube, while not damaging the fibers in the other tubes of the fiber optic cable. A: You can get a special tool for this process which is called "midspan entry." Check with the cable manufacturer. Here is a link to a special Draka tool. Single Mode 850 nm VCSEL ? Q: One of our members wanted to know what this headline meant: "VI Systems launches ultra-fast 850-nm singlemode VCSEL for datacom" (Lightwave) Is this a laser intended for singlemode fiber? A: A good example of confusing nomenclature. SM in fiber means the light travels in only one ray so no modal dispersion. SM fiber is small core, about 9 microns for 1310 nm and 5 microns for 850 nm (and yes some 850 nm SM exists, mainly for sensors.) In lasers, singlemode means only one wavelength of light - no side lobes at a few nm away with some power, which can cause chromatic dispersion in any fiber. Fiber IN The Home Q: I have fiber and cat5e runs to every room in my house from an OnQ box in the garage. The former homeowner spent alot of money on cable preparing for the next generation of high speed voice data internet. My goal is to create a Fiber Optic LAN for audio/video distribution for the whole house as well as integrating smart home tech such as control of Hvac lighting and security. I have had afew a/v guys come out and look, it's pretty obvious they have no idea what they are looking at and quote insane prices. With some elbow grease and some advice I know I can accomplish my goal using off the shelf software and hardware (Linx software, and a small profile Solid state pc for network and home control) can you help me? A: What you need are media converters. You can get them for Ethernet, various other data networks, video, audio, etc. The software doesn't change. The FOA has a tutorial on broadband in homes: http://www.thefoa.org/biasc/ Here are some sources: http://www.versitron.com/index.html Cable Plant Documentation Programs Q: We provide design and engineering for the telecommunications industry, including fiber optic design. We are looking for a computer application or customized database for fiber optic documentation. Can you point me in the right direction? A: We know of no pure FO documentation programs today - although we created one when we were in the manufacturing business about 20 years ago that died for lack of interest. Bellcore/Telcordia used to offer one but I do not know if it's still available. It was horribly expensive - designed for the telcos. We know people who use spreadsheets and CAD programs they developed themselves. Companies offering bidding programs for electrical contractors (Accubid, McCormick Systems, etc.) have added fiber and structured cabling to their programs and may have something you can use. More on Loss Budgets Q: Reading your tech article labeled lossbudg.htm, I think there are some redundant losses calculated. You show a setup with a TX connected through other connectors (patch panel) a splice another patch panel and connected to a receiver. You state that you consider all of the connectors to have loss, including the connectors at each end. I question this concept. When a fiber optic transmitter states the output power parameter, say -20dBm launched into 62.5/125 fiber optic cable, it already takes the connection to the transmitter into consideration. The fiber, once connected to the transmitter should be receiving -20dBm of light power. The same situation exist at the receive end. The receiver states that it has a maximum sensitivity of -32dBm, from a 62.5/125 fiber optic cable. The only way to measure this is to connect a fiber optic cable to the receiver and vary the power to determine the lowest level at which the receiver will operate then measure the light out of the fiber cable. This connector is part of the measurement and should not be used as part of the power budget calculation. I submit that the only elements to be considered in calculating power loss are the patch panel(s), splices, and fiber cable attenuation. If a TX states minimum power launch is -20dBm and the receiver states maximum sensitivity is -32dBm then this pair of equipment has an optical budget of 12dB. One should expect that when they connect the patch cable to the TX it will launch -20dBm and when they connect the patch cable to the RX it will launch all of the light exiting the fiber optic cable onto the RX. The only elements that can cause attenuation are those elements between the TX and RX connectors. A: The concept of the loss budget has two viewpoints: 1) The systems people need to know how much cable plant loss their transmitters and receivers can tolerate and 2)The fiber designers/installers need to know if their cable plant will support the communications system that is supposed to use the cable plant they install. Both need to know that the connections at the equipment couple the proper amount of light into the fiber from the transmitter source and transmit the proper amount to the receiver detector as well as the intermediate losses are within reason. The coupling at either end will only happen if the connectors on the ends of the cable are low loss. The cable plant designers and installers generally do not have the equipment onsite to use to test connectors for proper coupling to transceivers, but they do have the test equipment to test the connectors against another known good reference connector. Systems people who test their equipment for coupled power, however, do have the ability to test their products with known good connectors, so their coupled power numbers assume a certain performance level, e.g. low insertion loss, from the connectors used for the coupling. This line of logic has led us to have a convention of including the connections on the end of the cable plant in the loss budget. In the early days of fiber optic standards, there were some strays! IBM once used a 3-cable reference for their systems because they came to the same conclusion that you did and the 3-cable reference reduced the measured loss by two connector losses, making them think they had made the proper compensation. But the logic proved wrong (see http://www.thefoa.org/tech/ref/testing/5ways/lossmath.html) and they realized the 3-cable reference had a higher measurement uncertainty (see http://www.thefoa.org/tech/ref/testing/5ways/fiveways.html toward the end). Now by convention, when the systems people specify a power budget, they generally use the testing standards which include the connectors at the end, and I believe this is true for all standardized networks. So the method we specify works for both systems and cable plant analysis and is the accepted version. Have you ever tried to test coupled power with known bad or dirty connectors? It's an interesting experiment! And some transceiver's couplings are very different with 62.5/125 and 50/125 fiber. There are also test standards for coupled power and they specify using cables with tested connectors of low loss. Loss Values in TIA Standards Q: I have read the information about fiber optic test on the thefoa.org website. I also noticed that the TIA 568-C.3 Standard already came out. So does the 568-C.3 standard has different attenuation, connector loss and fusion splice loss than the 568-B.3? I am trying to establish the fiber installation standard for our plant, but I still new to fiber optics. A: The issue of what attenuation or loss values for components is under review at this time, but the current numbers are the same as before. The most contentious issue is connector loss, since 0.75 dB was chosen a long time ago to allow the inclusion of prepolished/splice connectors, which at the time were pretty awful! Today PPS connectors are better, around 0.5 dB max, and there is a recognition that the value needs updating since some 10G and faster networks will not work with more than 2 connections on the end using the 0.75 dB connector loss. But there are members of the TIA committee who do not want to change the values for various reasons. Internationally, they use a statistical method which is somewhat confusing! Splicing Q: I am splicing SC/UPC pigtails, about 6 meter, with single-mode fiber. My splices have always seemed good; I hit them with an OTDR and I barely see them, if at all most of the time. However, I was just using the VFL to check for macro bends, etc. and I am seeing a little bit of red light at my splice. The funny thing is, right after my splice, I see nothing….then after a minute or so I see the light emitting from the splice. Can you shed some ‘light’ on this for me? Is it normal to potentially see a little light escaping at the splice? A: What kind of splice protector are you using? If its a heat shrink type, it may be causing stress as it cools. We've seen that in connectors also. 10 Gigabit Link Deployment Q: I have laid and terminated a standard singlemode fiber cable of less than 1kilometer to service 10gig link. I have deployed X2-10GB-LR module on the switch ports but it has not responded. Do you have troubleshooting ideas? A: First, we assume you have tested the insertion loss of the link and it is within specifications. At 1300 nm, it should be ~0.4 dB for the fiber, plus connector and splice losses, and if continuous with no splices or intermediate interconnects, it should be ~ 1 dB. If that is the case, there are two potential issues: 1. Too much power at the receiver. Most of these links can operate over 6-11 dB (http://www.thefoa.org/tech/Linkspec.htm) so a 1 dB link may lead to overload at the receiver. This requires a inline attenuator at the receiver. Measure the power at the receiver and if too high, use a fixed attenuator to bring it to the right level for the receiver. You can also make a temporary attenuator with a SM patchcord would tightly around a pencil! See http://www.thefoa.org/tech/ref/appln/attenuators.html 2. Multipath interference. The reflectance of connectors at the end of short lengths like this can bounce back and forth in the link, causing noise. Remember the reflected signals would only be attenuated by 2 dB in a round trip on the fiber. If the connectors are UPC (ultra PC) or APC and in good condition, this will be less of a problem. Fiber Backhaul Instead of Microwave for Wireless Q: I am in a small remote alpine town creating a case to have fiber optic backhaul instead of the beleaguered microwave link currently provided by the iLEC. Could you please point me in the direction of any materials that would empirically support the advantages of fiber backhaul for remote sites vs the dis-advantages of microwave links. The microwave system we're trying to get the iLEC to replace spans about 35miles per hop, and "supports" three DS3 equivalent circuits; but real world performance is pretty poor from the end user's perspective. Since the town is fed with DSLAMs, it's tough to really load the link until all the tourists are here making cell calls, using mobile data, and occupying the residences & hotels -then the link really maxes out. If we have a busy weekend, and get 48" of snow over night - same thing - delay, jitter, congestions of the available path. A: Microwave has been used in many areas where fiber is hard to install, like mountains, but with the advent of 4G systems carrying lots of data and video, microwave is giving way to fiber backhaul. In fact, one of the biggest areas for fiber expansion today - plus they are using it to connect the antennas on the tower. Try this: http://connectedplanetonline.com/images/CP_ADC2_WhitePaper.pdf Buried Cable Depths Q: What is the proper depth to bury underground cables? A: We've researched this for our latest book on OSP fiber (http://www.thefoa.org/FOArgOSP.html) and can share with you our findings. The most widely used "rule of thumb" is bury fiber 3-4 feet (1-1.2m) deep, with a ton of exceptions. In suburban areas where cables are grouped and marked and backhoes are less likely to dig up cables, it's not uncommon to bury cables 18-24 inches (~0.5m) deep. In areas with "cable congestion," like Boston during the "big dig" cables were at all depths - many much deeper. In cold climates, freezing water in conduit can be an issue and cable manufacturers are capable of supplying special cables for these installations. About 15 years ago, we worked with a project to test fiber at the Scott-Amundsen base in Antarctica where fiber optic cables were run aerially, direct buried and run in conduit with no problems. Although I've been in MN in mid-winter and thought it was like Antarctica, I thing the real place is probably worse! Our answer, then, is shallower depths are OK as long as the cable is chosen appropriately for the installation. Fiber Cleaning This is a topic we keep reminding everybody about, and here is why: From a contrator in the Middle East: Here some samples of the connectors for SM fiber already installed in the system we were testing.   As you can see, the dirt is large compared to the size of the fiber (dark gray), and the core (not visible here) is only 9/125 of the overall diameter of the fiber! See Product News below for links to vendors of fiber cleaning products. Measurement Uncertainty: Everyone testing fiber optics should understand that every measurement has some uncertainty - whether you are measuring loss, length, wavelength, power, etc. Knowing that uncertainty is very important to interpreting the measurement. It's worthwhile to read and understand the issue of measurement accuracy covered in this page of the FOA Online Fiber Optic Reference Guide. Worth Reading: Free editorial guide highlights optical enterprise networks: The Benefits of Fiber for Enterprises With data rates approaching 10 Gbps in many applications – and beyond in some data centers and high-performance computing applications – fiber is becoming less of an option and more of a requirement for many enterprise network managers. This Lightwave Editorial Guide outlines the many new technologies and strategies that have made optical networks less expensive to deploy and manage for enterprise applications. Sponsored by Avago Technologies US Inc. Read More Optimizing Smart Grid Communications with Fiber Smart grid means more than just automatic meter reading. Adding intelligence, improved monitoring, and flexibility to utility grids puts an increased emphasis on communications capabilities. This Lightwave Editorial Guide reviews how fiber, because of its ability to support high data rates and low latency, is a natural for emerging smart grid requirements. Sponsored by Avago Technologies US Inc. Read more Verizon invested more than $1.4 billion in New York landline telecommunications infrastructure in 2010 Verizon spent in excess of $1.4 billion in enhancements and improvements to its New York landline-based network last year. (Lightwave) Searchable IGI Publication Archives Now Available as Google eBooks Information Gatekeepers Inc. (IGI), a leading international supplier of information on fiber optics and telecommunications markets and technology, has entered into an arrangement with Google to make its archives available as Google eBook. Since 1977, IGI has been publishing newsletters, conference proceedings, market research reports, and other publications focused on worldwide markets in telecommunications and fiber optics. With Google eBooks , all of these publications and studies — including previously unavailable earlier works — are now available in searchable, electronic format to market researchers, financial analysts, lawyers, governments, university researchers, libraries, and all other interested parties. Please search our new archive by visiting igigroup.com or entering search terms in the box below. The new Google eBooks of IGI publications are also the best available for reading on mobile devices. Google eBooks can be read on the Web, Android phones, iPhone, iPad, iPod touch, and supported eReaders. Learn more about our supported devices. For more information on the new Google eBooks of IGI publications please visit igigroup.com. You can search Google Books for IGI publications directly - Go here. Ensuring Distance Accuracy On OTDR Measurements By JDSU.  If you think the Internet has changed communications in recent years, consider the effects of the introduction of telegraphy 150 years ago. Communications went from as slow as horses, ships or trains could carry news to instantaneous! Who was the first to use it? Stock traders, of course, and low latency is still their goal! It's a good read, and you'll find out some new info on Thomas Edison! On Amazon. Broadband Properties Webinar Archives  Lots of interesting webinars, mostly on FTTH. Go here. FTTX Networks An ADC white paper on how they work and how networks are upgraded to FTTH. http://connectedplanetonline.com/images/CP-ADC3-WhitePaper-v4.pdf. JDSU Application Note On "Qualifying FTTH Network before Equipment Installation" Another great paper from JDSU covering FTTH PON networks is available for downloading. It gives an overview of FTTH architecture, cleaning connectors then testing the cable plant with OTDRs and OLTSs. This paper will help you understand why OTDRs can be confusing on PONs! Best Practices For Wireless Backhaul Network Upgrades Joan Engebretson, Contributing Editor of Connected Planet has written a very good overview of how fiber is essential to the operation of cellular wireless systems. Everybody probably knows that fiber is used to connect towers into the telecom network - they call it backhaul - but her article also covers the new appliations to replace bulky, heavy, lossy coax up the tower to the antennas. http://connectedplanetonline.com/images/CP_ADC2_WhitePaper.pdf. Fiber Optic Safety Poster We've had numerous requests to reprint our guidelines on safety when working with fiber optics, so we have created a "Safety Poster" for you to print and post in your classroom, worksite, etc. We suggest giving a copy to every student and installer. Corning now offers videos on  .

Lots of interesting videos, some technical, some sales, but all good

information. .

Lots of interesting videos, some technical, some sales, but all good

information.US Conec's videos on cleaning fibers - show's the results of proper cleaning. Webinars of Interest Broadcast Engineering Magazine - Fiber Optic Testing FOA President Jim Hayes presents an overview of fiber optic testing for all applications. Available on Demand. Sign up here. Multimode Fiber Trends from TIA's Fiber Optics LAN Section Ryan Chappell, Draka Communications, looks at the evolution of multimode fiber, examines its current usage and shares predictionson its future Available on-demand at: http://www.brighttalk.com/webcast/7182/play OSP Magazine Webinars OSP Magazine (OSP as in outside plant telco) is now offering a number of interesting webinars that cover fiber topics, including network design and specialized components. http://www.ospmag.com/events/web/ Multimode Fiber Characterization Launch Condition Considerations - new ap note from JDSU JDSU Reference Guide to Fiber Optic Testing – Volume 2 Published  The second volume of the JDSU series on fiber optic testing has been published. Volume 1 focused on Basic Fiber testing and Volume 2 is geared toward fiber optic installers, project managers, telecom technicians and engineers who need to understand fiber networks. Volume 2 also covers Chromatic Dispersion, Polarization Mode Dispersion, Attenuation Profile and Fiber Link and Network Characterization. A 3rd volume, a glossary of fiber optic terms, is also available for download. This is a "MUST HAVE" for all fiber optic techs. Download your free copies here. We used this book as one of our references in creating a new page in the FOA Online Reference Guide on chromatic dispersion (CD) and polarization-mode dispersion (PMD). Careers in Fiber Optics: Brian Smith. A 1998 book on fiber optic jobs is a bit dated, but a free overview is on Google Books and worth a look at it online. Dirt! As much as 70% of the problems associated with deploying fiber to the home result from something as simple as dirty connectors according to JDSU. Telephony Online. US Conec's videos on cleaning fibers - show's the results of proper cleaning. Good Technical Websites American Polywater (http://www.polywater.com/) has one of the best technical website for cable installers. Here is a rundown on some new material on their site. Cable Installation using "Push" or "Push/Pull" Polywater's new Pull-Planner™ 3000 Software allows a "pushing force" variable in pulling tension calculations. Read a White Paper that quantifies the push contribution and compares calculation results to field experience. -- http://www.polywater.com/pushing.pdf Pulling Cable Through Water? Read a Product Spotlight on Polywater® + Silicone™, Polywater's new generation underground lubricant. Continued reduction of friction when pulling through water is only one of the unique features of this lubricant. -- http://www.polywater.com/NNNBSL.pdf Check out their website, especially “Videos,” “Engineer’s Corner” and “Calculators.” http://www.polywater.com/NNNBSL.pdf  " Heard on the Street" is a monthly online newsletter from Frank Bisbee of Communications Planning Corporation that covers the telecommunications and cabling businesses. Each month includes news from manufacturers, trade associations and professional societies like the FOA. You can read the current issue and back issues online.  JDSU has announced the See the Light webinar series, a four-part program designed for anyone involved in the installation, maintenance, and repair of fiber optic systems. It begins with fiber inspection and cleaning and then covers the basics of fiber testing. The webinar series then continues with the more advanced optical time-domain reflectometer (OTDR) and fiber local area network (LAN) testing challenges. More information on the series. IGI is offering a series of webinars on topics of interest to those in the communications industry. You can join them live ir download from the archives. IGI WEBINAR ARCHIVES UP AND RUNNING - VISIT TELECOMBRIEFINGS.COM TO DOWNLOAD! IGI, a major market research and technology reporting company (the "Active Optical Cables" below) is offering a a free one year subscription to one of our fiber optics newsletters to FOA members. All they have to do is to send IGI an e-mail stating which newsletter they would like to get. See http://www.igigroup.com/nl.html for a listing of IGI Newsletters. A Fiber Optic Tester In Your Pocket? (See the video on Yes! The camera in your cell phone is sensitive to infrared light - lots more than your eye - and can detect light in an optical fiber or from a transmitter. Chris Hillyer,CFOT/CFOS/I, Master Instructor, Northern California Sound & Communication JATC sent us some photos showing how this works and the following description.   "Your cell phone camera's image sensor can read IR light. It uses this technology to help take pictures at night. In the advanced audio and CCTV field they have been using the smart phone camera to trouble shoot problems in IR communications. The human eye cannot see the IR light emitted by let’s say a remote control. Well up until now we would always say that the remote is out of batteries, or either the IR transmitter or IR receiver was not working properly. Now we can use your smart phone camera to see the IR light emitted by the IR transmitter. All you have to do is turn on your camera function on your smart phone and hold it up the remote control and push any button. The cameras screen will show the IR light. Now back to Fiber Optics. If you follow the same principals of the last paragraph, let’s say you wanted to check if a fiber port was energized. You can either use the card that is supposed to show you in a few seconds that the port was hot. Or you could plug in your meter, in this case it takes some time to find the card or if you don’t have your meter handy. Just pull out your smart phone turn on the camera and hold it over the port. If it is hot you will see a bluish white dot in the fiber bulk head (see attached pictures)." We tried this ourselves and found our camera phone very sensitive at 850 nm but as expected less so at 1300 nm, like all semiconductor detectors. Our phone could still see 1300 nm sources at around -20 dBm, making it very useful even for LED sources, and of course, perfect for lasers. OFSTP-14 Update OFSTP-14 is the TIA standard for testing installed multimode fiber optic cable plants which has been around more than 20 years and is the one TIA standard probably most familiar to contractors and installers. The TIA has adopted IEC 61280-4-1 as the replacement of OFSTP-14. Most of the two documents is the same, with some important exceptions.

We are creating a web page to explain the differences and will give you a link shortly. In the meantime, continue testing as usual. The FOA reference website is now online. New sections have been added on Outside Plant Fiber Optics, fusion splicing and mechanical splicing. Check out the current Table of Contents. This month, we added a page on "polarity" for fiber optic networks.

Tiny Fusion Splicer Would Fit In Your Pocket  Aurora Optics has created a fully automatic fusion splicer, called the MiniMod, that is made in 2 parts and the splice head is only the size of a digital camera. Aurora says the splicer's size makes it usable in extremely difficult and hard-to-reach environments. The MiniMod is operated from a remote control unit, connected by an umbilical cable. This setup enables the splicer to offload functiions that do not have to be at the fiber location, such as display monitor, control keypad, microprocessor and power supply. Only those functions directly affecting the fiber (imaging system, precision fiber positioners and high-voltage fusion arc) are kept in the splicer itself.  Aurora says that despite its small size, the MiniMod maintains high levels of sophistication. The splicer's features include three-axis auto alignment, automatic fiber placement, sub-pixel image processing, sophisticated arc fusion control and splice-loss estimation. The MiniMod works in any orientation, including upside-down, and meets MIL-PRF-28800 environmental specifications including ambient temperature from -10 to +55 degrees Celsius, relative humidity from 0 to 95 percent and altitude to 5000 meters. Typical loss for a singlemode fiber is 0.02, according to Aurora. Aurora Optics AFL Offers Neat Solution For Prepolished Connectors Prepolished connectors have gotten much better recently as manufacturers move to using quality cleavers for fiber preparation and VFLs to verify a proper splice termination. Corning has incorporated these into their Pretium kits with a VFL and GO/NOGO indicator in the termination tool. Now AFL has another solution. On their FAST connectors, they have a clip that functions as an indicator for the VFL and the crimp tool for the fiber. Watch this video for a better explanation. (Read our "test drive" of the Corning Unicam above.) A Cable Tie That's Fiber Friendly We're always warning installers not to tighten cable ties too tightly around fiber optic cable (or UTP copper cable either!) A better choice is the hook and loop fastener ties (Velcro is one trade name), but there is another type, the Mille-Tie. It's an open tie that can be used at any length, then cut off and the remainder used also. Take a look a the video to see how it works. Mille-Tie Video: http://www.youtube.com/watch?v=QPVTQGKmcvE The FOA has created a new Reference Guide page on bend-insensitive fiber. Corning ClearCurve® Bend-Insensitive (BI) Optical Fiber Compatible With Other Multimode Fiber Types See the Corning Web Pages On BI Fiber for more details. Corning ClearCurve® multimode optical fiber combines the high bandwidth performance of laser optimized fiber types, e.g. Corning InfiniCor® SXi (OM2), InfiniCor®SX+ (OM3) and InfiniCor® eSX+ (OM4) fibers, with advanced macrobending performance. ClearCurve® multimode is specifically designed for Enterprise networking applications such as LAN (local area network), SAN (storage area network), campus networks and Data Centres. All Corning ClearCurve multimode fibers are able to support transmission speeds of 10/100 Mb/s through to 10Gb/s and are ready for next generation speeds of up to 16/40/100 Gb/s. • ClearCurve OM2, OM3 and OM4 multimode fibers are compliant and fully backwards compatible with all relevant industry standards;

multimode installed base

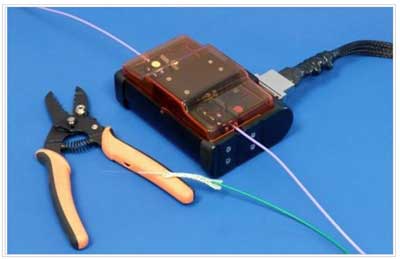

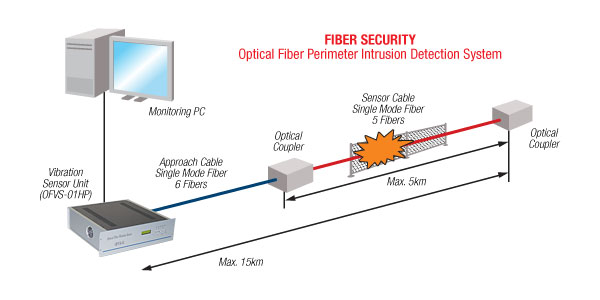

• ClearCurve multimode fiber may be spliced or connectorized to conventional 50/125 fiber types with commercially available equipment and established practices and methods; no special tools or procedures are required. Testing has been done with Corning fibers and various competitive standard and bend insensitive fibers and no issues were observed. Corning has stated that all their MM fiber will be BI fiber and has created an app note on how to implement the TIA-spec mandrel wrap with this fiber. Here is the complete information reported in the FOA April Newsletter. AFL Launches Fiber Security™ Perimeter Intrusion Detection System New system incorporates fiber optic sensing cable and vibration sensor unit  AFL announces the release of its optical fiber perimeter intrusion detection system, Fiber Security. While new to the US market, this system has been deployed more than 40 times in Japan and Canada by AFL's parent company, Fujikura Ltd. Fiber Security utilizes a fence-mounted fiber optic cable coupled to a sensing unit that analyzes the magnitude and pattern of vibrations at the fence. The sensing unit's unique algorithm is capable of discerning high and low level vibrations and filtering out vibrations not associated with intrusions. Up to 100 individual zones can be set up using the software, and the individual zones can have different levels of sensitivity as needed. Detection accuracy is +/- 2% over the entire sensing length of the perimeter, up to 3.1 miles in length while operating up to 6.2 miles from the sensing unit. No power is required in the field with only standard 110V power necessary at the sensing unit and PC. A user-friendly graphical interface depicts the property and the perimeter giving visual representation of where an intrusion is detected. AFL's Fiber Security is highly successful at detecting multiple intrusion events such as climbing, cutting, or lifting a fence. Environmental noise such as traffic, trains, or planes, and wind and rain are actively filtered out by the algorithm to reduce false positives while maintaining sensitivity. The system can be integrated with video systems and other technologies such as passive IR sensors via Ethernet, dry contactors, or RS232 connections. Fiber Security can send remote alerts via e-mail for facilities that do not have full time personnel on site. Highly dependable laser diodes coupled with a completely passive optical sensor translate to low maintenance costs over long periods of operation. With the ability to function as a standalone system or as part of an integrated security solution, AFL's Fiber Security is now available to meet your perimeter intrusion detection needs. For additional information, visit www.AFLtele.com/go/FiberSecurity. Benchtop Connector Cleaner  FerrulePro™ is the world’s first fully automated benchtop fiber connector cleaner for laboratory and cable production environments. It automates the final cleaning of all types of terminated fiber products, a critical task where performance once depended largely on the production line worker’s skill. Fiber connectors can be cleaned in 3 seconds cycle - eliminating the need for re-cleaning after post production inspection. More. End-Of Summer Sale on FO Toolkits at TTTP Save 25-40% off Advanced Fiber Solutions fiber optic installation toolboxes with test equipment. Go here. New AFL Cleaver Does Regular and Angle Cleaves Both cleavers incorporate an easily replaceable blade and cleave 250µm and 900µm fibers. They are easy to use, simple to adjust and extremely consistent. More details. Draka Expands Bend-Insensitive Fiber Line A large number of Draka fibers are available with BendBright-Elite fiber. In North America, BendBright-Elite is available in premises and outside plant cables. Draka introduced the BendBright family of bend insensitive fibers in 2002 and has since expanded the product family to four versions of bend insensitive fiber, spanning both singlemode and multimode types:

But it means changes in the way you test with it! Corning announced that effective April 1, 2010, ClearCurve® multimode optical fiber will become its standard 50-micron multimode fiber product offering. "ClearCurve multimode fiber is the world’s first laser-optimized, high-bandwidth, multimode fiber to withstand tight bends at 7.5 mm radius with substantially less signal loss than traditional multimode fibers. ClearCurve multimode optical fiber was first introduced by Corning in Jan. 2009 and has been validated through broad customer acceptance of the product. Traditionally, when an optical cable experiences tight bends, some of the light can escape from the fiber core and part of the signal can be lost. Corning ClearCurve multimode fiber is designed to keep the light in the fiber core, even under tight bends, and better maintain the integrity of the optical fiber signal. “Corning’s 50-micron multimode fiber customers will now benefit from superior bend performance. This will result in faster and more efficient optical cable routing and installation, and significantly higher spare operating margin, at no additional cost,” said Martin J. Curran, senior vice president and general manager, Corning Optical Fiber. Corning ClearCurve multimode fiber meets or exceeds the OM2, OM3 and OM4 industry standards for high-bandwidth, laser-optimized multimode fiber. Corning will demonstrate the performance of ClearCurve multimode optical fiber from March 23-25, 2010, at OFC/NFOEC in San Diego. Detailed product specifications are available at www.corning.com/clearcurve." When You Test... Most standards call for a "mandrel wrap" mode conditioner on your launch cable. The Corning announcement made us wonder what happens with this bend-insensitive fiber if you wrap it around a standard mandrel - it should not act the same as regular 50/125 fiber. We contacted our friend the Marketing Manager for the product at Corning and he confirmed our suspicions. The difference in the bend sensitivity of the fiber requires a much smaller mandrel, only 6 mm in diameter, to have the same effect. This is detailed in Corning Application Engineering Note "Multimode Fiber Considerations for Test Jumpers, AEN 131, Revision 2" available from Corning. Add OCC to the list of cable manufacturers offering "bend-tolerant" cables. Draka too.(Lightwave) AFL Introduces 3 new Noyes OTDRs(Lightwave).

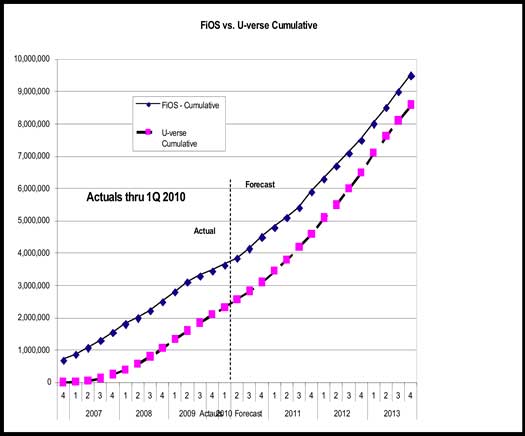

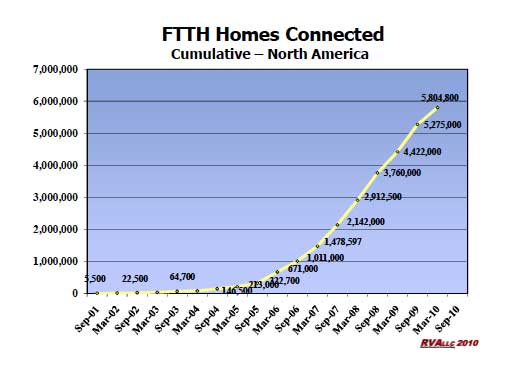

They're still being used for high power laser delivery - up to 80-100W! Seikoh Giken has even introduced some new ones. Used Test Equipment – Buy or Sell http://www.testequipmentconnection.com/ Have you read the FOA Tech Topics on Cleaning? More links on cleaning: Cleantex Alco Pads FTTH or FTTC? That's the competition between Verizon FiOS and and AT&T U-Verse. The graph below, courtesy of IGI from their ecent report, “FiOS vs. U-verse; Architecture, Marketing, and Technical Considerations,” shows FiOS ahead but the gap narrowing as Verizon winds down their extremely aggressive FTTH program.  Woodstock Goes FTTH - Woodstock Telephone Company in Minnesota, that is. Delivering up to 75 Mb/s over a 450 square mile service area. (TellLabs) Residents of Ashby de la Launde, a small village in Lincolnshire, UK, will soon be able to install 100-Mbps fiber-optic broadband into their homes via the FTTH network. Lightwave. Nearly 60 homes and three businesses have started on-site digging to connect to the FTTH network to be installed around the village. The project involves the community working together to establish a privately funded network. New Report : FTTH connections continue to grow in North America You can download and read the entire report from the FTTH council website. http://www.ftthcouncil.org/sites/default/files/RVA.FTTH_.Apr10.040712Final.pdf Testing FTTH JDSU shows how to test a PON with an OTDR: http://www.jdsu.com/other-literature/PON-OTDR_fop_an_ae.pdf US FTTH Connections Continue To Grow  According to a just released FTTH Council Report prepared by RVA, FTTH connections continue to grow in North America - 99% of which are in the US, but growth seems to be slowing, probably a consequence of the current economy. Much of the FTTH deployment in the US has been due to Verizon's $23 billion investment in FTTH, but the report noted that FTTH is now being deployed by more than 750 service providers across North America. Most of these service providers are small, independent telephone companies that are replacing their copper lines with end-to-end fiber to ensure their future competitiveness as broadband providers. Of the service providers not yet offering FTTH, a majority say they are likely to soon. You can download and read the entire report from the FTTH council website. http://www.ftthcouncil.org/sites/default/files/RVA.FTTH_.Apr10.040712Final.pdf David Chaffee's FTTH Prism Newsletter is Online (archives are at bottom of the linked page)

|

What Is The FOA? Hear FOA President Jim Hayes tell the FOA Story in a 2-part interview by Sound & Video Contractor Contributing Editor Bennett Liles. It tells about the FOA history, goals and achievements. Part 1: http://svconline.com/podcasts/audio/fiber_optic_association_part1/index.html. Part 2 http://svconline.com/podcasts/audio/inside-fiber-optic-association2-0924/index.html. |

|

Digging Safely (Read the FOA Tech Topic) There is a new toll-free "call before you dig" number: 811 See www.call811.com for more information National Fiber Optic Protection Summit: By the "811" group. March, 2008 in Vegas.

|

|

|

New FOA Jobs Website We get many questions from CFOTs, students at FOA-Approved schools and others contemplating getting into the fiber optic business regarding jobs in fiber optics - and how to find them - so we’ve created a new web page to share some information we've gathered about jobs in our industry. The information is designed to help you understand what jobs are available in fiber optics, how to find them and apply for them. While the overall economy is pretty bad - you've probably heard that there are 5 times as many people unemployed in the US as there are jobs available, telecom is a bright spot - broadband is a major focus of stimulus spending in the US and countries around the world are building fiber networks as fast as possible. Even wireless companies have to build fiber for their backhaul. Cities are installing fiber linked surveillance cameras and smart traffic lights. Fiber is the link making Smart Grid possible. Companies like Allied Fiber are building large private networks. Telecom is one of the fastest growing businesses worldwide. If you are looking for a job in fiber optics, here is the FOA's guide to jobs. The FOA has created a group on A list of 10 ways to get your resume noticed from Marketplace on NPR Jobs Created As Part of Stimulus-Funded Projects The federal government is spending 7.2 billion dollars on the Broadband Technology Opportunities Program. This money is working it's way into the economy and hopefully will provide jobs. You can track recovery dollars and look for job opportunities on this website: www.recovery.gov Go to "opportinities" link then "jobs". You will see a section “find recovery jobs” – enter “fiber optic jobs California” or wherever you are and review what comes up. One of the projects funded by stimulus money is the1100 mile network of Maine Fiber Company Inc. which has selected nextGen Telecom Services Group Inc. as the installation contractor. CFOTs: NextGen has a link on their website for applying for jobs Inspectors for a fiber installation project for Metrolink (commuter rail) to take place in Orange County, CA. The duration of the job is expected to be 18 months. SCRRA (Metrolink) and OCTA will begin a communications infrastructure rehabilitation project along the railroad right of way in Orange County, CA. The work will involve fiber optic cable installation, fiber termination, microwave installation, testing and turn up of the respective networks. Pacific Railway Enterprises is seeking personnel to perform inspection for this important project. The expected job duration is 18 months, but there is a possibility candidate may be retained by Pacific Railways Enterprises for additional work if the fit is good for both the employer and employee. Candidates with fiber inspection OR installation/test experience are preferred. Candidates will be sent to a fiber inspection course which would require approximately 2 weeks of travel. This work will occur along an active railroad right of way, therefore completion of railroad safety training will also be required prior to beginning work. The candidate could also be subject to a possible background check and random drug and alcohol screening. Daily inspection duties will include: installation and test observations, recommendations, and reporting, referring to contract documents for contractor adherence, producing written reports (activity tracking), performing calculations and assistance in verifying contractor payments for work progress, taking progress photographs, producing written exceptions to contractor work performed if deemed necessary, and assisting the Resident Engineer with RFIs, accident or injury reports, and attending meetings when required. Work is paid hourly and will be up to 50 hours per week, and may include some night work. Work days will be determined by the contractor and may include Saturdays or Sundays. All candidates interested for this project should email their resume to Jennifer Purcell at japurcell@pacrail.com. The hiring window for this project is narrow-- if interested please contact PRE as soon as possible. A profile of Pacific Railway Enterprises at www.pacrail.com Business Development Manager OFS – Specialty Photonics Division From its roots in Bell Laboratories through Lucent Technologies, OFS has emerged as an innovative, diversified leader in the optical fiber marketplace. The Specialty Photonics Division, in Avon, CT, provides critical components, specialty fiber, cable & assemblies to myriad applications within the telecom, industrial, medical, geophysical, transportation & government, aerospace and defense markets. Position Profile Reporting to the Vice President, Marketing & Sales, the Business Development Manager will play a key role as a strategic visionary within the organization. The incumbent shall gain a full understanding of the current technological capabilities and then provide research & market analyses regarding new growth opportunities in current and emerging markets & technologies. The incumbent shall be able to focus on the future – 5-10 years out – to determine what the market of the future will demand, be able to effectively plan and communicate these ideas to senior leadership, and take a leadership role in organizing the business activities around these goals to allow OFS to position itself to take full advantage of new and emerging external opportunities for growth. Key Responsibilities: • Develop/utilize robust analysis tools, business processes and an overall financial model for a well balanced growth strategy. Include M&A, partnerships and JV’s, and long and short term product development. Work with individual marketing staff to validate, disseminate and update. • Provide in depth research and market analyses regarding new growth/new product opportunities that the market will be calling for 5-10 years out • Plan & execute customer visits to reach out to business and research science contacts to explore new possibilities for collaboration • Interact with current sales and marketing team and engineering group to understand current position & challenges • Determine strategies for external growth through collaboration, joint venture, M&A, etc. • Formulate plan to sell the benefits of these strategies to upper management • Lead the charge to communicate & launch new development activities throughout the sales, marketing, R&D, & business teams internally Qualifications: The ideal candidate will be both analytical & extroverted with a technical background to allow for open and easy dialog regarding highly technical product applications. The incumbent shall have strong business acumen to be able to effectively lead complicated business negotiations in the best interests of OFS. • 4-year technical degree, advanced masters degree (technical or business) preferred • At least 4 years technical product development, sales or marketing (from concept through introduction phase) • Excellent listening & communication skills • Forward thinking, visionary Case Study: Please provide a detailed narrative to illustrate how you have researched & sought out current and prospective clients to determine new product requirements and/or determine market demand for new technologies or new applications for your current products. How were you able to promote the ideas internally and then lead the charge to get new business activities underway that focused on the new initiatives? MSI Process: If you are interested in moving forward in the MSI Process, for evaluation related to this outstanding opportunity: 1. Amend the document by fully describing in bold print your relative expertise after each of the responsibilities and qualifications “bullets” and addressing the case study. 2. Return amended document along with a copy of your updated resume and we will contact you to arrange an interview. Contact Information: Sean Murphy, CPC, President sean@msi1.com 860-761-3232 Rebecca Wareing, CPC rwareing@msi1.com 860-761-3239 Do listings in the FOA Newsletter Work? Here's feedback: "We did great! We have over 15 interviews next week." "Your newsletter generated a significant number of applicants and we have filled the position." |

|